Method for separating hemicellulose in high yield pulp waste liquor and use of hemicellulose separated thereby

A hemicellulose, high-yield technology, which is applied to the separation of hemicellulose in high-yield pulping waste liquid and the application field of hemicellulose, can solve the problems of complex structure, limited application and the like, and achieves simple process, Low-cost, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The pH value of the alkaline hydrogen peroxide mechanical pulp waste liquid (solid content is 2%) is adjusted to 3 with concentrated sulfuric acid with a concentration of 98%, and it is left to stand in a constant temperature water bath at 45°C for 30min, so that the lignin in the waste liquid Separate out, filter after lignin precipitation completely and obtain clear liquid, at room temperature with 6mol / L sodium hydroxide solution, the pH value of gained clear liquid is adjusted to 5, and add the dehydrated alcohol of 3 times of volume (to clear liquid), in Stand still at 55°C for 30 minutes to completely precipitate the hemicellulose, filter with suction, and obtain a hemicellulose filter cake, which becomes white powdery hemicellulose after being vacuum-dried at 55°C for 24 hours.

[0021] Cationic modification of hemicellulose: the hemicellulose separated in Example 1 is dispersed into a mixed solution of absolute ethanol and water (the volume ratio of ethanol:water...

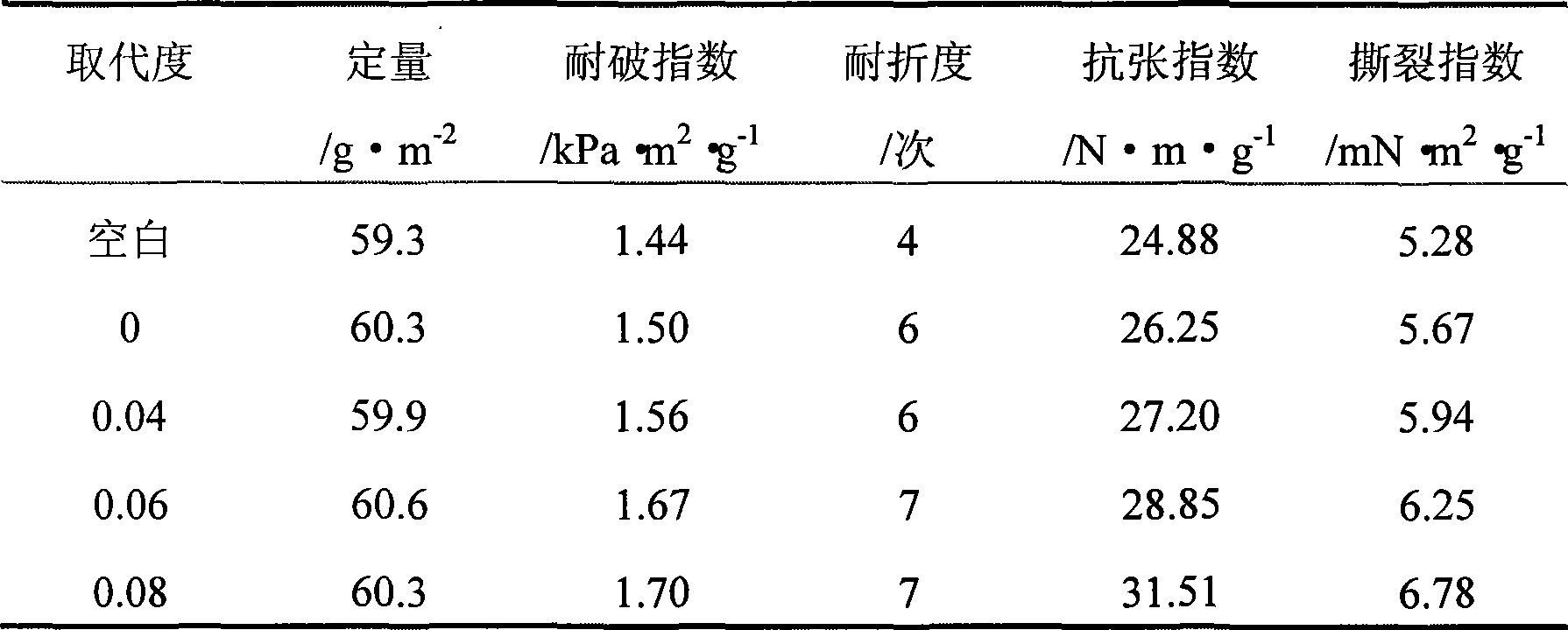

Embodiment 2

[0031] The application method of the cationic hemicellulose is the same as that of Example 1, except that the quaternary ammonium salt cationic hemicellulose pulp internal strengthening agent is added to the softwood pulp.

