Efficient reburning denitration mixed fuel made from solid wastes and preparation thereof

A solid waste and mixed fuel technology, applied in waste fuel, solid fuel, fuel, etc., can solve the problems of poor reburning effect, low volatile content of high-rank coal, limiting coal reburning and denitrification efficiency, etc., to reduce NOX pollution Emissions, saving effect of natural gas or pulverized coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

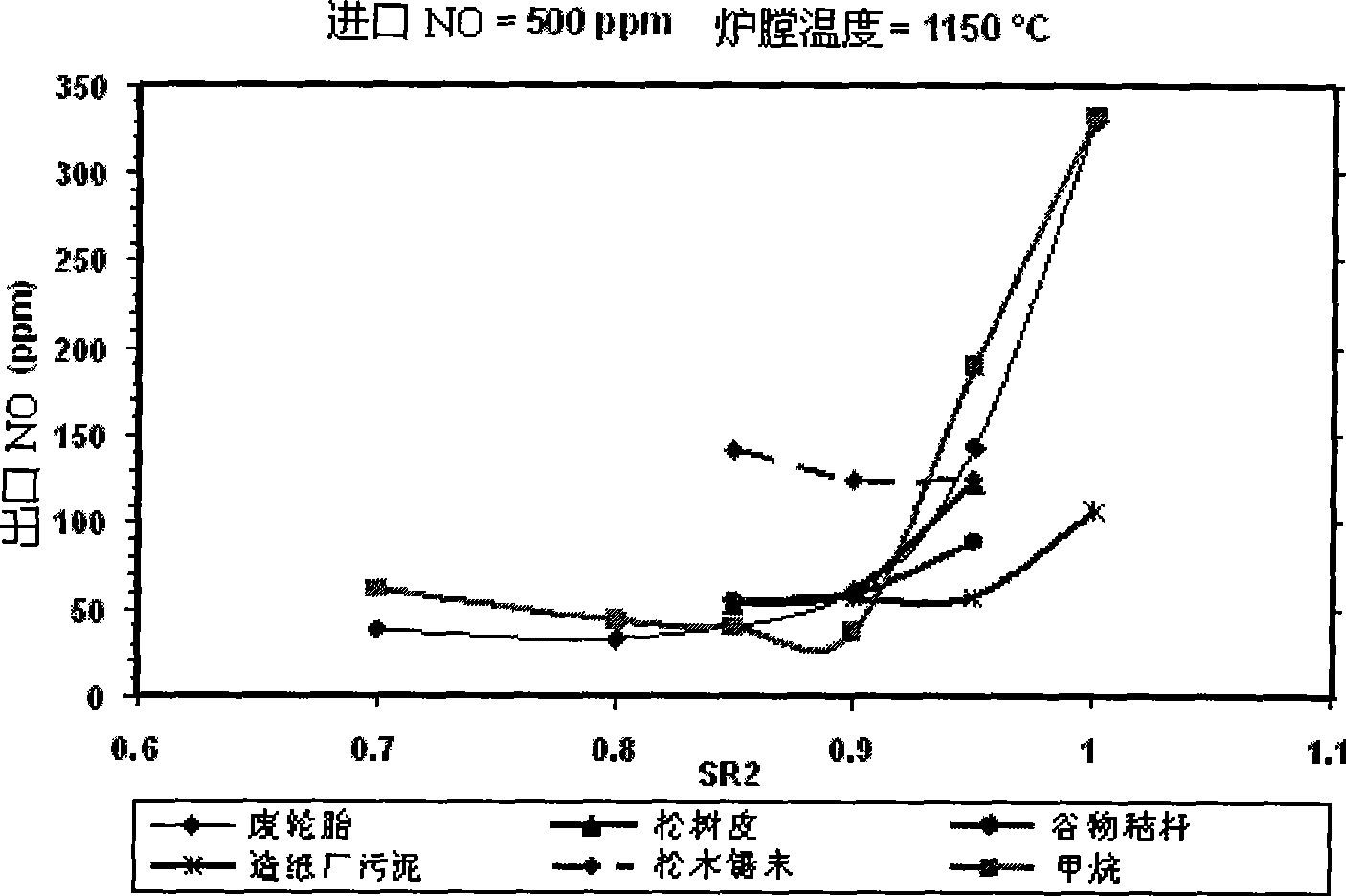

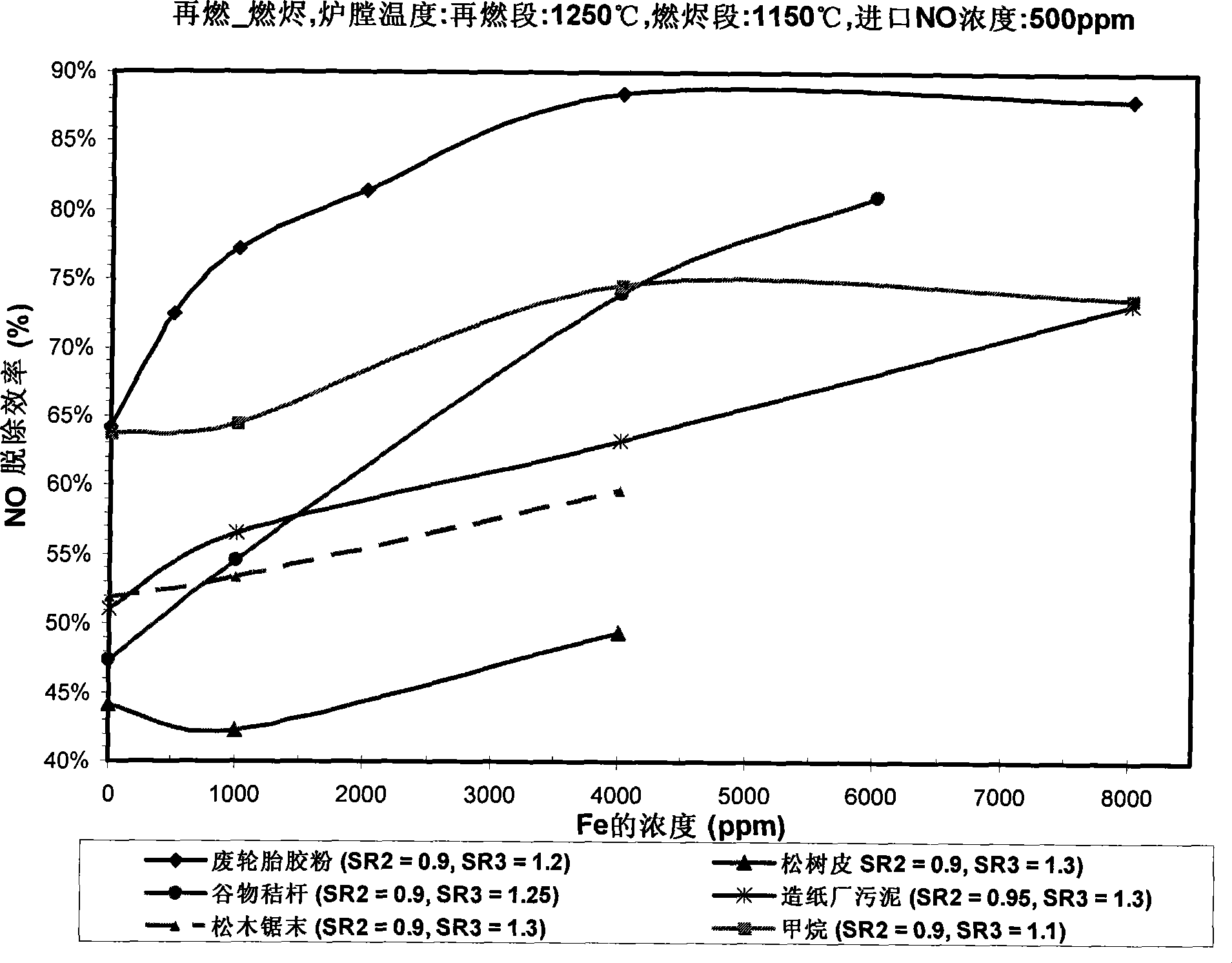

[0033] Such as figure 1As shown, the experimental results of denitrification characteristics of waste tire powder and biomass waste under typical reburning conditions and the comparison with the reburning results of natural gas under the same conditions. The results show that in the reburning process, waste tire powder and biomass waste have the same effect as natural gas on reburning and denitrification, and can effectively convert NO. The optimal stoichiometric ratio SR2 in the reburning section is 0.9-0.95.

