Ultrasonic fault detection method for heat check compound filling defect of thick-wall aluminum alloy pipe

A thick-walled tube, ultrasonic technology, applied in the field of aluminum alloy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

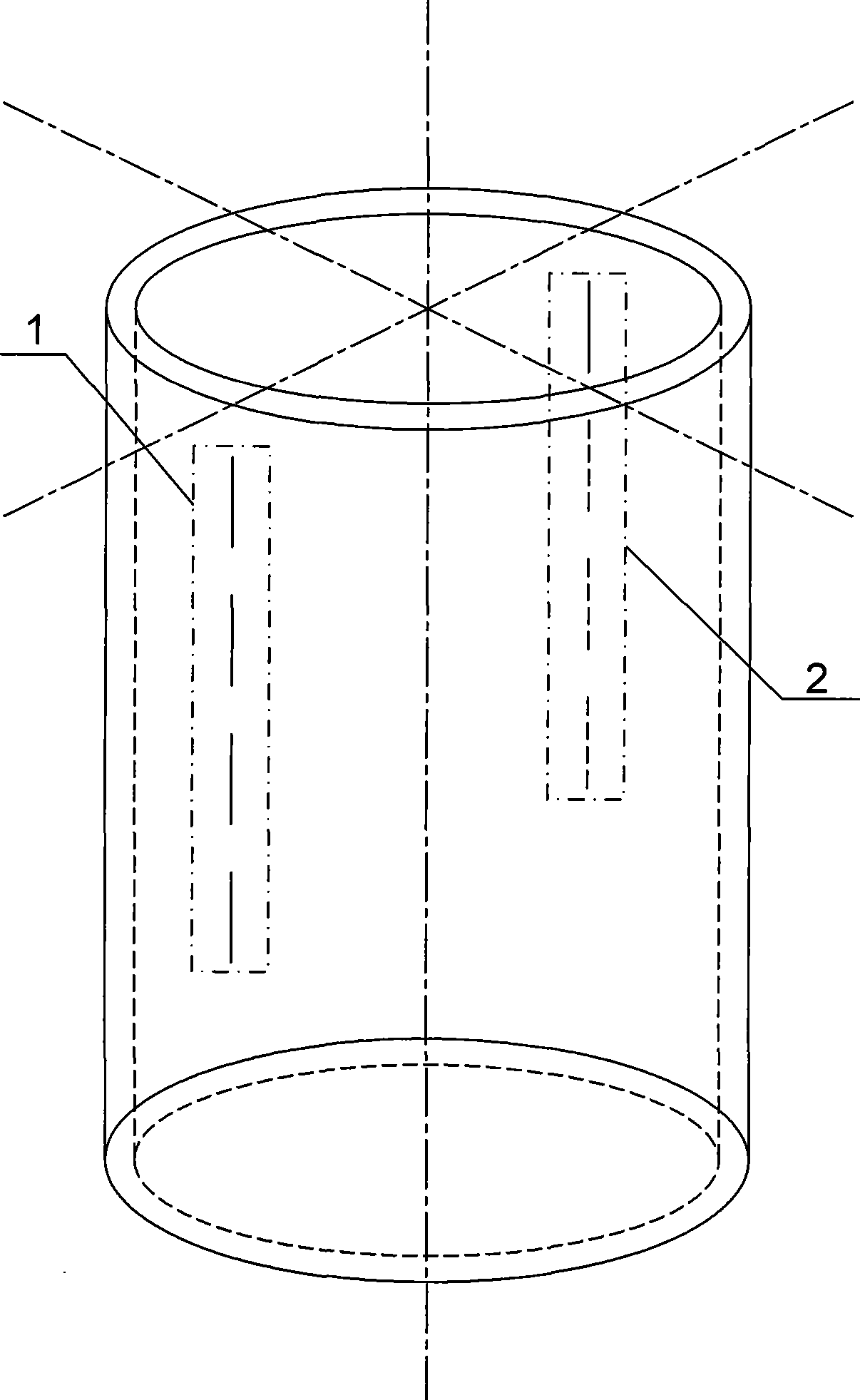

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment, the steps of this embodiment are as follows:

[0016] Step 1: Select an ultrasonic flaw detector;

[0017] Step 2: Select the ultrasonic probe and the grinding of the probe curvature: select the ultrasonic probe and use fine sandpaper to grind the contact surface between the probe and the inspected part, so that the curvature is consistent with the curvature of the outer surface of the inspected pipe;

[0018] Step 3: Selection of comparative samples: Cut a 150mm length from a non-defective thick-walled tube of the same specification and alloy as a comparative sample;

[0019] Step 4: Manufacture of artificial grooves: engrave a group of longitudinal artificial grooves 2 on the inner surface and a group of longitudinal artificial grooves 1 on the outer surface on the comparison sample, and the positions of the longitudinal artificial grooves on the inner and outer surfaces are symmetrical alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com