TFT-LCD pixel structure and method for manufacturing same

A technology of pixel structure and light-shielding structure, applied in semiconductor/solid-state device manufacturing, instruments, semiconductor devices, etc., can solve the problems of unable to block the light of the liquid crystal layer and reduce the picture quality, so as to improve the transfer characteristics, improve the picture quality, and reduce the leakage. Effect of current IOFF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

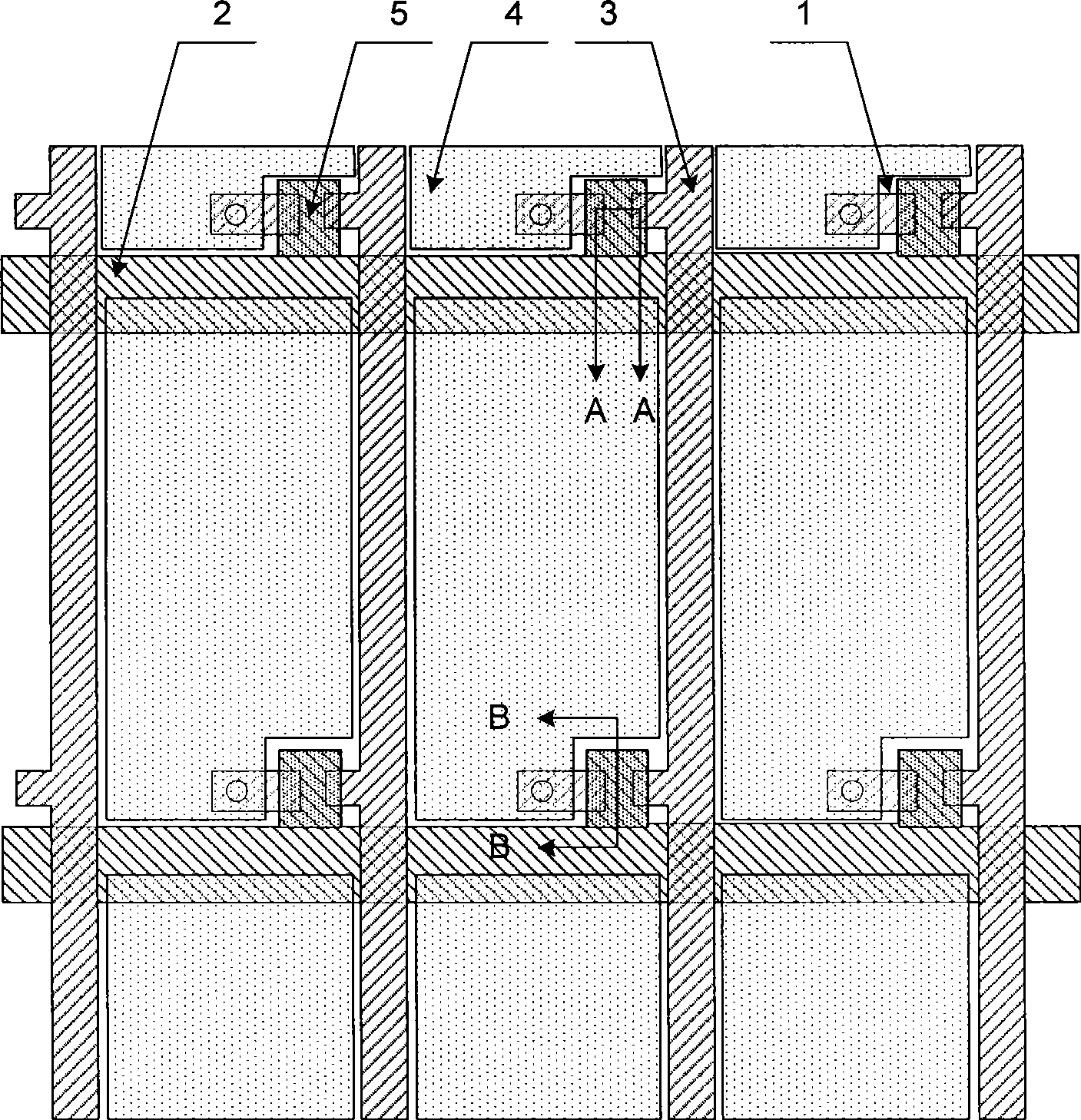

[0051] figure 1 It is a schematic diagram of the TFT-LCD pixel structure of the present invention. Such as figure 1 As shown, the TFT-LCD pixel structure includes a thin film transistor 1, a gate line 2, a data line 3, a pixel electrode 4 and a light-shielding structure layer 5, and the intersecting gate line 2 and data line 3 define several pixel regions, and the pixel electrode 4 Arranged in the pixel area, the thin film transistor 1 is used as a switching device, on which a channel area is formed, and the light-shielding structure layer 5 is arranged above the channel area of the thin film transistor 1, so as to cover the amorphous silicon layer in the thin film transistor 1 , thereby effectively reducing the influence of light from the liquid crystal layer on the amorphous silicon layer and reducing the leakage current I OFF , Improved transfer characteristics, improved picture quality.

