Nano Al2O3 film encapsulated carbon-aluminum spinelle refractory castable and preparation method thereof

A technology of aluminum spinel and film wrapping, applied in the field of refractory materials, can solve the problems of deformation service life of ladle furnace shell, thermodynamic instability, increase of heat loss rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

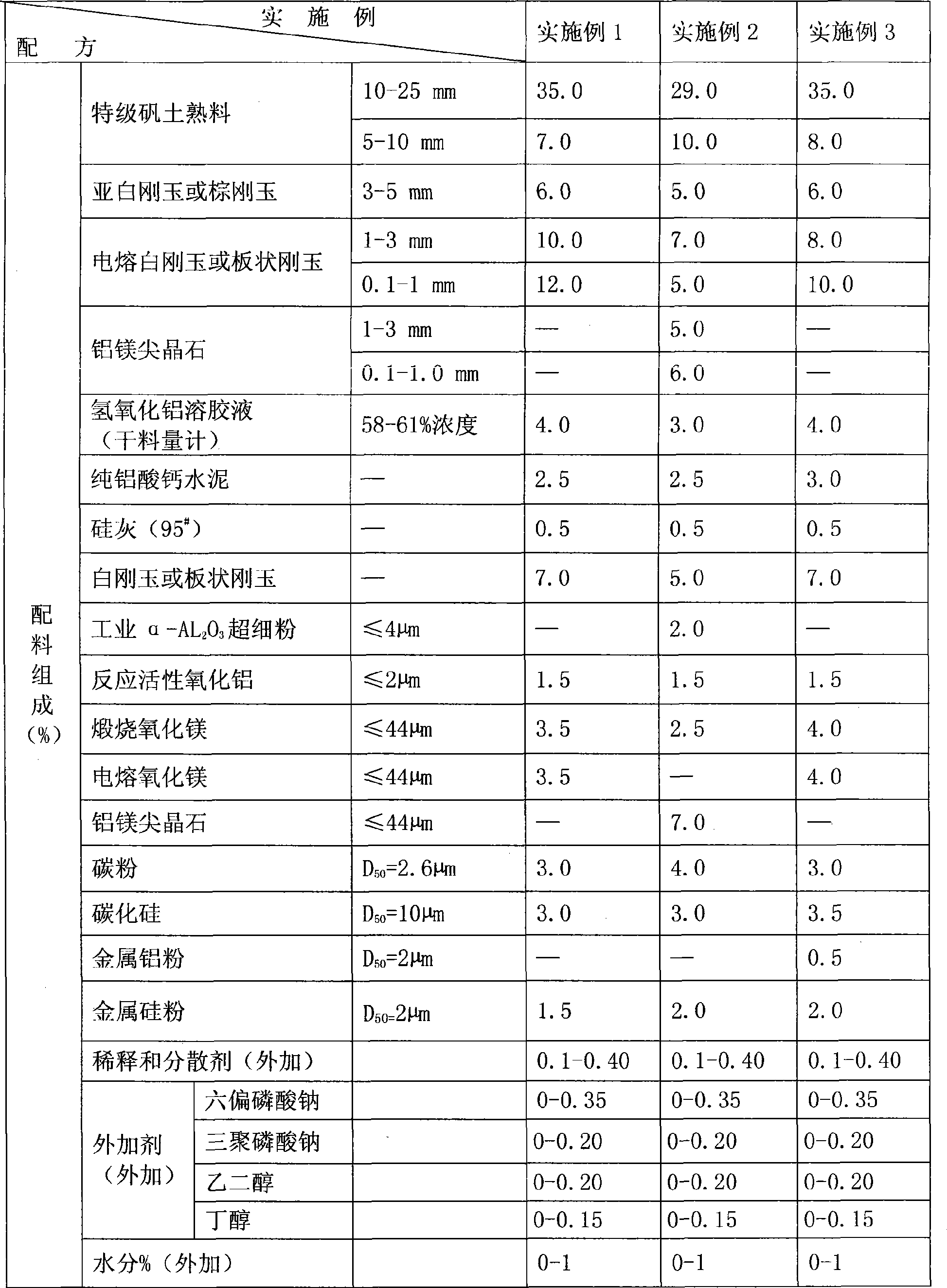

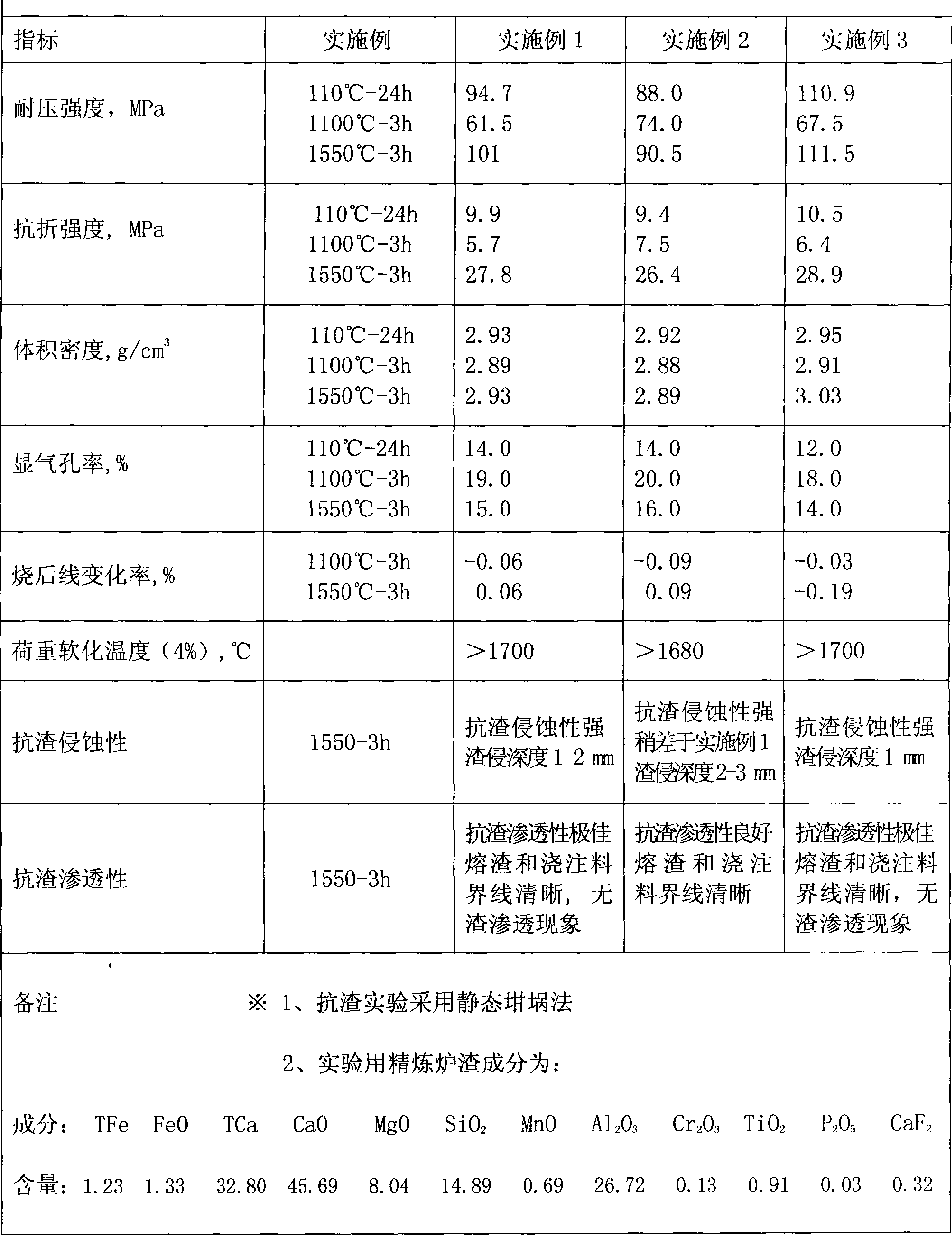

Embodiment 1

[0030] Listed in the reaction synthesis nanometer AL of table 1 embodiment 1 according to the present invention 2 o 3 The film-wrapped carbon-aluminum spinel castable formula, the mixture is added to the forced mixer for 1-2 minutes of dry mixing, and then the nano-carbon with a concentration of 58-61% is processed by high-speed impact stirring for solification and dispersion - Aluminum hydroxide composite sol suspension is directly added to the mixture, and then wet mixed for 5 minutes. During the mixing process, 0-1% of water is added according to the actual water demand of the mixture to make the reaction synthesis method of the present invention nano-AL 2 o 3 Film-wrapped carbon-aluminum spinel castables. The main technical performance indicators of the castable in this example are listed in Table 2. Its biggest features are: dense structure, low porosity, high compressive and flexural strength, and excellent slag erosion resistance and slag penetration resistance, suit...

Embodiment 2

[0032]According to the present invention listed in Table 1 Example 2 pre-synthesized carbon-aluminum spinel castable formula, add the mixture and dry mix it in a forced mixer for 1-2 minutes, then carry out solization and dispersion treatment through high-speed impact stirring