Oxidization fine purification albefaction method for montan wax

A technology for oxidative refining and montan wax, which is applied in the direction of oil/fat refining, fat production, etc., can solve the problems of food waste, glucose consumption, etc., and achieve the effects of low cost, simple operation and feasible technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

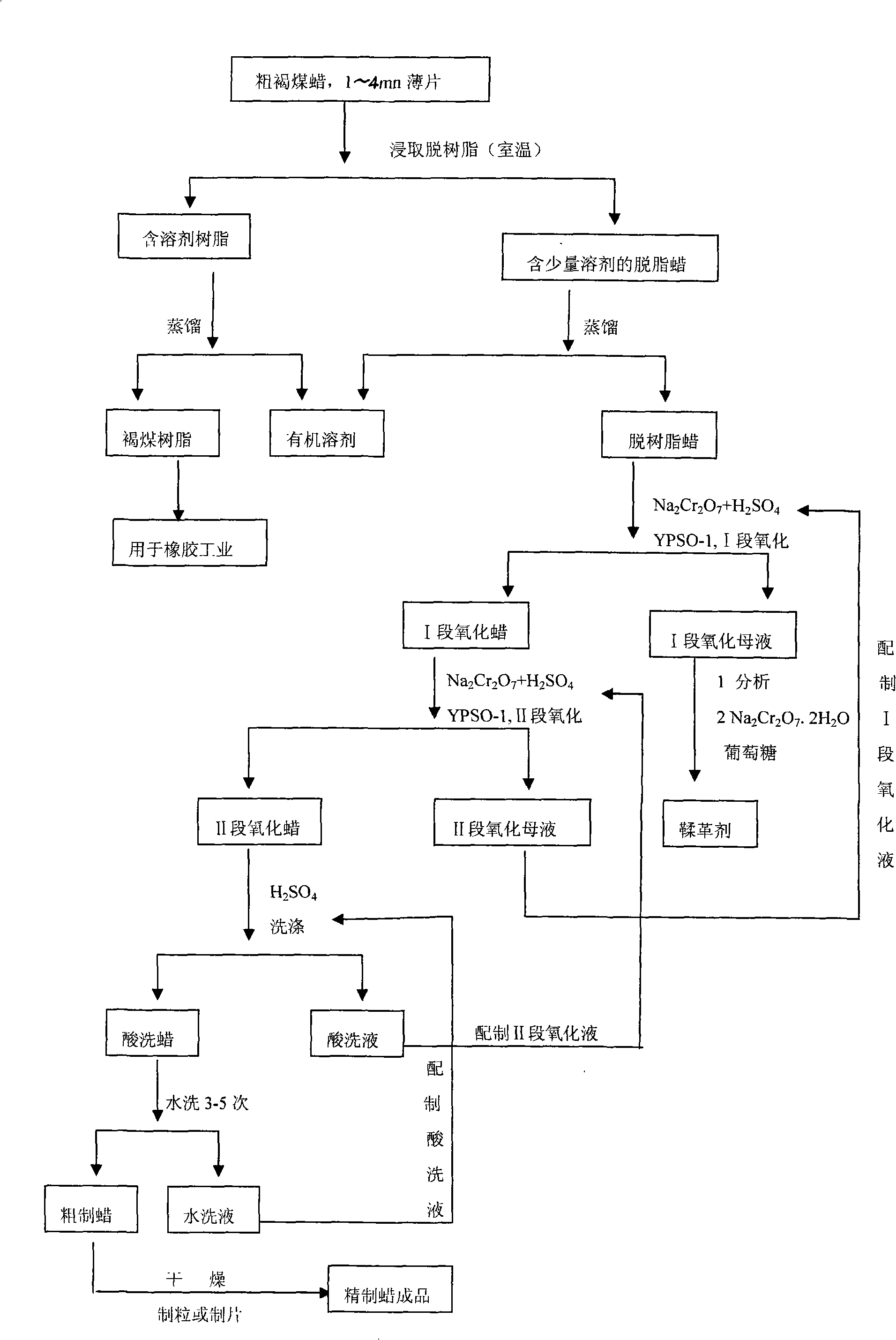

Method used

Image

Examples

Embodiment 1

[0023] A, 100 kilograms of thick montan wax flakes with a thickness of 1 to 4mm were placed in 400 liters of industrial grade ethyl acetate solvent and soaked for 24 hours, extracted 5 times at room temperature, and each extraction time was 24 hours, after which the liquid and solid were separated. phase, after reclaiming the residual ethyl acetate solvent in the solid phase, degreasing montan wax is obtained; after the extract solution dissolved with montan wax resin is evaporated and recovered ethyl acetate solvent for recycling, the residual solid is montan wax resin;

[0024] B. Put 50 kilograms of degreased montan wax in the above step A in a container with an agitator with an acid-resistant lining, add 200 kilograms of sulfuric acid solution with a concentration of 50%, heat it to 110°C under stirring, and add 10ml of YPSO dropwise -1, to prevent splashing, add 100 kilograms of concentration afterwards and be 50% sodium dichromate aqueous solution, control the reaction te...

Embodiment 2

[0030] A, 100 kilograms of thick montan wax flakes with a thickness of 1 to 3 mm were placed in 500 liters of industrial-grade ethyl acetate solvent and soaked for 15 hours, extracted 3 times at room temperature, and each extraction time was 15 hours, after which the liquid and solid were separated. phase, after reclaiming the residual ethyl acetate solvent in the solid phase, degreasing montan wax is obtained; after the extract solution dissolved with montan wax resin is evaporated and recovered ethyl acetate solvent for recycling, the residual solid is montan wax resin;

[0031] B. Put 50 kg of degreased montan wax in the above step A in a container with an agitator with an acid-resistant lining, add 300 kg of sulfuric acid solution with a concentration of 30%, heat up to 90°C under stirring, and add 10ml of YPSO dropwise -1, to prevent splashing, add 150 kilograms of concentration afterwards and be 40% potassium dichromate aqueous solution, control the reaction temperature t...

Embodiment 3

[0037] A, 100 kilograms of thick montan wax flakes with a thickness of 1 to 2 mm were placed in 600 liters of industrial grade ethyl acetate solvent and soaked for 5 hours, extracted 2 times at room temperature, and each extraction time was 5 hours, and then the liquid was separated from the solid phase, after reclaiming the residual ethyl acetate solvent in the solid phase, degreasing montan wax is obtained; after the extract solution dissolved with montan wax resin is evaporated and recovered ethyl acetate solvent for recycling, the residual solid is montan wax resin;

[0038] B. Put 50 kg of degreased montan wax in the above step A in a container with an agitator with an acid-resistant lining, add 150 kg of sulfuric acid solution with a concentration of 70%, heat up to 100°C under stirring, and add 10ml of YPSO dropwise -1, to prevent splashing, then add 125 kg of chromium dry aqueous solution with a concentration of 70%, control the reaction temperature at 120°C, stir and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com