Porous carbon and preparation method thereof

A porous carbon and carbonization technology, applied in chemical instruments and methods, other chemical processes, etc., to achieve high yield, easy removal, and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, preparation and performance measurement of porous carbon

[0032] The experiment was repeated 3 times, and the results of performance testing were averaged.

[0033] 1. Preparation of Porous Carbon

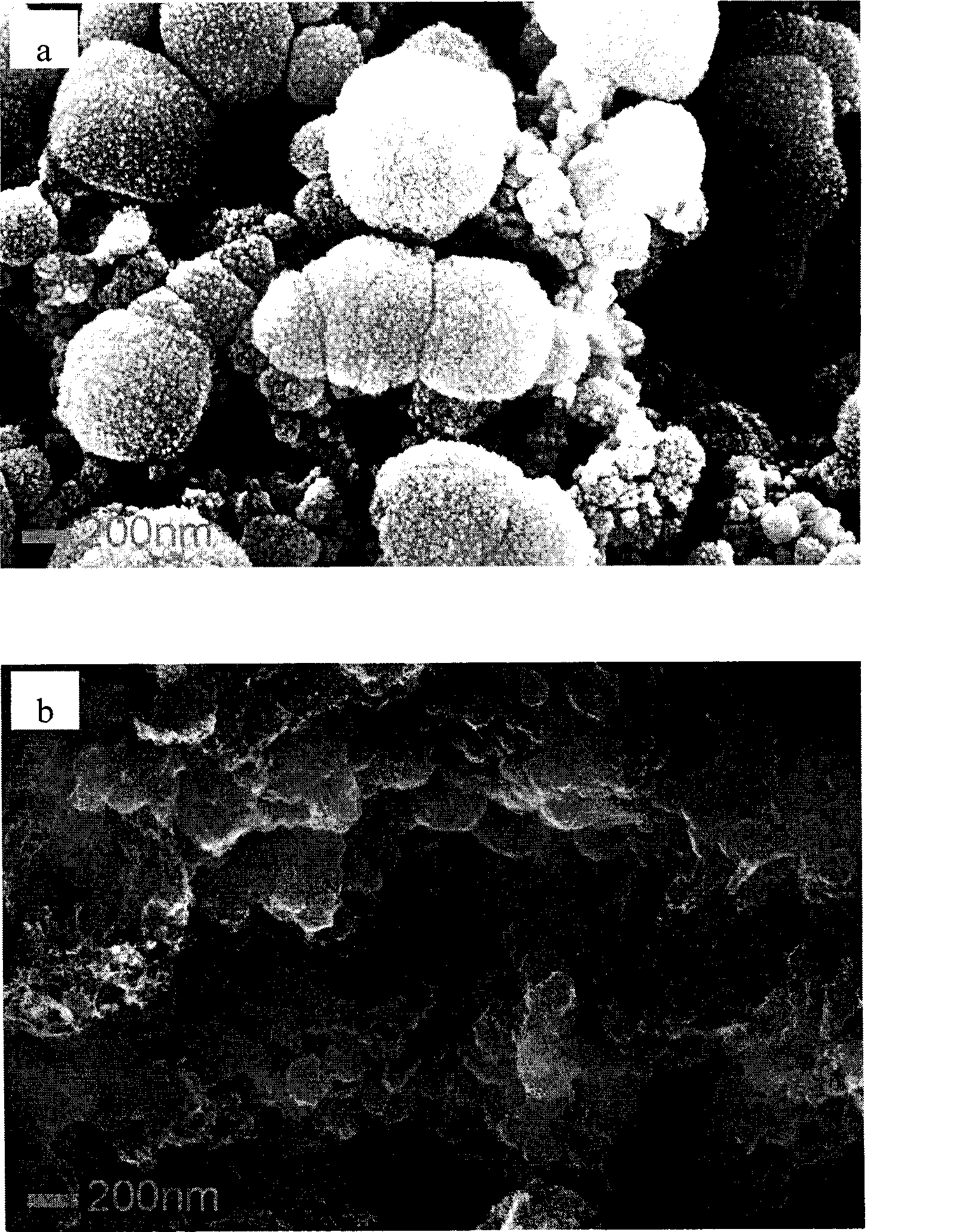

[0034] 1. Mix petroleum residue and magnesium acetate at a mass ratio of 1:3, crush it with a pneumatic mill and pass it through a 300-mesh sieve, then raise the temperature to 1000°C in a nitrogen atmosphere (nitrogen pressure is 103kPa), and carbonize for 1 hour to obtain a carbonized product . The heating rate was 5°C / min. The scanning electron microscope photo of the carbonization product is shown in figure 1 (a).

[0035] 2. Wash the charred product with 2mol / L dilute sulfuric acid, then wash it with deionized water until neutral (pH7), and dry it at 100°C to obtain product A. The scanning electron microscope photo of product A is shown in figure 1 (b).

[0036] 2. Performance determination of porous carbon

[0037] The performance of Product A is...

Embodiment 2

[0040] Embodiment 2, preparation and performance measurement of porous carbon

[0041] The experiment was repeated 3 times, and the results of performance testing were averaged.

[0042] 1. Mix petroleum residue and magnesium acetate at a mass ratio of 1:9, crush it with a pneumatic mill and pass it through a 200-mesh sieve, then raise the temperature to 700°C in a nitrogen atmosphere (nitrogen pressure is 100kPa), and carbonize for 2 hours to obtain a carbonized product . The heating rate is 2°C / min.

[0043] 2. The carbonized product was washed with 1 mol / L dilute hydrochloric acid, then washed with deionized water until neutral (pH6), and dried at 100°C to obtain product B.

[0044] 2. Performance determination of porous carbon

[0045] The properties of Product B are shown in Table 2.

[0046] Table 2 Performance of Product B

[0047] Yield (%) Specific surface area (m 2 / g) Total pore volume (cm 2 / g) Mesopore volume (cm 2 / g) Average pore size (...

Embodiment 3

[0048] Embodiment 3, preparation and performance measurement of porous carbon

[0049] The experiment was repeated 3 times, and the results of performance testing were averaged.

[0050] 1. Preparation of Porous Carbon

[0051] 1. Mix the petroleum residue and magnesium acetate at a mass ratio of 1:5, crush it with a pneumatic mill and pass it through a 250-mesh sieve, then raise the temperature to 850°C in an argon atmosphere (argon pressure is 105kPa), and carbonize for 1.5 hours to obtain Carbonization product. The heating rate is 15°C / min.

[0052] 2. The charred product was washed with 2 mol / L dilute sulfuric acid, then washed with deionized water until neutral (pH 8), and dried at 100°C to obtain product C.

[0053] 2. Performance determination of porous carbon

[0054] The performance of Product C is shown in Table 3.

[0055] Table 3 Performance of Product C

[0056] Yield (%) Specific surface area (m 2 / g) Total pore volume (cm 2 / g) Mesopore vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com