Process for treating revolving furnace flue gas dedusting water from steel mill by low hardness method

A converter flue gas and low hardness technology is applied in the field of water treatment in steelmaking plants, which can solve the problems of substandard flue gas emission, reducing water flow, affecting dust removal efficiency and system balance, etc., and achieving low equipment failure rate and production shutdown maintenance rate. , the effect of reducing the amount of occurrence and emission, and improving the efficiency of resource use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

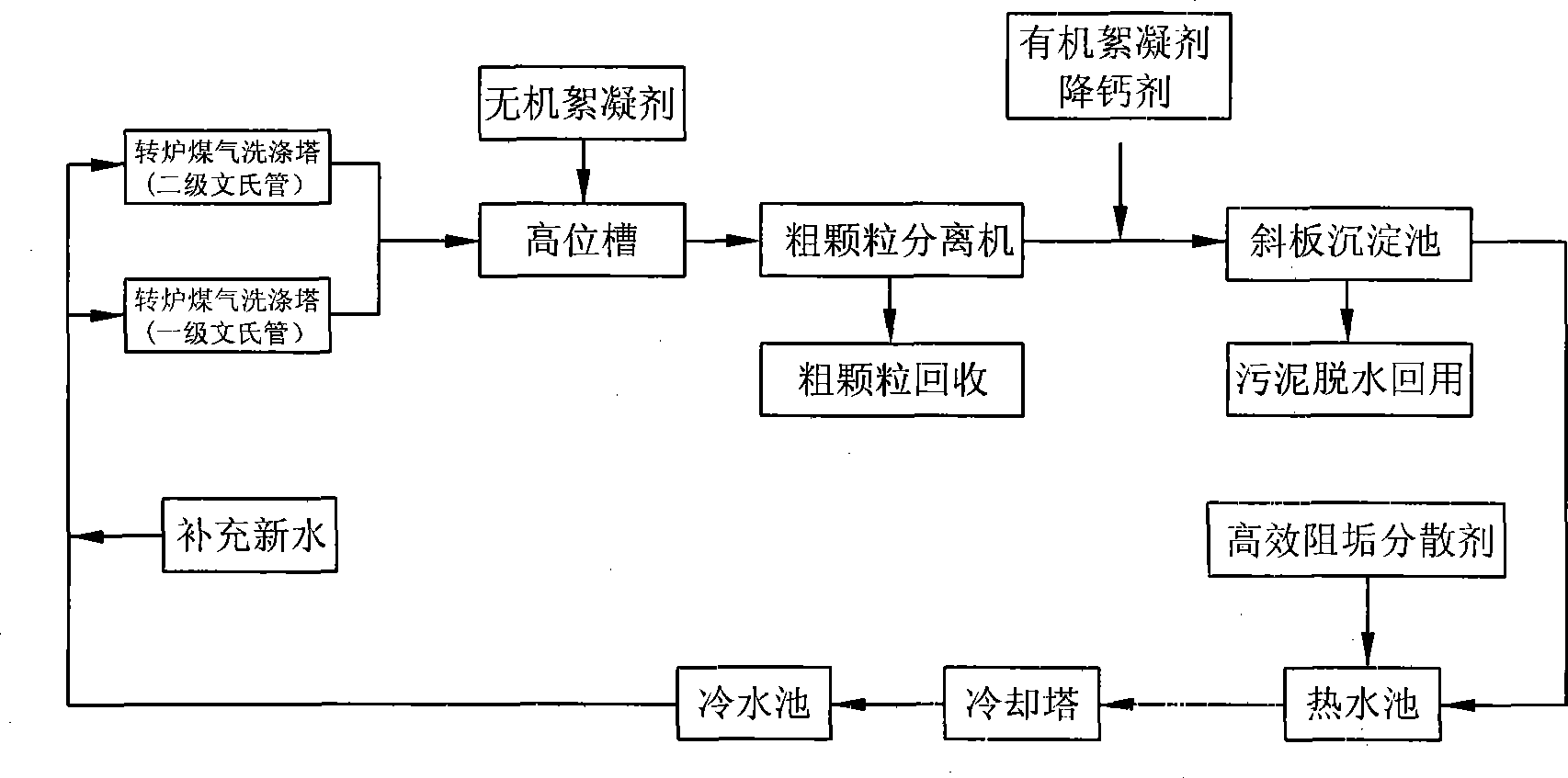

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0032] see image 3 , a low-hardness method for treating converter flue gas dedusting water in steel mills. The wastewater from the converter gas scrubber enters the head tank, and an inorganic coagulant is added to the water body in the head tank. The main content of the inorganic coagulant is Components and their weight percent content are: Fe 2 o 3 : 22~28%, Al 2 o 3: 3 to 5%; pass the outlet of the high level tank through the coarse particle separator, and recycle the coarse particles; enter the effluent of the coarse particle separator into the inclined plate sedimentation tank, and then add organic flocculant and reducing agent to the water body in the inclined plate sedimentation tank Calcium agent, the main components of the organic flocculant and its weight percentage content are: polyacrylamide: 50-90%, its molecular weight is greater than 12 million...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com