Embodiment 2

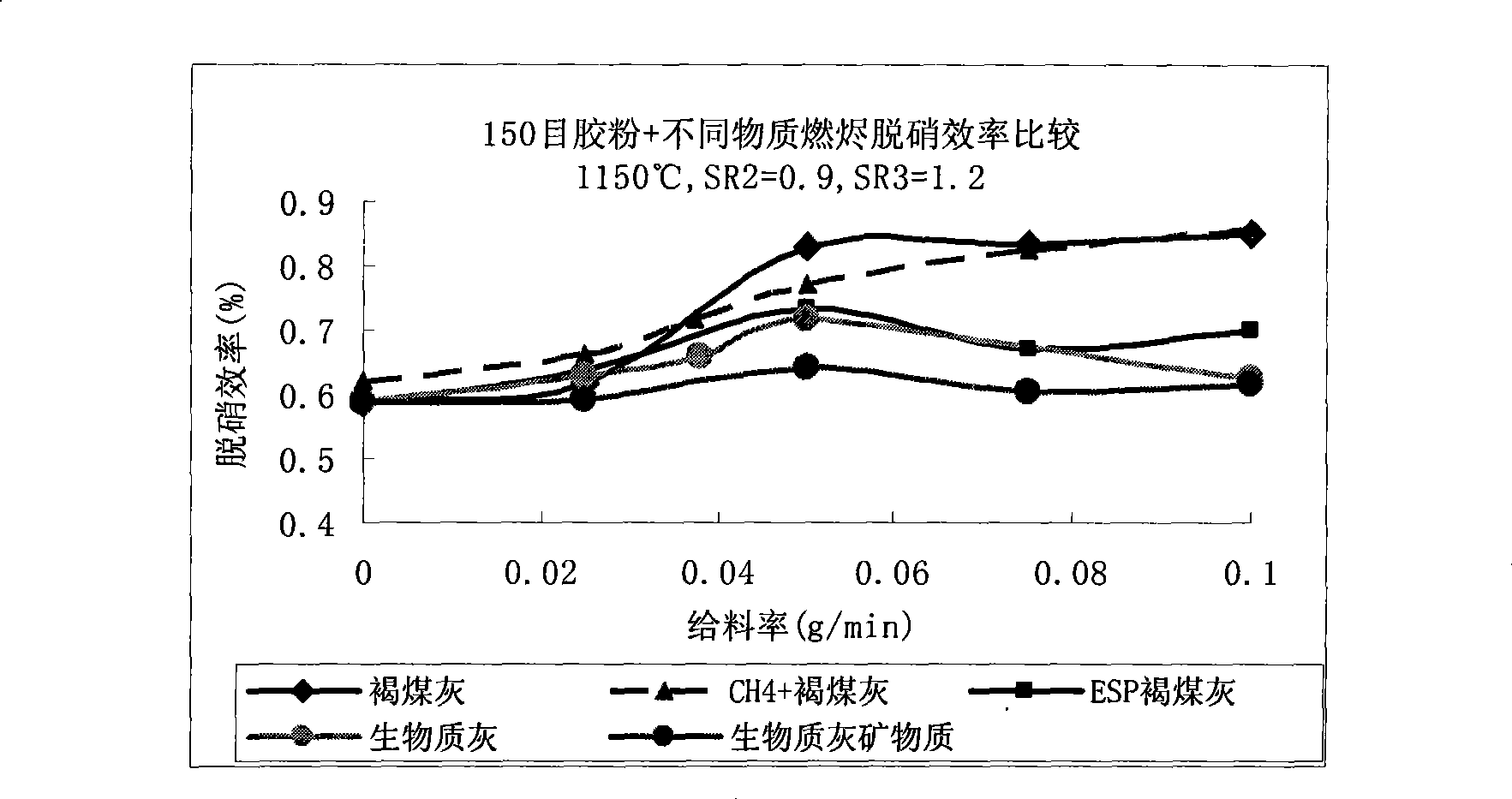

[0035] Such as figure 2 As shown, the denitrification efficiency of the mixed fuel 1 composed of waste tire rubber powder and lignite ash is compared with the denitrification efficiency of natural gas under the same conditions. The results show that in a typical two-stage denitrification process of reburning and embering, the denitrification efficiency of waste tire rubber powder and lignite ash collected by bag filter is as good as that of natural gas under the same conditions, exceeding 80%.

Embodiment 3

[0037] Such as figure 2 As shown, the denitrification efficiency of the mixed fuel 2 composed of waste tire rubber powder, biomass ash, biomass minerals, etc. is compared with the denitrification efficiency of natural gas under the same conditions. The results show that in a typical two-stage denitrification process of reburning and embering, when the feed rate of biomass ash is less than 0.05g / min, the denitrification efficiency of the mixed fuel composed of waste tire rubber powder and biomass ash is comparable to that of natural gas under the same conditions. The efficiency is as good as over 70%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com