Scale and corrosion inhibitor formula for high concentration multiple operation of recirculated cooling water system and method of use thereof

A technology of circulating cooling water and scale and corrosion inhibitors, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the hazards of scale adhesion, affect production, increase energy consumption, etc. problems, to achieve the effect of solving hazards, improving recycling rate, reducing external drainage and replenishing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

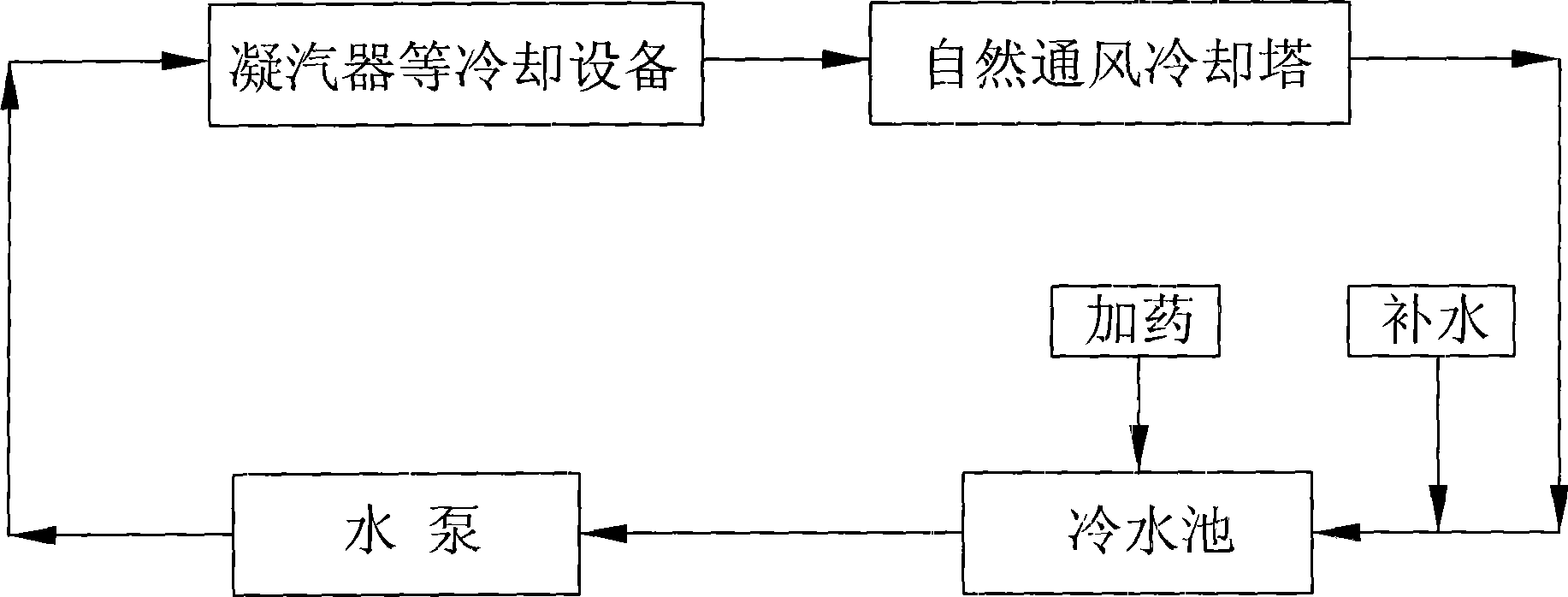

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0023] A scale and corrosion inhibitor formula for high concentration ratio operation of a circulating cooling water system, the components in the formula and their weight percentage content are: 2-phosphonic acid butane-1,2,4-tricarboxylic acid (PBTCA) is 15.0, hydroxyethylidene diphosphonic acid (HEDP) is 8.0, ZnSO 4 .7H 2 O is 12.0, benzotriazole (BTA): 1.5, (NaPO 3 ) 6 Sodium hexametaphosphate is 3.0, H 2 SO 4 is 2.0, acrylic acid / 2-acrylamido-2-methylpropanesulfonic acid copolymer (AA / AMPS) is 30.0, and the rest are H 2 O.

[0024] The production method of scale and corrosion inhibitor formula for high concentration multiple operation of circulating cooling water system:

[0025] 1. Production preparation: According to the requirements of the production schedule, calculate the weight of each component material according to the proportion of scale and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com