Fixed shape phase-change material based on tetradecane and method for producing the same

A technology of shape-setting phase change material and tetradecane, applied in the field of materials, can solve problems such as inconvenience of direct application, and achieve the effect of convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the fixed-shape phase-change material involved in the present invention is:

[0026] (1) Dry PE and thermoplastic elastomer at 60-80°C for 6-12 hours, then cool to room temperature. Mix the two together with C14 and cross-linking agent in proportion, and place them at room temperature for 24 hours.

[0027] (2) Reactively extrude the mixing system of (1) in a screw extruder. The temperature of each section of the extruder from the feeding port, the barrel to the head is 130-150°C, 140-150°C and 130-150°C respectively.

[0028] (3) Extruded profiles (including but not limited to plates) are cooled after being coated with EVOH (ethylene-vinyl alcohol copolymer) film.

[0029] According to different material formulations, the present invention can prepare hard boards and soft coils respectively to meet different application requirements.

Embodiment 1

[0031] (1) Dry 40kg of PE and 27kg of SBS at 80°C for 6 hours, then cool to room temperature. And mix well with 30kg of C14 and 3kg of BPO, and leave it at room temperature for 24 hours.

[0032] (2) Extrude the mixture of (1) in a twin-screw extruder. The temperature of each section of the extruder is respectively: feeding port 150°C, barrel 150°C, head 150°C.

[0033] (3) Extrude the surface of the plate to coat the EVOH film and then cool to obtain a hard plate-shaped phase-change material.

Embodiment 2

[0035] (1) Dry 20 kg of SIS at 60°C for 8 hours, then cool to room temperature. And mix evenly with 80 kg of C14, leave it at room temperature for 24 hours.

[0036] (2) Extrude the mixture of (1) in a twin-screw extruder. The temperature of each section of the extruder is respectively: feeding port 130°C, barrel 150°C, head 130°C.

[0037] (3) Coating EVOH film on the surface of the extruded plate and cooling to obtain a soft shape-setting phase change material coil.

PUM

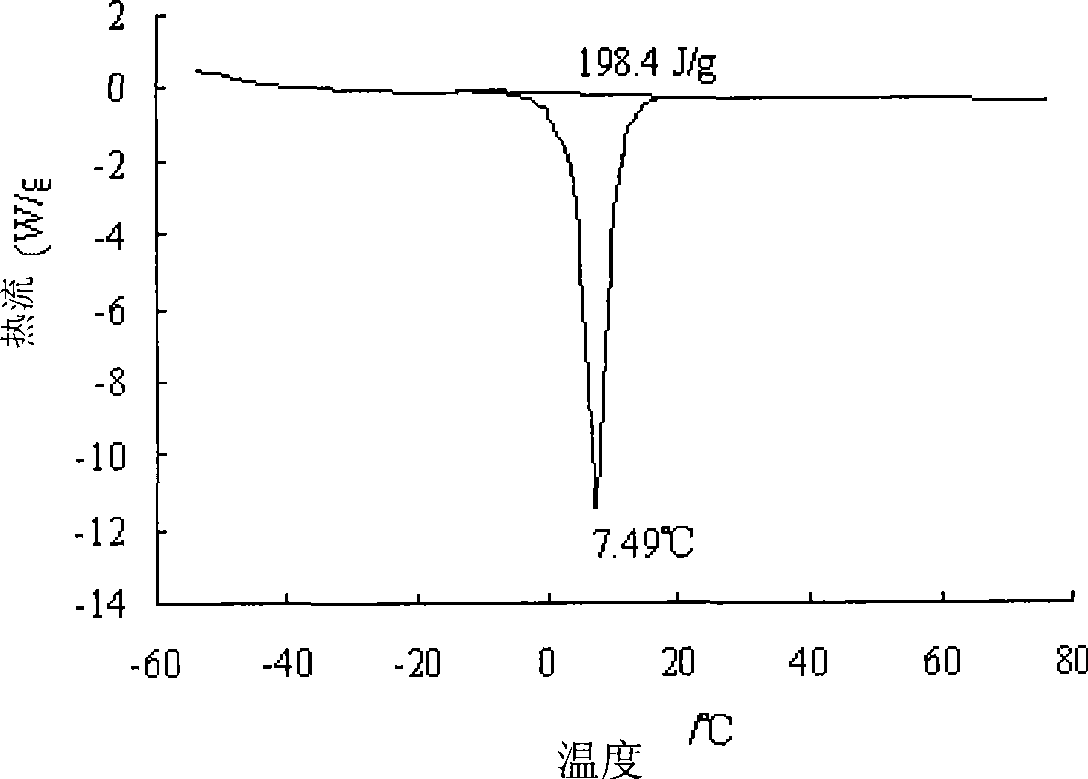

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com