A kind of preparation method of metal-graphene composite electroplating material

A graphene composite and graphene technology, applied in electrolytic coatings, electrodes, coatings, etc., can solve the problems of obvious graphene agglomeration, insignificant effect, rough surface of composite coating, etc., and achieve the effect of avoiding agglomeration and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

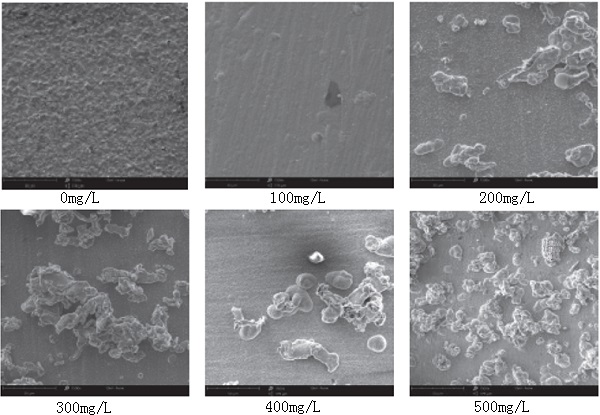

[0031] Embodiment 1, a preparation method of a metal-graphene composite electroplating material, a graphite rod is used as an anode, a substrate to be plated is used as a cathode, and the substrate to be plated is carbon steel. Then prepare the electrolyte, weigh acetamide, urea and ammonium nitrate, the three are respectively by weight percentage: 37.4wt% acetamide, 28wt% urea and 34.6wt% ammonium nitrate, at a temperature of 70 ° C Stir and melt until a transparent, clear and colorless liquid is obtained, then add 0.1mol / L nickel chloride hexahydrate to the colorless liquid, stir and dissolve to obtain a transparent and clear light green liquid, then add 25~35g / L boric acid , stirred and dissolved to obtain an electrolyte solution, and finally the pH value of the electrolyte solution was adjusted to 4 by adding hydrochloric acid. Then set the electroplating parameters for electroplating. The electroplating parameters are: temperature is 50°C, voltage is 3V and current densit...

Embodiment 2

[0034] Embodiment two, a kind of preparation method of metal-graphene composite electroplating material, anode, cathode, substrate to be plated and electrolyte are the same as embodiment one, electroplating parameters are: temperature is 50 ℃, voltage is 2.5V and current density is 20mA·cm -2 Under the condition of magnetic stirring, the stirring rate is 500rpm, the anode and the cathode are placed in the prepared electrolyte for co-deposition for 5h, and the nickel-graphene composite coating is obtained. The hardness of the composite coating is 424HV.

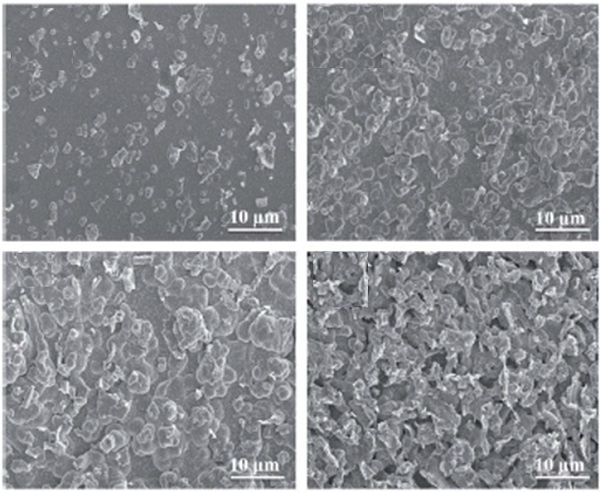

[0035] see Figure 7 , the SEM image of the surface of the nickel-graphene composite coating shown, the observation shows that the graphene is evenly distributed and compact, the surface is smooth and smooth, and there is no agglomeration phenomenon.

Embodiment 3

[0036] Embodiment three, a kind of preparation method of metal-graphene composite electroplating material, anode, cathode, substrate to be plated and electrolyte are the same as embodiment one, electroplating parameters are: temperature is 50 ℃, voltage is 2.5V and current density is 5mA·cm -2 Under the condition of magnetic stirring, the stirring rate is 500rpm, the anode and the cathode are placed in the prepared electrolyte for co-deposition for 4 hours, and the nickel-graphene composite coating is obtained. The hardness of the composite coating is 423HV.

[0037] see Figure 8 , the SEM image of the surface of the nickel-graphene composite coating shown, the observation shows that the graphene is evenly distributed and compact, the surface is smooth and smooth, and there is no agglomeration phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com