Coextrusion waterproof moisture permeable thin-film structure and textile

A waterproof and moisture-permeable, film-structured technology, applied in protective clothing, layered products, synthetic resin layered products, etc., can solve the problems of film clumping and mold blockage, and achieve the effect of overcoming mold blockage and good moisture permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

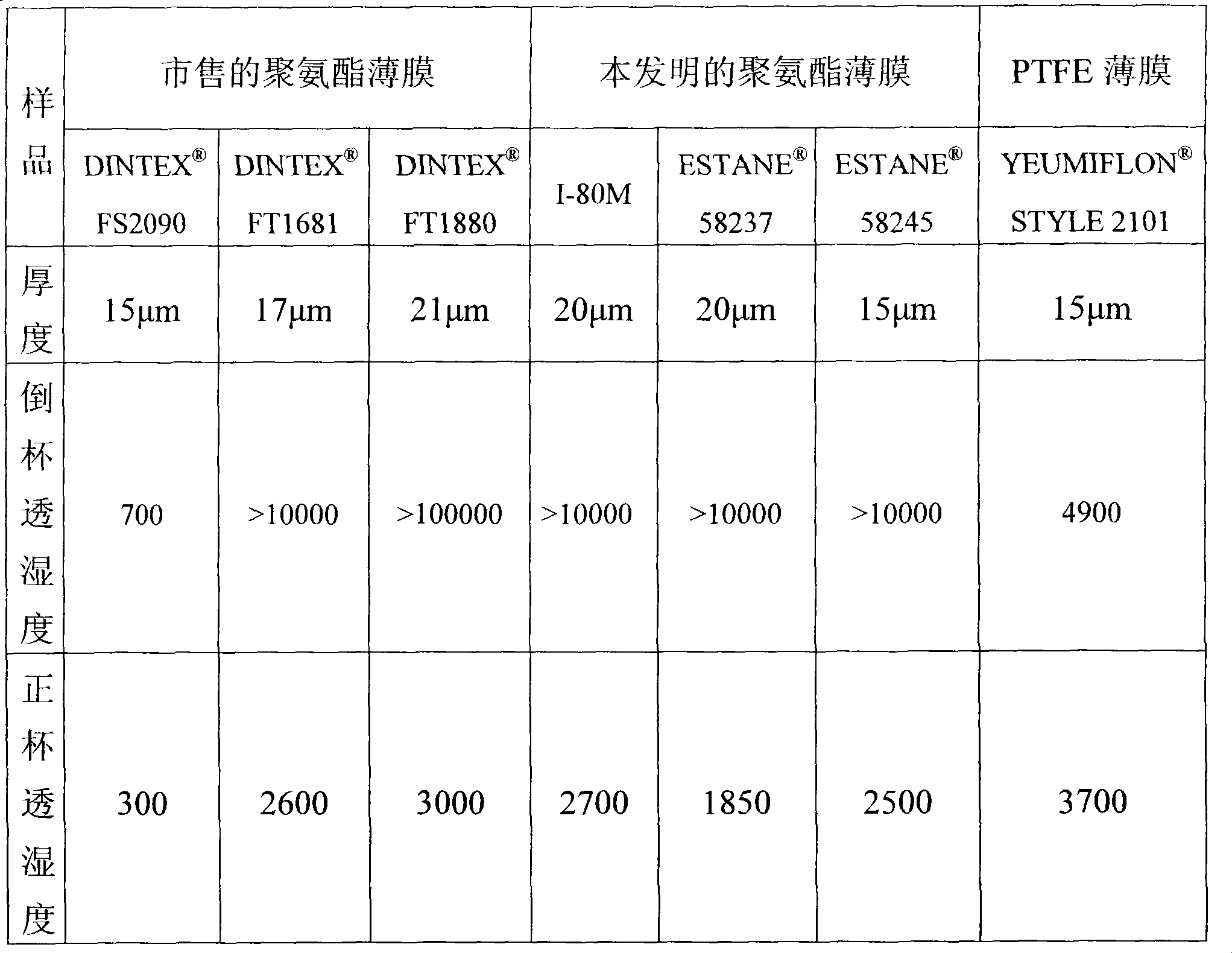

[0035] In this example, a three-layer co-extruded waterproof and moisture-permeable film structure is obtained by blown film processing, the top surface layer is 20 μm thick LDPE (Taiwan Polymer Chemicals Co., Ltd., 100 plastic NA112-27); the middle layer is 20 μm thick Polyurethane I-80M (Institute of Industrial Technology), which has a hard segment structure TDI and a soft segment structure PEG, the ratio of the two is 0.83:0.17; and LDPE with a thickness of 20 μm on the bottom surface (Taiwan Polymer Chemicals Co., Ltd. -27). The inflation ratio set by the blown film processing method is 2.0. The LDPE of the top surface layer and the bottom surface layer of the film was peeled off, and only the I-80M layer was used for the moisture permeability test such as ASTM E96 BW and JIS 1099 A-2. The obtained data are shown in Table 1. ASTM E96 BW is a method for measuring the moisture permeability of an inverted cup, which is to cover the water cup on the film at 25°C with an exter...

Embodiment 2

[0037] In this embodiment, a three-layer co-extruded waterproof and moisture-permeable film structure is obtained by blown film processing. The top surface layer is 20 μm thick LLDPE 118W (Saudi Basic Industries Corporation); the middle layer is 20 μm thick polyurethane (available from Noveon) 58245); and a bottom surface layer of LLDPE118W (Saudi Basic Industries Corporation) 20 μm thick. The inflation ratio set by the blown film processing method is 2.0. Peel off the top surface layer and bottom surface layer LLDPE 118W of the film, only use The 58245 layer was tested for moisture permeability according to ASTM E96 BW and JIS 1099 A-2, and the obtained data are shown in Table 1.

Embodiment 3

[0039] In this example, a three-layer co-extruded waterproof and moisture-permeable film structure is obtained by blown film processing, the top surface layer is 20 μm thick LDPE (Taiwan Polymer Chemicals Co., Ltd., 100 plastic NA112-27); the middle layer is 20 μm thick Polyurethane (purchased from Noveon's 58237); and LDPE with a thickness of 20 μm on the bottom surface (Taiwan Polymer Chemicals Co., Ltd., 100 plastic NA112-27). The inflation ratio set by the blown film processing method is 2.0. Peel off the LDPE of the top surface layer and the bottom surface layer of the film, only use The 58237 layer was tested for moisture permeability according to ASTM E96 BW and JIS 1099 A-2, and the obtained data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com