Preparation of solid thermoluminescent dosemeter material

A thermoluminescence dose, solid technology, which is applied in the field of preparation of solid thermoluminescence dosimeter materials, can solve the problems of complex thermoluminescence peak shape, unfavorable dose signal test, reduced thermoluminescence sensitivity, etc. The properties are stable, the production cost is low, and it is convenient to test the effect of the signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

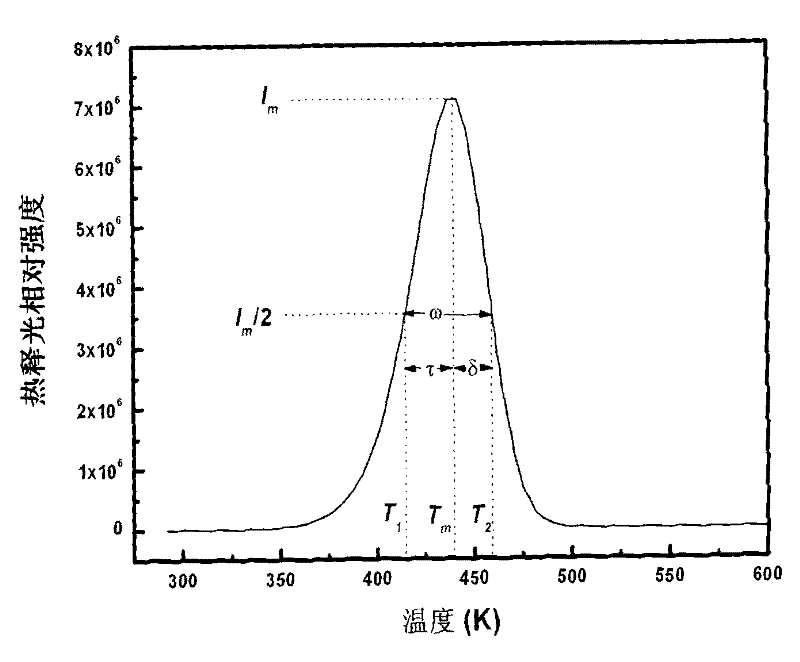

[0014] Raw material is SrHPO 4 (analytical pure), NH 4 h 2 PO 4 (analytical pure), Eu 2 o 3 (99.99%), Pr 6 o 11 (99.99%) The molar ratio between them is 1: 0.05: 0.02: 0.02. The raw materials are fully ground in a mortar, dried, placed in a corundum crucible, and then put into a large corundum crucible, filled with carbon Rods were put into a high-temperature furnace at 900°C for 3 hours, cooled to room temperature naturally, taken out and ground to obtain samples. The obtained product is a white powder, and its thermoluminescence peak is as figure 1 As shown, its luminescence curve is a single peak, and the peak temperature is at 439.5K.

Embodiment 2

[0016] Raw material is SrHPO 4 (analytical pure), NH 4 h 2 PO 4 (analytical pure), Eu 2 o 3 (99.99%), Pr 6 o 11 (99.99%) The molar ratio between them is 1:0.05:0.001:0.08. Grind the raw materials evenly in a mortar, dry them, put them into a corundum crucible, and then put them into a large corundum crucible, and fill them with carbon Rods were put into a high-temperature furnace for 3 hours at 1000°C and baked for 3 hours, cooled to room temperature naturally, taken out and ground to obtain samples. The obtained product is a white powder, and its thermoluminescence peak is as figure 1 As shown, its luminescence curve is a single peak, and the peak temperature is at 439.5K.

Embodiment 3

[0018] Raw material is SrHPO 4 (analytical pure), NH 4 h 2 PO 4 (analytical pure), Eu 2 o 3 (99.99%), Pr 6 o 11 (99.99%) The molar ratio between them is 1: 0.05: 0.005: 0.001. The raw materials are fully ground in a mortar, dried, placed in a corundum crucible, and then put into a large corundum crucible, filled with carbon Rods were put into a high-temperature furnace at 1200°C for 5 hours, cooled to room temperature naturally, taken out and ground to obtain samples. The obtained product is a white powder, and its thermoluminescence peak is as figure 1 As shown, its luminescence curve is a single peak, and the peak temperature is at 439.5K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com