A kind of magnetic pearlescent pigment and preparation method thereof

A pearlescent pigment and magnetic technology, used in inorganic pigment processing, chemical instruments and methods, fibrous fillers, etc., can solve the problems of high equipment and operation requirements, difficult to grasp the proportion and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

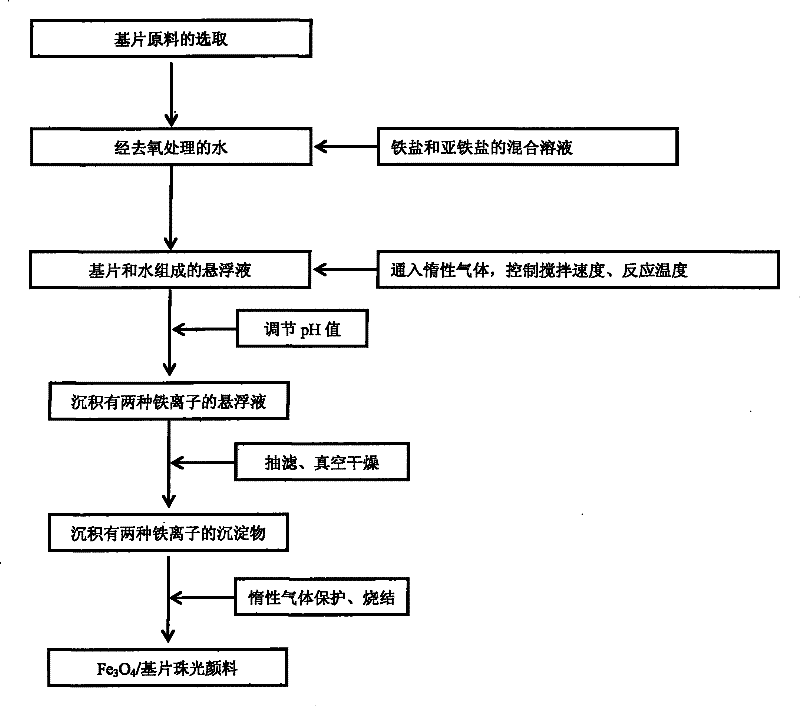

Method used

Image

Examples

Embodiment 1

[0032] Put 100ml of boiled deionized water and 10g of mica in a beaker and stir it magnetically to form a suspension. In the case of nitrogen, a certain molar ratio of FeCl was pumped with a peristaltic pump 3 ·6H 2 O and FeCl 2 4H 2 The mixed solution of O is dropped into the beaker drop by drop, and the pH value is adjusted to be constant with a pH regulator. In this embodiment, five pH values are set, namely pH=8.9, pH=9.2, pH=9.5, pH=9.8, pH =10.1, fix the other 4 factors, that is, the reaction temperature t=30°C, the NaOH concentration is 0.5mol / L, Fe 3+ :Fe 2+ =1.364:1, the stirring speed is υ=138r / min~51r / min, after the reactants are added dropwise, continue to stir for 0.5 hours to make the reaction more complete; then suction filtration, washing, 60 ℃ vacuum drying; finally in the tube In the furnace, calcine at 350°C for 3 hours under nitrogen gas. Fe under 5 different pH values can be prepared altogether by the method of this embodiment 3 o 4 / Mica pear...

Embodiment 2

[0034] Put 100ml of boiled deionized water and 10g of mica in a beaker and stir it magnetically to form a suspension. In the case of nitrogen, a certain molar ratio of FeCl was pumped with a peristaltic pump 3 ·6H 2 O and FeCl 2 4H 2 The mixed solution of O is dropped into the beaker drop by drop, and the pH is adjusted to be constant at 9.2 by a pH regulator. In this embodiment, five NaOH concentration values are set, which are 2mol / L, 1.5mol / L, 1.0mol / L, 0.5 mol / L, 0.25mol / L, fix the other three factors, that is, the reaction temperature t=30℃,, Fe 3+ :Fe 2+ =1.364:1, the stirring speed is υ=138r / min~51r / min, after the reactants are added dropwise, continue to stir for 0.5 hours to make the reaction more complete; then suction filtration, washing, 60 ℃ vacuum drying; finally in the tube In the furnace, calcine at 350°C for 3 hours under nitrogen gas. Fe under 5 different NaOH concentrations can be prepared altogether by the method of this embodiment 3 o 4 / Mica pe...

Embodiment 3

[0036] Put 100ml of boiled deionized water and 10g of mica in a beaker and stir it magnetically to form a suspension. In the case of nitrogen, a certain molar ratio of FeCl was pumped with a peristaltic pump 3 ·6H 2 O and FeCl 2 4H 2 The mixed solution of O is dripped in the beaker drop by drop, and utilizes the pH adjuster to regulate pH=9.2 constant, present embodiment sets 5 The molar concentration ratio of , fix the other 3 factors, that is, the reaction temperature t = 30 ℃, the NaOH concentration is 0.5mol / L, the stirring speed is υ = 138r / min~51r / min, after the reactant is added dropwise, continue to stir for 0.5 hours, so that The reaction is more complete; then suction filtration, washing, and vacuum drying at 60°C; finally, calcination in a tube furnace at 350°C for 3 hours under nitrogen. A total of 5 different Fe at a molar concentration ratio of 3 o 4 / Mica pearlescent pigment. The performance test results of the prepared pigments are shown in Table 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com