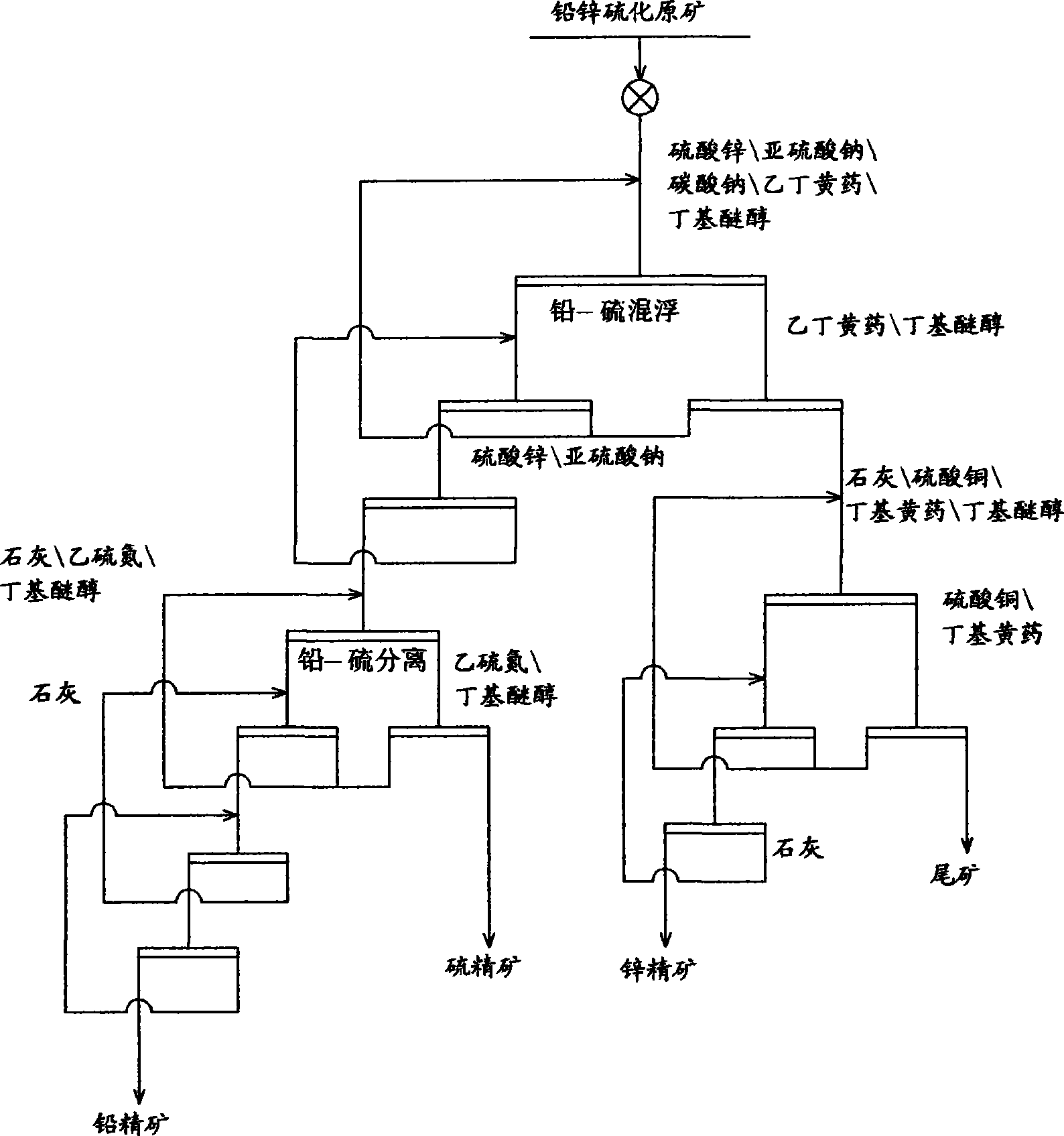

New flotation technique of lead zinc sulphur ore

A sulfide ore and new process technology, applied in flotation, solid separation, etc., can solve the problems of high cost, poor concentrate quality, high tailing, etc., achieve high recovery rate, reduce the mutual content of concentrate, and have little impact on separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A new process for flotation of lead-zinc sulfide ore, the following process steps are adopted:

[0018] ①. Use a wet ball mill for ball milling. Add 400g / t of zinc sulfate, 210g / t of sodium sulfite, and 500g / t of sodium carbonate to the raw lead-zinc sulfide ore of the ball mill to calculate the beneficiation agent according to the weight of the reactants. When -200 mesh accounts for 68%, the grinding product does not go through desliming, directly adds 50g / t of ethyl butylated xanthate, 50g / t of butyl ether alcohol into the lead-sulfur mixed flotation tank for flotation, and the pH value of the flotation medium Control is 7.5;

[0019] ②. Add 190g / t of zinc sulfate and 200g / t of sodium sulfite to the target minerals flotation in step ① according to the weight of the reactants in the current step, and add 190g / t of sodium sulfite into a beneficiation, and take the foam product to obtain the mixed concentrate of lead and sulfur;

[0020] ③. Add lime 2400g / t to the flota...

Embodiment 2

[0027] A new process for flotation of lead-zinc sulfide ore, the following process steps are adopted:

[0028] ①. Use a wet ball mill for ball milling. Add 380g / t of zinc sulfate, 200g / t of sodium sulfite, and 520g / t of sodium carbonate to the lead-zinc sulfide raw ore of the ball mill to calculate the beneficiation agent according to the weight of the reactants. When -200 mesh accounts for 75%, the grinding product does not go through desliming, directly adds 40g / t of ethyl butylated xanthate, 70g / t of butyl ether alcohol into the flotation of the lead-sulfur mixed flotation tank, and the pH value of the flotation medium Control is 8;

[0029] ②. Add 210g / t of zinc sulfate and 190g / t of sodium sulfite to the target minerals flotation in step ① according to the weight of the reactants in the current step, and then add 210g / t of sodium sulfite into a beneficiation, and take the foam product to obtain a mixed concentrate of lead and sulfur;

[0030] ③. Add lime 2500g / t to the f...

Embodiment 3

[0037] A new process for flotation of lead-zinc sulfide ore, the following process steps are adopted:

[0038] ①. Use a wet ball mill for ball milling. Add 410g / t of zinc sulfate, 190g / t of sodium sulfite, and 480g / t of sodium carbonate to the raw lead-zinc sulfide ore of the ball mill to calculate the beneficiation agent according to the weight of the reactants. When -200 mesh accounts for 70%, the grinding product does not go through desliming, directly adds 60g / t of ethyl butyrate xanthate, 60g / t of butyl ether alcohol into the flotation of the lead-sulfur mixed flotation tank, and the pH value of the flotation medium Control is 8.5;

[0039] ②. Add 200g / t of zinc sulfate and 210g / t of sodium sulfite to the target minerals flotation in step ① according to the weight of the reactants in the current step, and add 200g / t of sodium sulfite into a beneficiation, and take the foam product to obtain the mixed concentrate of lead and sulfur;

[0040] ③. Add lime 2600g / t to the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com