Method for preparing semiconductor oxide micro-nano compound structure film

A micro-nano composite structure and semiconductor technology, which can be used in photosensitive devices, capacitor electrolytes/absorbers, capacitor parts, etc., can solve the problems of poor controllability and repeatability of ZnO micro-nano composite structure film materials, and achieve controllability. And the effect of strong repeatability, high solar photoelectric conversion efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

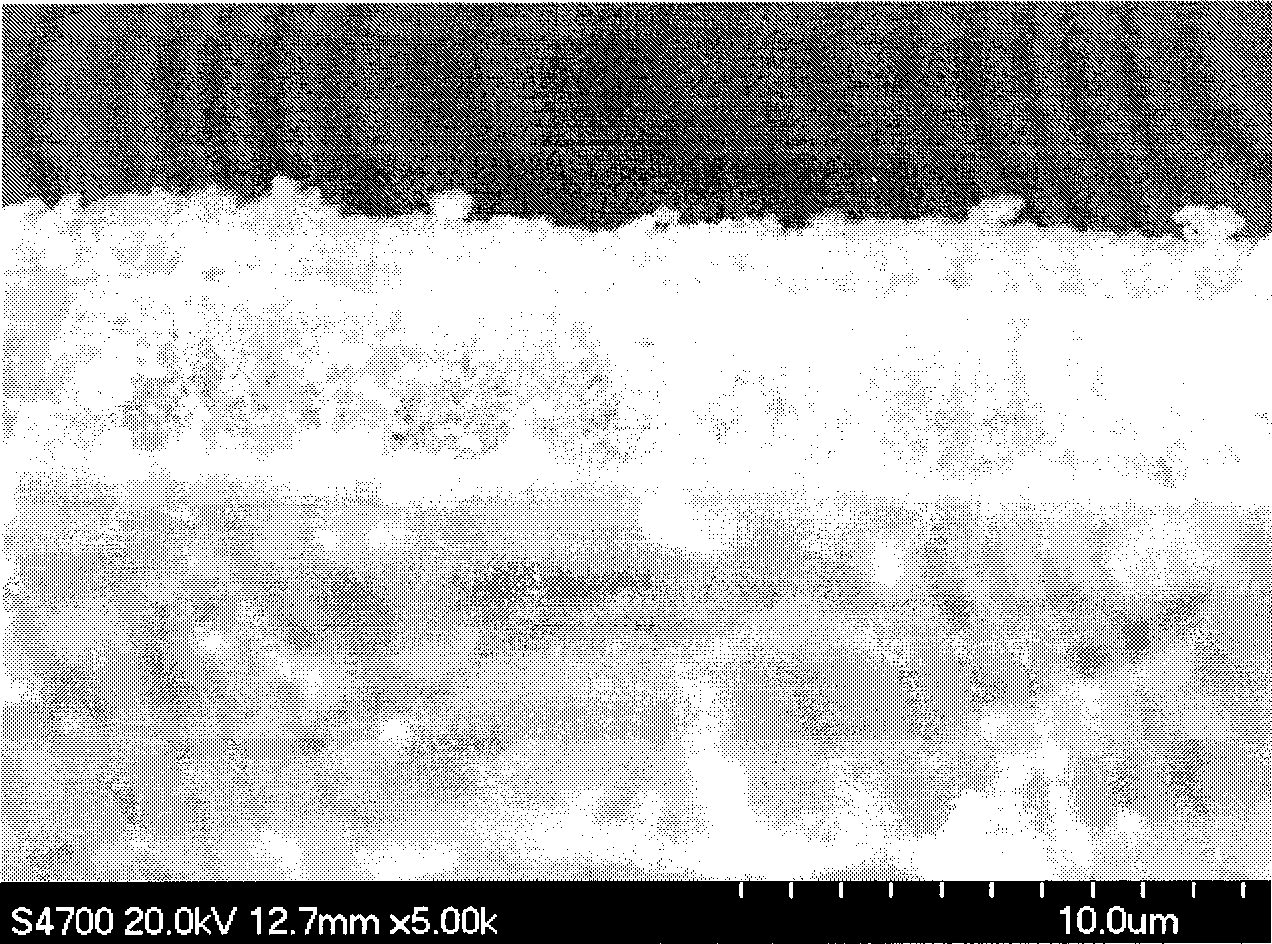

[0024] 1) Preparation of ZnO nanocrystalline film:

[0025] 1.0g ZnO nanocrystals are added into 20ml of absolute ethanol to obtain a milky white solution after ultrasonic dispersion, and the ZnO nanocrystals film is prepared on the pretreated FTO conductive glass by the drop coating method, and then the ZnO nanocrystals film is placed in a muffle furnace at 400 ℃, roasting for 2h, cooling to room temperature to obtain ZnO nanocrystalline film;

[0026] 2) Preparation of ZnO micro-nano composite thin film

[0027] Dissolve flaky micron / submicron ZnO in absolute ethanol to obtain a solution with a concentration of 0.05g / mL, and prepare a layer of large particle micron / submicron ZnO film on the surface of ZnO nanocrystalline film by drop coating method, which will have micronano The ZnO double-layer film with composite structure was placed in a muffle furnace and baked at 400 °C for 1 h, then cooled naturally to room temperature to obtain a ZnO micro-nano composite film.

[00...

