Preparation method of non-halogen flame-retarded makrolan/acrylonitrile-butadiene-styrene copolymer alloy

A technology of flame-retardant polycarbonate and styrene copolymer, which is applied in the field of polymer alloy preparation, can solve the problems of narrow range, deterioration of mechanical properties of PC/ABS alloy, and increase of cost, so as to increase the amount of charring and mechanical properties The effect of reducing deterioration and suppressing combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

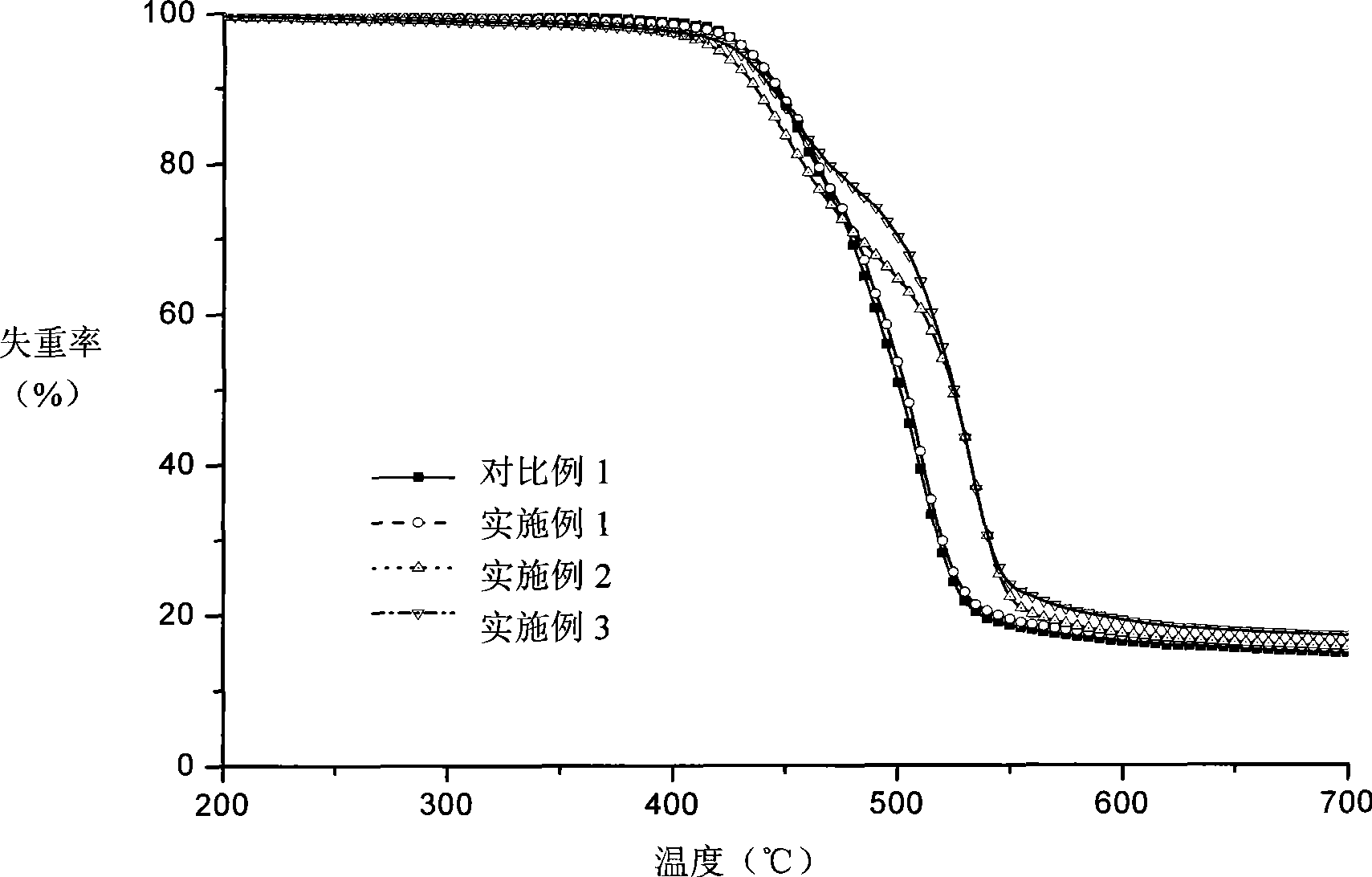

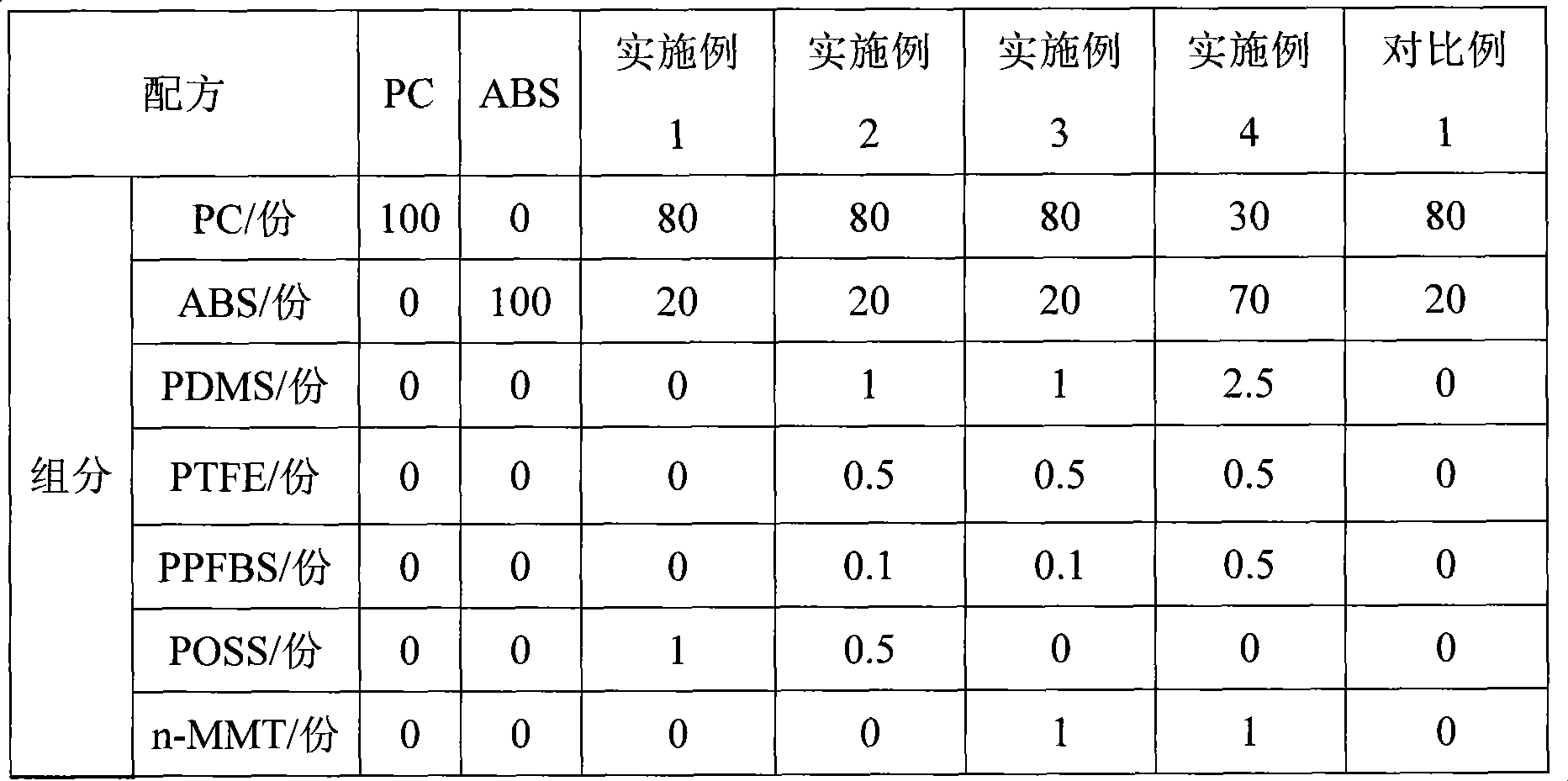

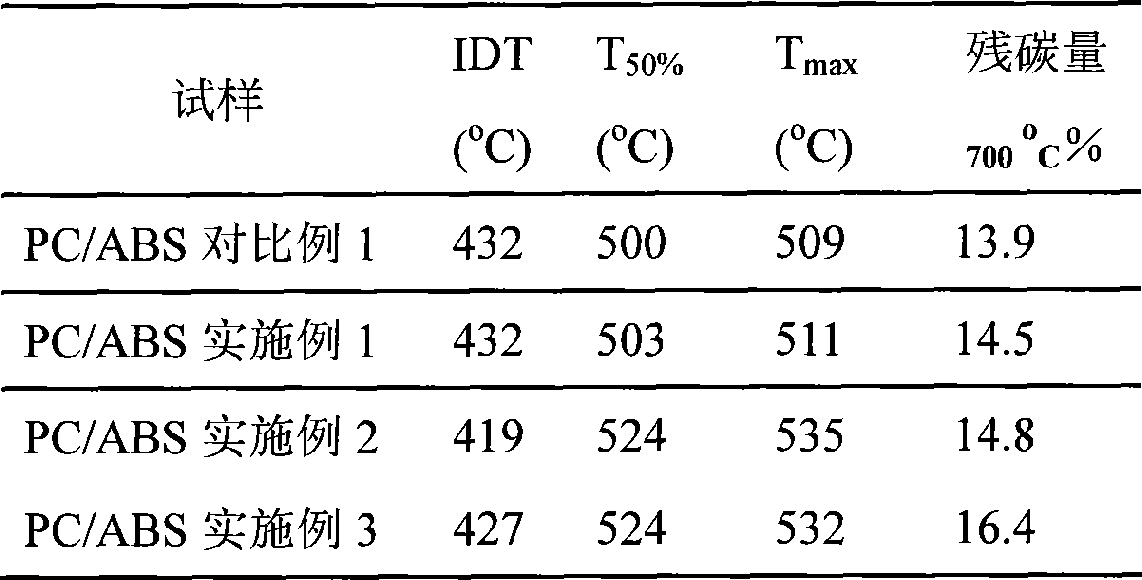

[0028] According to the formula in Table 1, dry several kinds of raw materials in a blast drying oven at 100°C for 4-8 hours, and then extrude them through a twin-screw extruder at a speed of 200-240 revolutions per minute at 230-250°C. out, cooled, dried, and pelletized to obtain a halogen-free flame-retardant polycarbonate / acrylonitrile-butadiene-styrene copolymer alloy. Afterwards, the PC / ABS alloy is dried in a blast oven at 100°C for 4-8 hours, and then made into a standard sample at 240°C by a plastic molding injection machine, and placed at 50% relative humidity and 23°C Test performance after 24 hours. The performance test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com