Manufacturing method for integrated schottky diode

A technology of Schottky diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve the problem of uneven protection ring of integrated Schottky tubes, low and uniform breakdown voltage of integrated Schottky tubes Poor performance and other problems, to achieve the effect of uniform protection ring, easy repair interface layer, high breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

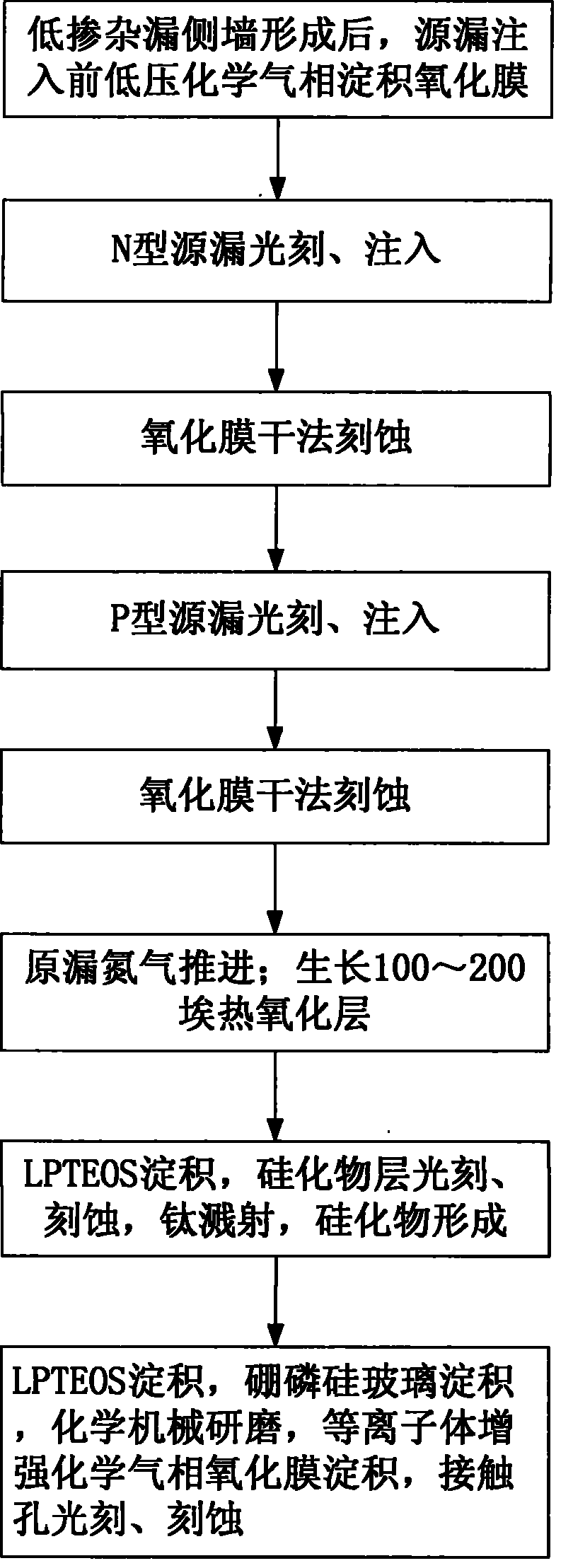

[0034] An embodiment of the integrated Schottky diode manufacturing method of the present invention is shown in Figure 3, comprises the following steps:

[0035] (1) Low-pressure chemical vapor deposition oxide film (LPTEOS) after the low-doped drain sidewall (LDD) is formed;

[0036] (2) N-type source-drain (NSD) lithography and implantation;

[0037] (3) LPTEOS dry etching;

[0038] (4) P-type source-drain (PSD) lithography and implantation;

[0039] (5) LPTEOS dry etching;

[0040] (6) Source-drain (SD) nitrogen propulsion; growth of 100-200 angstrom thermal oxide layer;

[0041] (7) 500 Angstrom LPTEOS deposition, silicide layer (SB) photolithography, etching, titanium sputtering, silicide (silicide) formation;

[0042] (8) LPTEOS deposition, borophosphosilicate glass deposition (BPSG), chemical mechanical polishing (CMP), plasma enhanced chemical vapor deposition oxide film (PETEOS) deposition, contact hole (CT) lithography and etching.

[0043] The difference betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com