Embodiment 2

[0030] 1) TiO 2 Preparation of nanocrystalline thin films:

[0031] 1.0g TiO 2 The nanocrystals were ultrasonically dispersed in 1ml of distilled water to obtain a milky white solution, and TiO was prepared on the pretreated FTO conductive glass by scalpel coating method. 2 nanocrystalline film, and then the TiO 2 The nanocrystalline film was fired in a muffle furnace at 600 °C for 5 h, and cooled to room temperature to obtain TiO 2 Nanocrystalline film;

[0032] 2) TiO 2 Preparation of micro-nano composite structure film:

[0033] Tubular micron / submicron TiO 2 Dissolve in dehydrated ethanol, the concentration that obtains solution is 1g / mL, adopt scalpel coating method with gained solution, the TiO prepared in step 1) 2 Fabrication of micron / submicron tubular TiO on the surface of nanocrystalline film 2 film, and then bake it in a muffle furnace at 600°C for 5h, and cool to room temperature to obtain TiO 2 Micro-nano composite structure film.

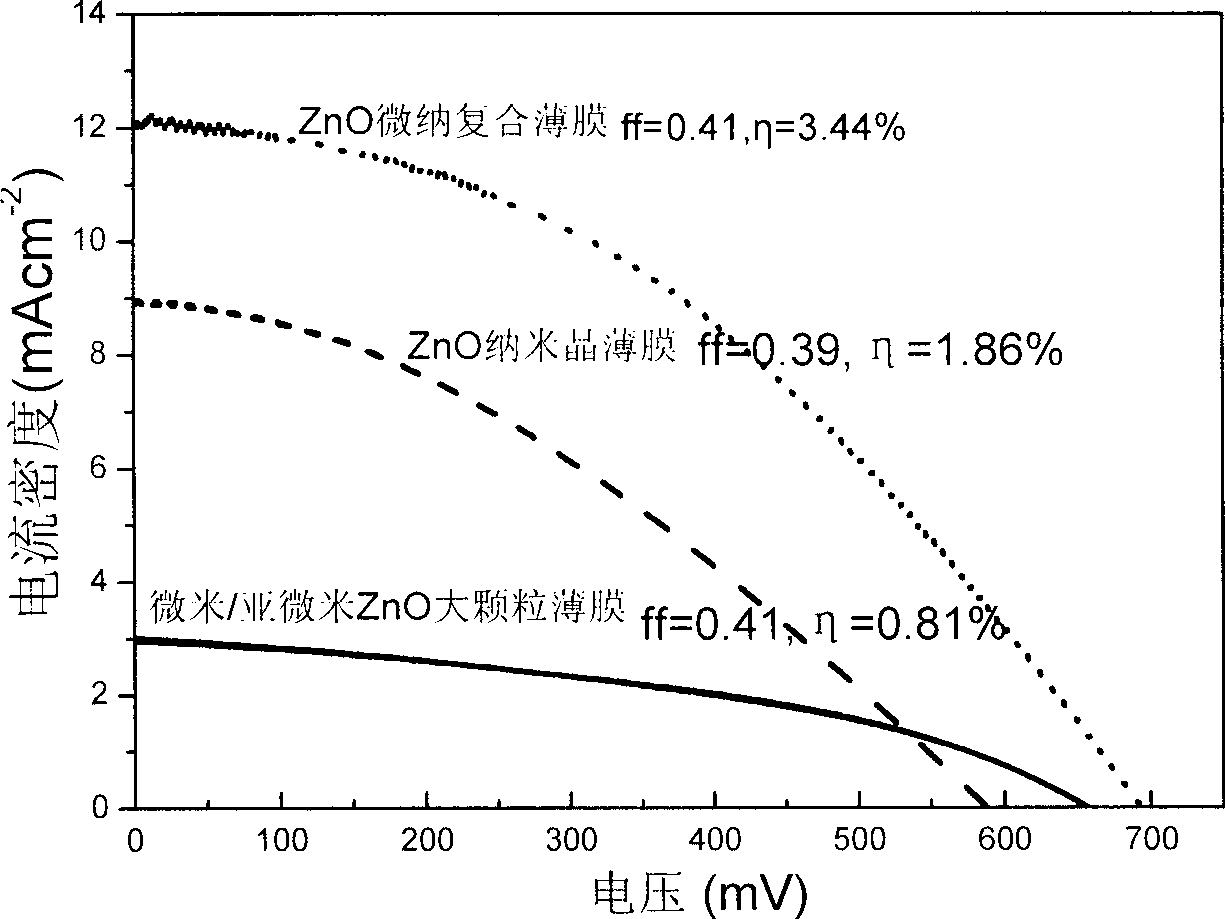

[0034] From image ...

Embodiment 3

[0036] 1) Preparation of ZnO nanocrystalline film:

[0037] 0.1g ZnO nanocrystals are added into 100ml of absolute ethanol to obtain a milky white solution after ultrasonic dispersion, and the ZnO nanocrystals film is prepared on the pretreated FTO conductive glass by the drop coating method, and then the ZnO nanocrystals film is placed in a muffle furnace at 250 ℃, roasted for 0.2h, cooled to room temperature to obtain ZnO nanocrystalline film;

[0038] 2) Preparation of ZnO micro-nano composite thin film

[0039] Dissolve flaky micron / submicron ZnO in absolute ethanol to obtain a solution with a concentration of 0.001g / mL, and prepare a layer of large particle micron / submicron ZnO film on the surface of ZnO nanocrystalline film by drop coating method, which will have a micron The ZnO double-layer film with nano-composite structure was placed in a muffle furnace and baked at 250°C for 0.2h, and then cooled naturally to room temperature to obtain a ZnO micro-nano composite fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com