Real-time monitoring device for light exposure in holographic grating production

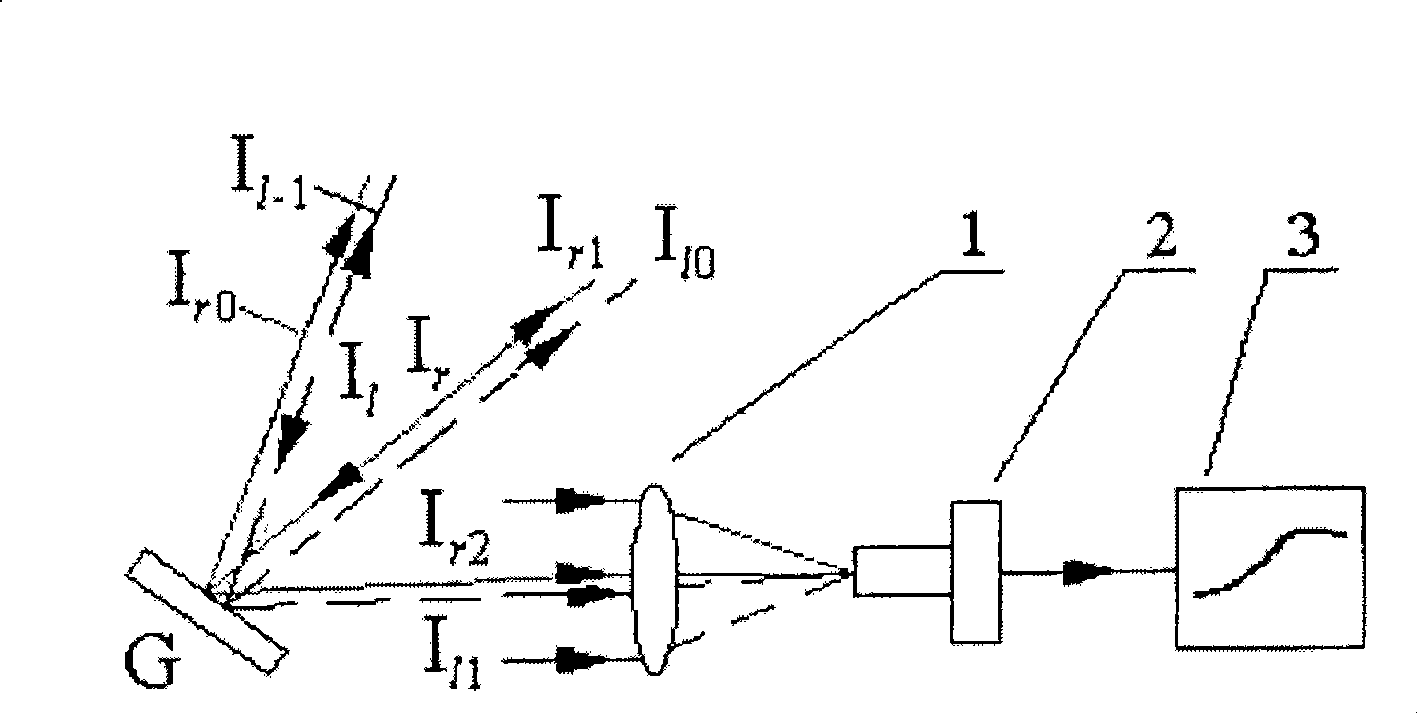

A real-time monitoring and holographic grating technology, applied in the field of spectroscopy, can solve the problems of inconvenient operation, difficult diffracted light, weak diffracted light energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

