Multicomponent flux composition method capable of lowering metal-matrix composite synthesis temperature

A technology of composite materials and combination method, which is applied in the field of preparation of metal matrix composite materials by reaction synthesis, can solve the problems of unstable performance of metal matrix composite materials, difficulty in controlling the shape and size of the reinforcing phase, and increasing the gas absorption capacity of molten aluminum, etc., to achieve Effects of inhibiting the growth of generated particles, improving reaction kinetic conditions, and increasing synthesis reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: adopt pure Al as substrate, Zr(CO 3 ) 2 In situ synthesis of Al as a reactive salt 2 o 3 、Al 3 Zr particles reinforced aluminum matrix in situ composites.

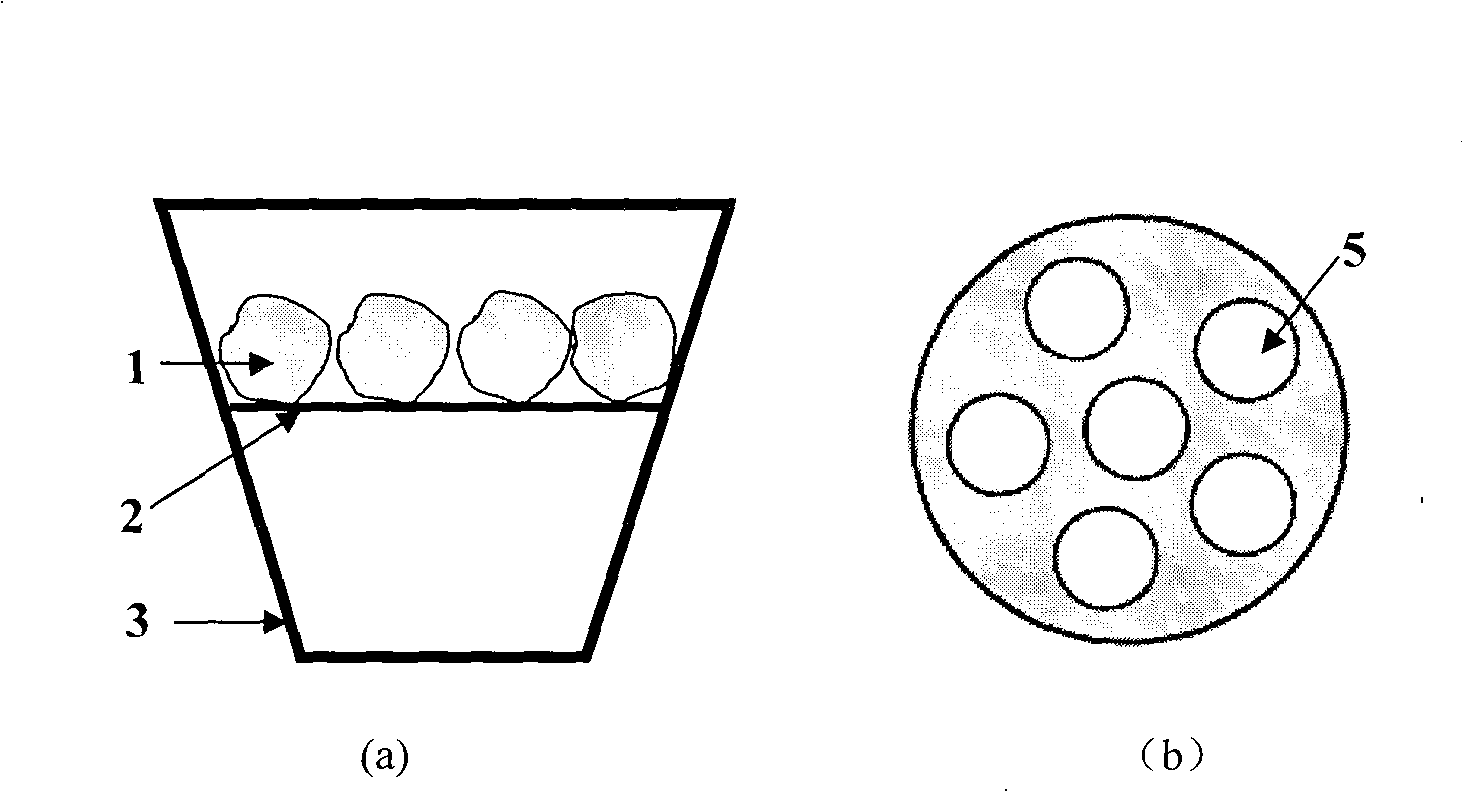

[0033] Furnace support such as figure 1 , Add No. 1 flux LiCl to the reaction salt, the amount added accounts for 1% of the total amount of the mixed salt. First, the mixed salt is baked at a low temperature of 250° C. for 3 hours. When preparing to participate in the in-situ reaction, the empty graphite crucible 3 is placed in a high-temperature furnace for heating. When the melt temperature is close to the design temperature, place the mixed salt powder bag 1 on the bracket 2, and place the mixed salt powder bag 1 in the hollow 5 as much as possible in order to prevent a large temperature gradient in the powder bag caused by conduction heat. Observe the state change of the aluminum foil after being heated for about 1 to 2 minutes. It is added into molten aluminum before it softens, and synthe...