[0032] According to the national paper and cardboard physical property test method, the strength indexes of softwood pulp paper sheets are measured, see Table 2.

[0033] Table 2

[0034]

[0035] It can be seen from Table 2 that the quaternary ammonium salt cationic hemicellulose can significantly enhance the strength of softwood pulp paper.

Embodiment 3

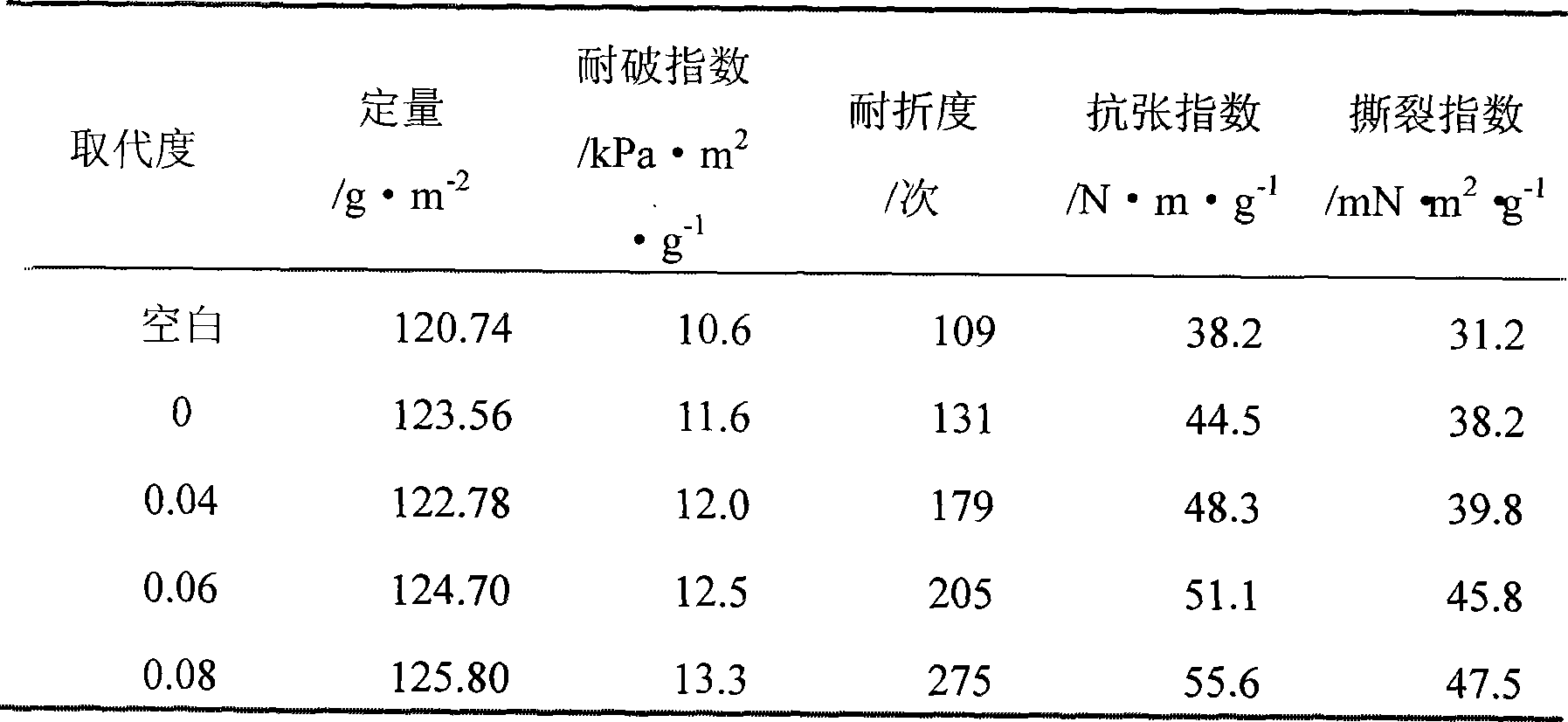

[0037] The application method of the cationic hemicellulose is the same as that in Example 1, except that a quaternary ammonium salt cationic hemicellulose pulp internal strengthening agent is added to the OCC waste paper pulp.

[0038] The strength indexes of OCC waste paper pulp sheets were measured according to the national paper and board physical property test method, see Table 3.

[0039] table 3

[0040]

[0041] It can be seen from Table 3 that the quaternary ammonium salt cationic hemicellulose can significantly enhance the strength of the OCC waste paper pulp sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com