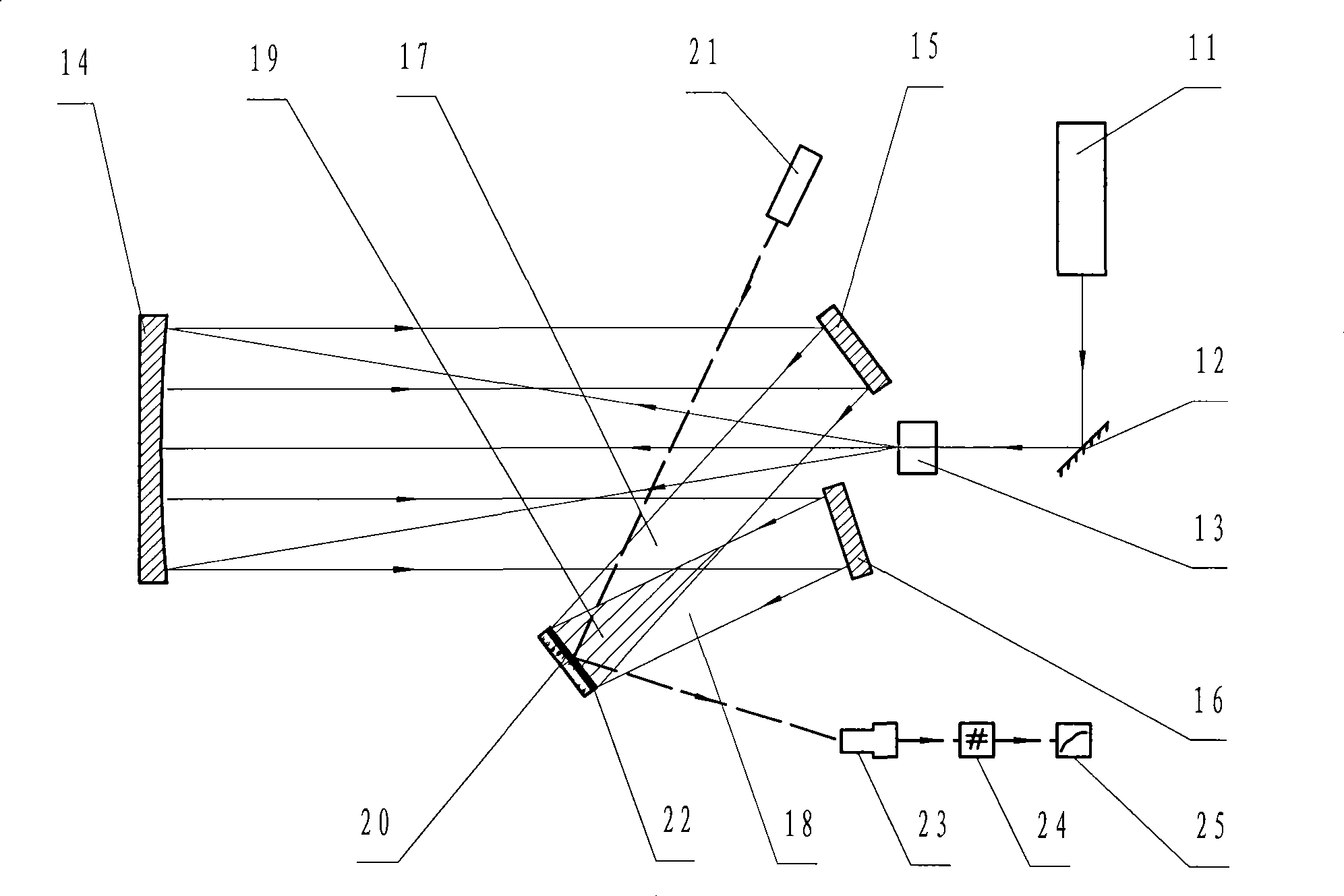

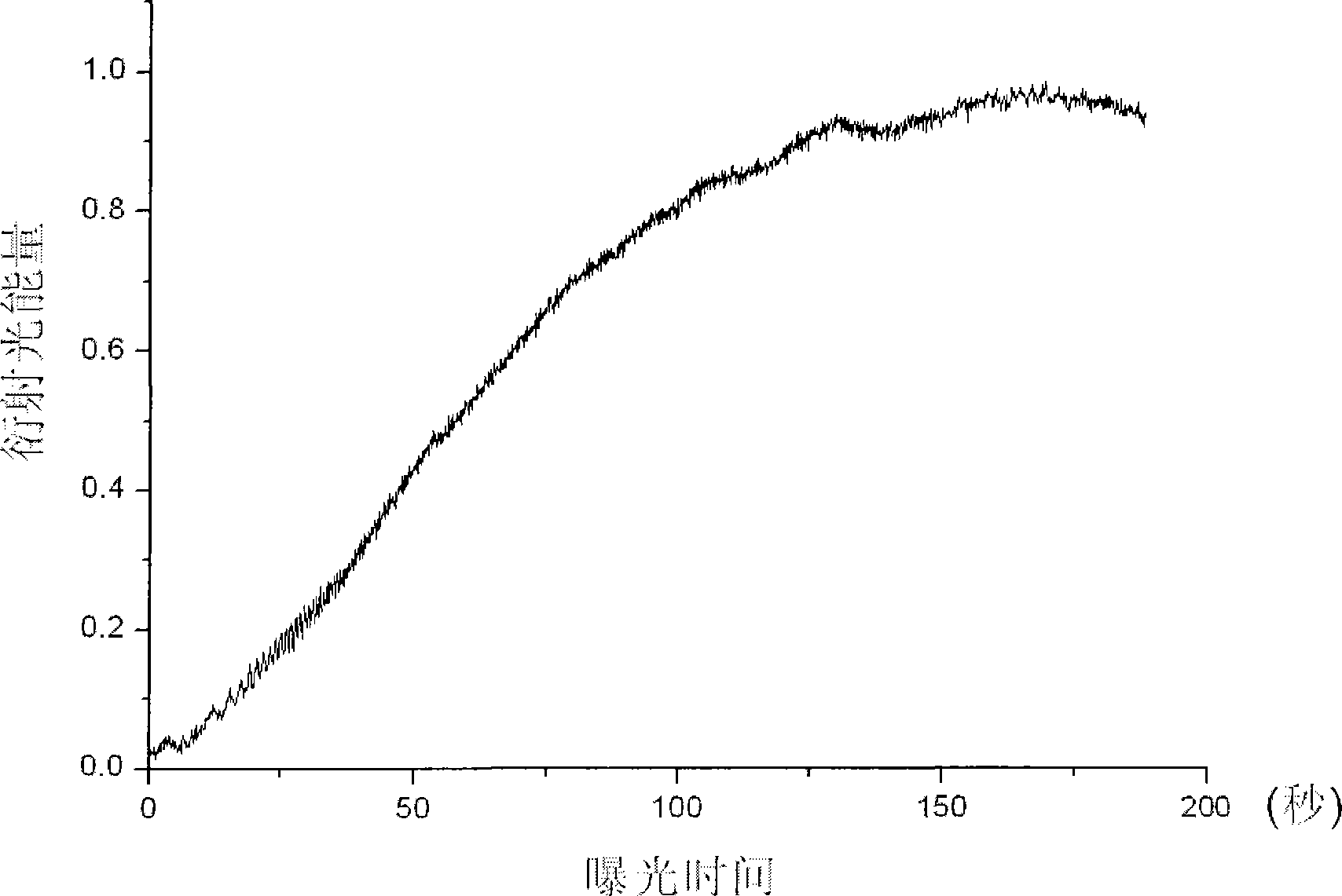

[0011] The invention presses figure 2 The technical solution shown is implemented, wherein the recording laser 11 uses a krypton ion laser with a wavelength of 413.1nm, the plane mirror 12 is a glass substrate aluminized mirror, and the spatial filter 13 is composed of a microscope objective lens and a pinhole, collimated and reflected The mirror 14 is made of K9 glass substrate with aluminized film, the diameter is ф320mm, the focal length f is 1200mm, the first adjustment mirror 15 and the second adjustment mirror 16 are glass substrate aluminized mirrors, the diameter is 160mm×110mm, the grating substrate is made 20 uses K9 optical glass. The photoresist coated on K9 optical glass is S1805 produced by Japan Shipley. The monitoring laser 21 uses a He-Ne laser with a wavelength of 632.8nm. The latent image grating 22 is made of photoresist. The photoelectric receiver 23 uses a photomultiplier tube, and the photomultiplier tube is only sensitive to the 632.8nm wavelength of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com