Method and apparatuses for pretreating sewage plant excess sludge by microwave method and producing hydrogen by fermentation

A technology for excess sludge and pretreatment, applied in the direction of fermentation, etc., can solve the problems of increased production costs, low hydrogen purity, high manufacturing requirements, etc., and achieve the effects of cost savings, increased hydrogen purity, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

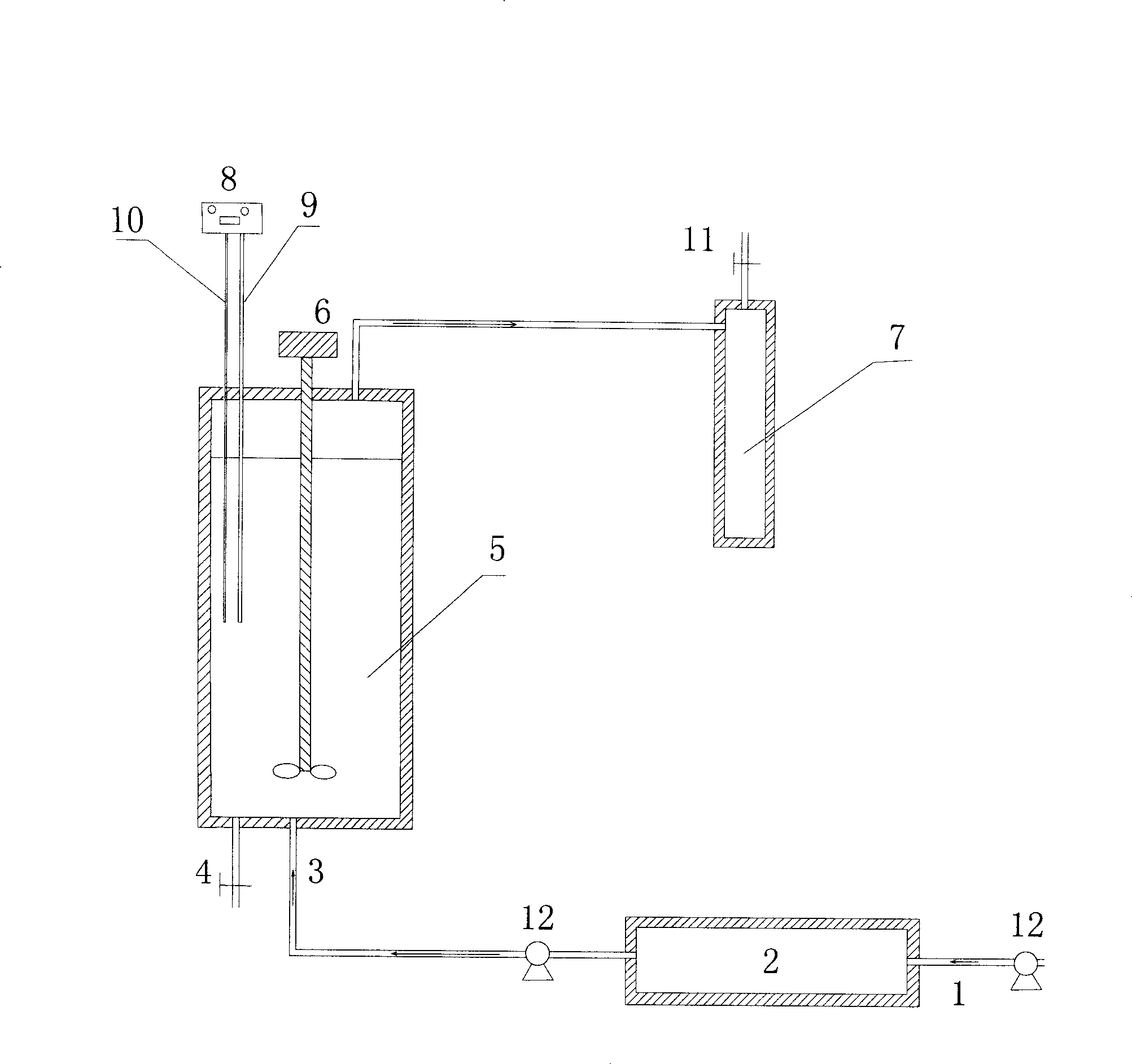

Embodiment 1

[0035] Take 100ml of sludge from the secondary settling tank of urban sewage plant, the concentration of which is MLSS (mixed solid suspended solids) is 16.52g / L. Microwave pretreatment was performed for 2 minutes, and the power of the microwave reactor was 560W. To release the organic nutrients in the sludge, kill the methanogens and pathogenic bacteria at the same time, and release some heavy metals adsorbed in the sludge. After pretreatment, the nutrients in the sludge were released, and the protein content of the original sludge increased from 25.40mg / L to 410.52mg / L; the carbohydrate content increased from 18.72mg / L to 202.65mg / L; SCOD (Soluble COD) increased from 1520mg / L of the original sludge to 2840mg / L.

[0036]Then put the pretreated sludge in a serum bottle, add 5ml of hydrogen production seed sludge, control the temperature at 35°C, and blow nitrogen for 5 minutes to remove the oxygen in the air above the remaining sludge and maintain the anaerobic state of the f...

Embodiment 2

[0038] Take 1 liter of anaerobic granular sludge and heat it in a water bath at 80°C for 2 hours as a seed sludge for hydrogen production.

[0039] 10 liters of residual sludge from a sewage plant with an MLSS of 15.21g / L is pumped into the microwave reactor 2 through the raw sludge inlet 1 by the transfer pump 12, and the pretreatment is 10 minutes with a power of 800W. Then another delivery pump 12 continuously pumps the pretreated sludge into the fermentation hydrogen production reactor 5 through the sludge inlet 3 through the pipeline, adds 1 liter of hydrogen production seed sludge, and controls the temperature to 35°C through the heater. Turn on the agitator 6 to mix the hydrogen-producing seed mud and the sludge evenly. Hydrogen is produced after 12 hours, and the hydrogen is collected by the hydrogen collection device 7 through the hydrogen outlet 11. On average, every 10 liters of sludge can produce 1000-3000ml of hydrogen, the maximum hydrogen production rate is 10....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com