The carbon-aluminum hydroxide composite sol suspension with a concentration of 58-61% is directly added to the mixture, and then wet mixed for 5 minutes. During the mixing process, 0-1% of water is added according to the actual moisture content of the mixture to make the present invention Pre-synthesized nano-AL 2 o 3 Film-wrapped carbon-aluminum spinel refractory castable. The main technical performance indicators of the castable in this example are listed in Table 2. Its biggest feature is its excellent thermal shock resistance and high temperature structural stability, and it is not easy to crack and peel off in actual use. It is suitable for use at the bottom of the LF refining furnace. .

Embodiment 3

[0034] Example 3 Nano AL listed in Table 1 according to the present invention 2 o 3 The film-wrapped carbon-aluminum spinel castable formula is mixed and stirred by a mixer, and vibrated by a vibrating table or a vibrating rod to form a large prefabricated component with a size of 1120 / 1200×670×460 cm and a unit weight of 1100kg. Air curing 24 hours, baking in an electric heating oven, baking temperature: 280 ° C, baking time: 120 hours. Then the large prefabricated components are placed in the impact area of the refining ladle, and then the bottom of the refining ladle is integrally poured. The biggest feature of using prefabricated large-scale components in the impact area is that it has strong impact resistance to molten steel and significantly improved service life. Compared with the on-site integral pouring structure in the impact area, its service life can be increased by more than 50-80%. In addition, it is also Advantageous conditions are provided for the integral ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com