Conductivity composite material

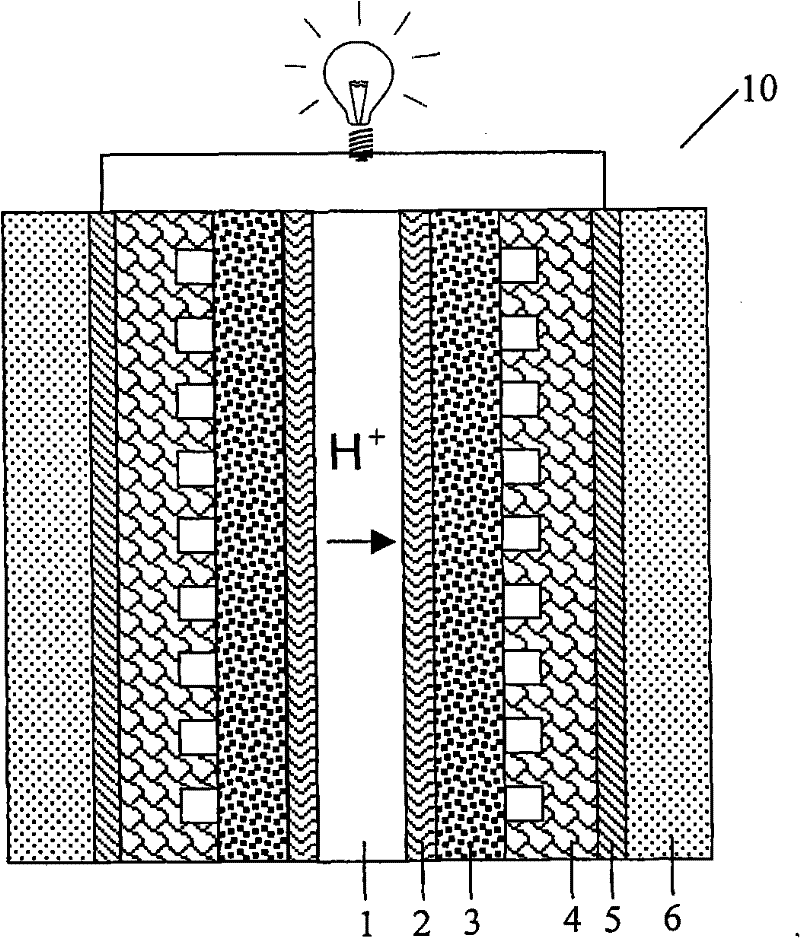

A technology of conductive composite materials and conductive fillers, applied in the direction of conductive coatings, conductive adhesives, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of bending and insufficient conductivity, and achieve high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 : Sheet made of VTBN-styrene-divinylbenzene copolymer and carbon material containing expanded graphite

