Automatic detection system and method thereof

A technology of automatic detection and detection area, which is used in measurement devices, material analysis by optical means, instruments, etc., which can solve the problems of missed inspection, prolonged detection time, and reduced production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The implementation of the present invention will be described in more detail below with reference to the drawings and reference numerals, so that those skilled in the art can implement it after studying this specification.

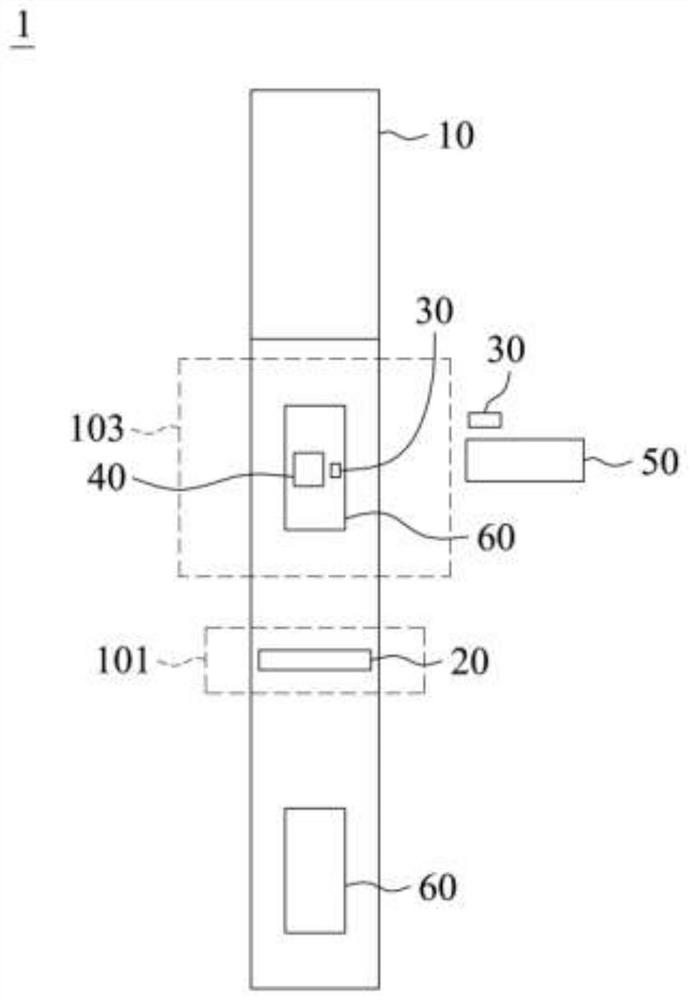

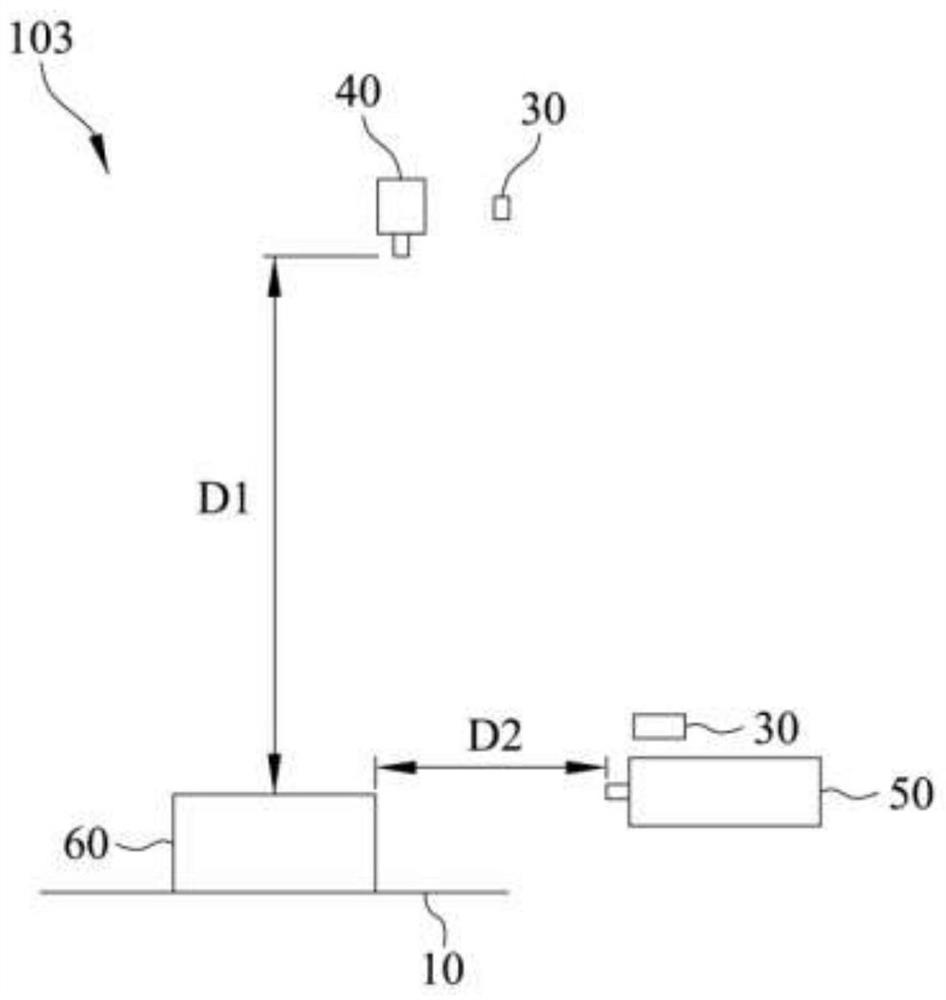

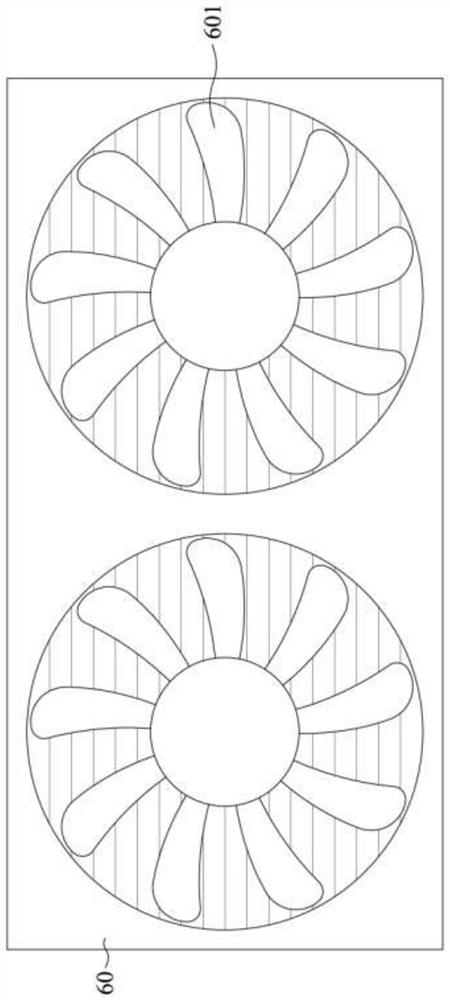

[0044] figure 1 It is a schematic top view for illustrating the structure of an automatic detection system according to an embodiment of the present invention. Please refer to figure 1 , in one embodiment of the present invention, the automatic detection system 1 includes a production line 10, at least one sensor 20, at least one supplementary light element 30, a first photographing device 40, a second photographing device 50, and a computer device ( not shown in the figure).

[0045] The production line 10 includes a sensing area 101 and a detection area 103 . At least one sensor 20 is set at a position adjacent to the production line 10 at the sensing area 101, such as above, on the side of the production line 10, etc., in the figure 1 Middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com