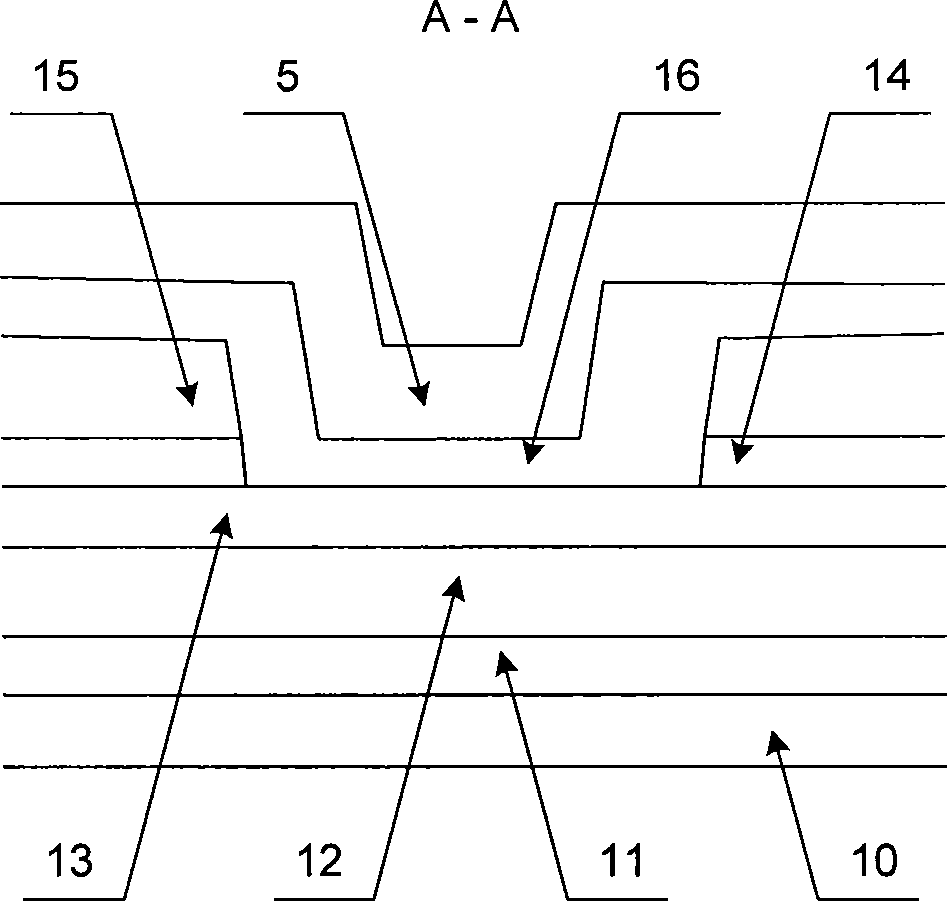

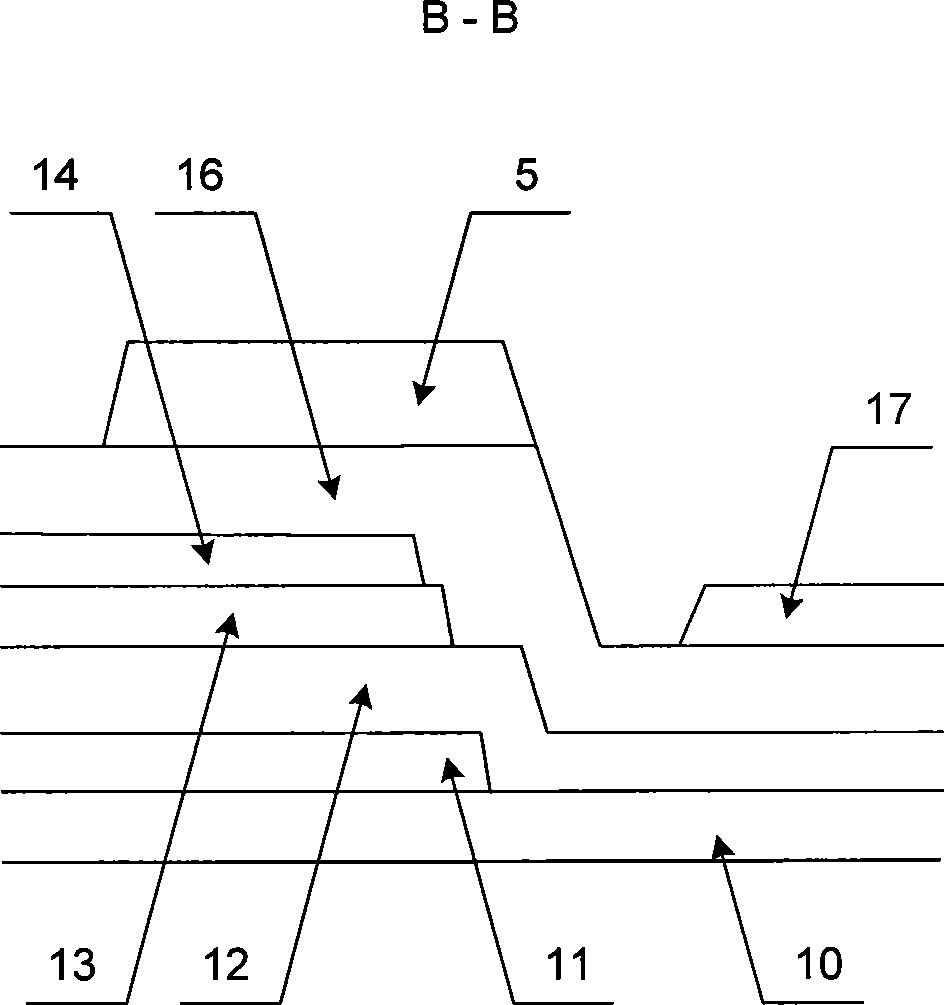

[0052] figure 2 for figure 1 The sectional view of A-A direction in the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com