Embodiment 2

[0034] Embodiment 2: adopt pure Al as matrix, K 2 ZrF 6 In situ synthesis of Al as a reactive salt 3Zr particles reinforced aluminum matrix in situ composites. Add No. 1 flux LiCl to the reaction salt, and the addition amount is 8% of the total weight of the mixed salt. First, bake the mixed salt at 300°C for 3 hours at a low temperature. When preparing to participate in the in-situ reaction, preheat at a high temperature according to the method in Example 1, and preheat the mixed salt package with the furnace for about 1.5 minutes. It is added into molten aluminum before softening, and then synthesized under 10Hz low-frequency electromagnetic field stirring. When the present invention is not used, the required synthesis temperature is in the range of 800-820°C. After adopting the invention, the reaction synthesis temperature can be reduced to 750-760°C, and the temperature reduction range is 40-70°C.

Embodiment 3

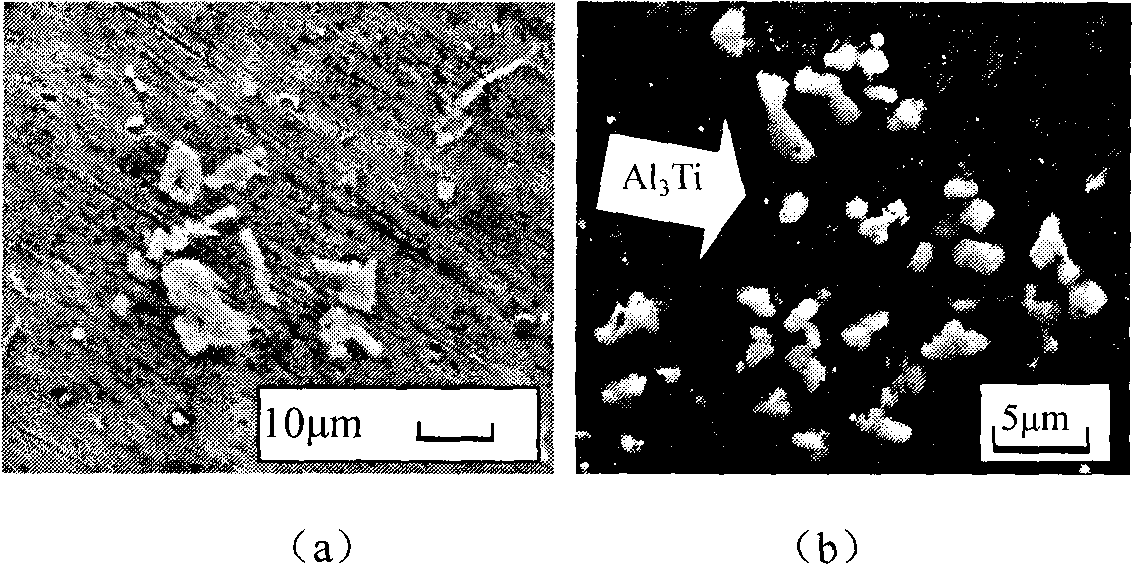

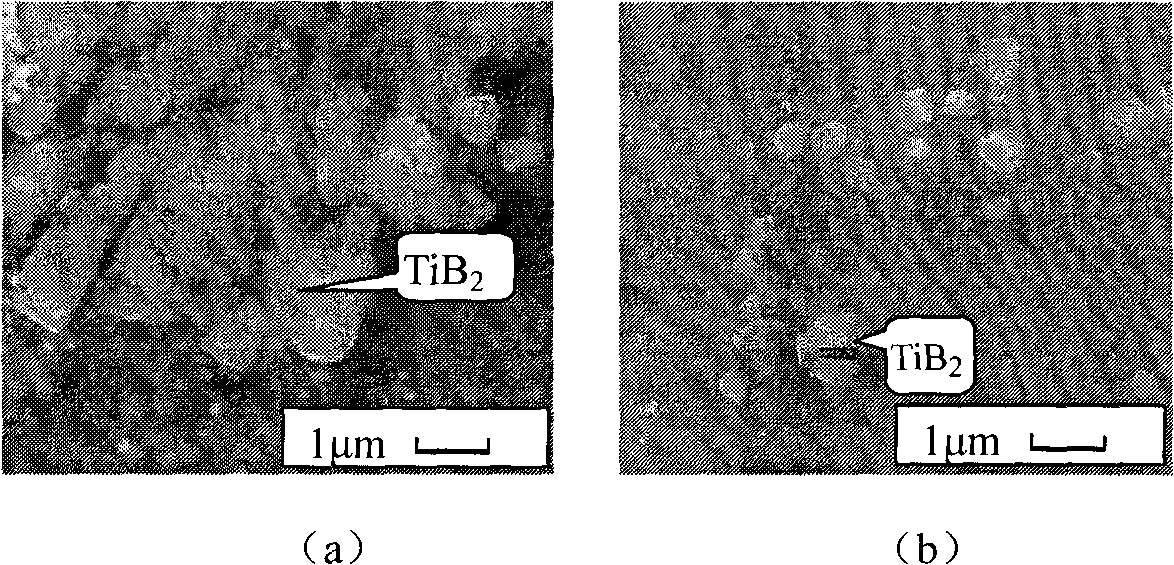

[0035] Embodiment 3: adopt pure aluminum as matrix, with K 2 TiF 6 -KBF 4 The mixture is used as a reaction salt to synthesize TiB 2 Reinforced aluminum matrix composites. The No. 1 flux LiCl is selected, and the addition amount is 3% of the total weight of the mixed salt. Firstly, the mixed salt was baked at 250°C for 3.5 hours at a low temperature. When preparing to participate in the in-situ reaction, preheat at high temperature according to the method in Example 1, preheat the mixed salt package with the furnace for 1 minute, and synthesize under 20Hz low-frequency electromagnetic field stirring. When the present invention is not used, the required synthesis temperature is in the range of 890-910°C. After the invention is adopted, the reaction synthesis temperature can be reduced to 840-850°C, and the temperature reduction range is 40-70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com