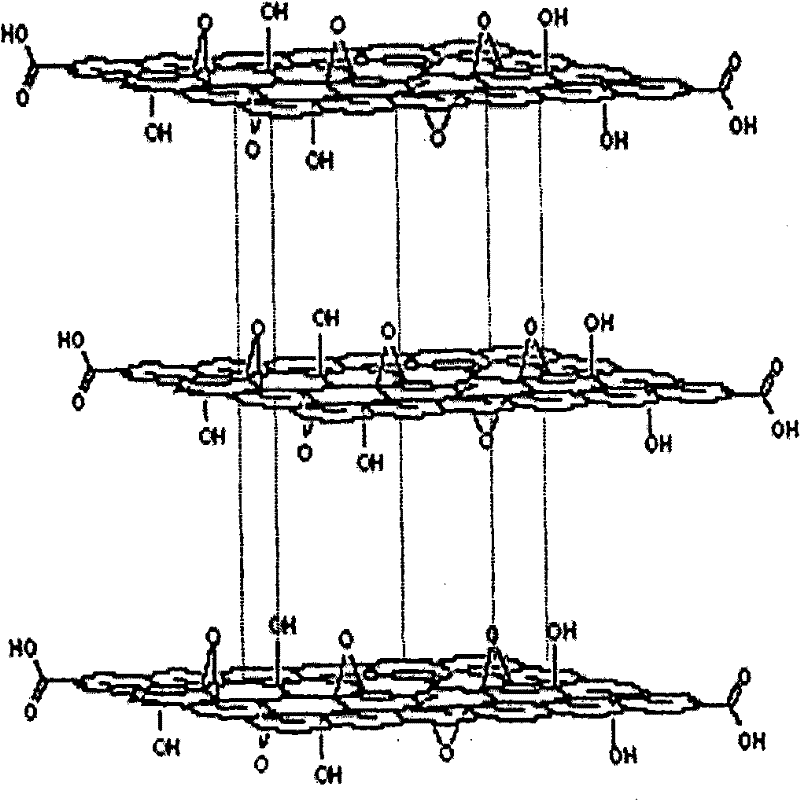

[0050] Preparation of expanded graphite:

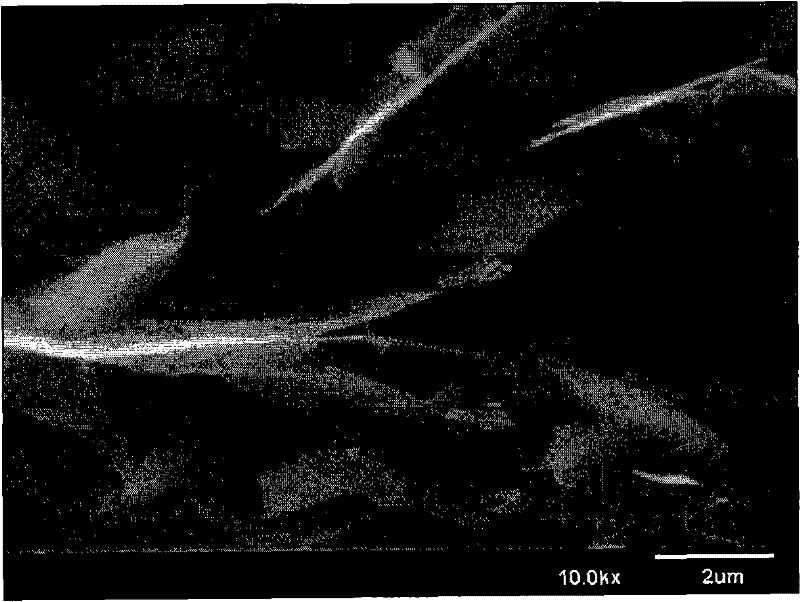

[0051] Put 200g of purchased graphite oxide into a 3-liter stainless steel tank, quickly put it into a high-temperature furnace at 1000°C, and heat it under air for 60 seconds to make it expand. After the expansion is complete, take it out and cool it at room temperature for later use.

[0052] Preparation of bipolar plates:

[0053] VTBN-styrene-divinylbenzene copolymer is kneaded with carbon material powder to form a homogeneous molding mixture (BMC, bulk molding compound), wherein the content of the carbon material (graphite powder+expanded graphite+carbon fiber) is 75% by weight. The free radical initiator is tert-butyl peroxybenzoate (TBPB), the solvent is styrene, and the release agent is fluorine wax. The selection principles of the above materials are not only suitable for the properties of the bip...

Embodiment 2

[0077] Example 2 : Plate made of VTBN-styrene copolymer and carbon material

[0078] VTBN-styrene copolymer is kneaded with carbon material to form a uniform molding mixture (BMC, bulk molding compound), wherein the content of carbon material (graphite powder + carbon fiber) is 75% by weight. The free radical initiator is tert-butyl peroxybenzoate (TBPB), the solvent is styrene, and the release agent is fluorine wax. The selection principles of the above materials are not only suitable for the properties of the bipolar plate, but also the reasonable price is also a consideration; the ratio of various materials is shown in Table 3.

[0079] Table three

[0080] Material

Example 2

Comparative example 2

Comparative example 3

Graphite powder + carbon fiber

75%

75%

75%

VTBN

12.5%

Rubber reinforced vinyl ester based resin

15%

vinyl ester resin

15%

12.5%

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com