Multifunctional crude oil demulsifying agent and method of producing the same

A crude oil demulsifier, multi-functional technology, applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of unsatisfactory, non-corrosion inhibition performance, etc., to achieve convenient source, good demulsification performance, and excellent corrosion inhibition function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

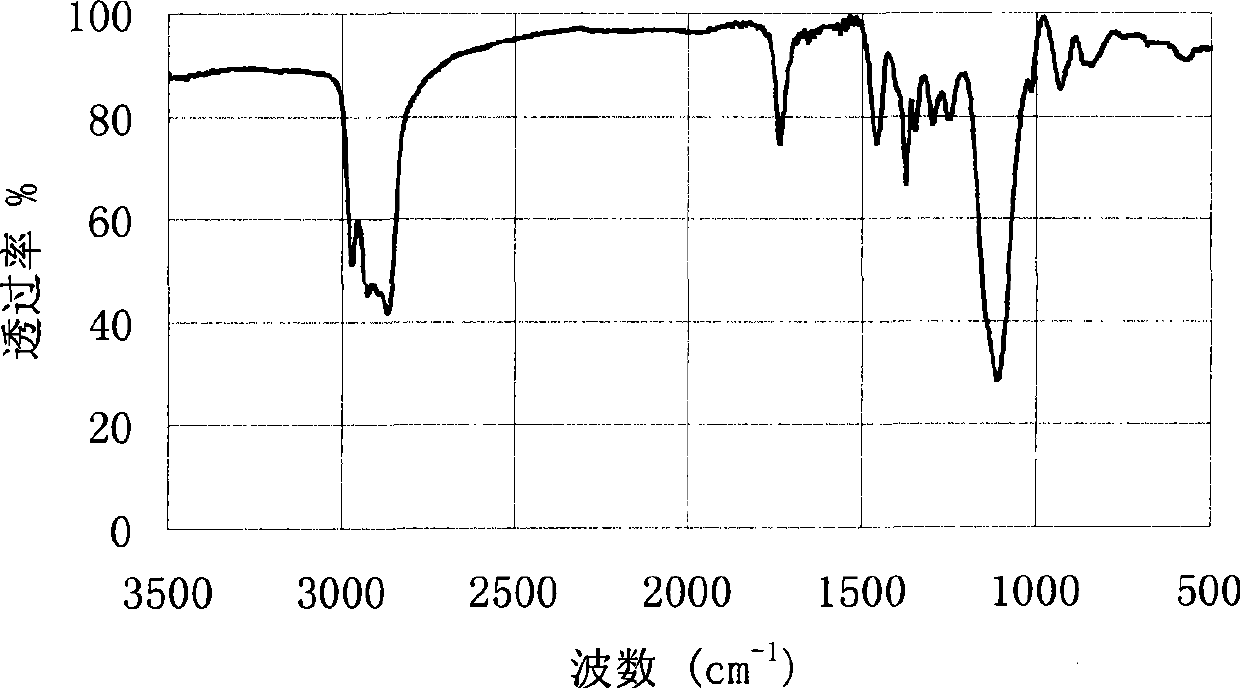

Image

Examples

Embodiment 1

[0044] (1) React a mixture of 125.5g (1.24mol) of diisopropylamine and 100g of water with 68.3g (1.37mol) of propylene oxide to obtain diisopropylisopropanolamine. The reaction temperature is 80°C and the reaction time is 2.5 Hour;

[0045] (2) Phenylamine polyoxyethylene polyoxypropylene ether, adipic acid, diisopropylisopropanolamine of step (1), catalyst p-toluenesulfonic acid and water entrained agent toluene, in an inert atmosphere, 110 ℃ React for 3h, then distill out toluene to obtain linear polyester;

[0046] The weight consumption of phenolamine polyoxyethylene polyoxypropylene ether is 500% of diisopropylisopropanolamine;

[0047] The weight consumption of adipic acid is 160% of diisopropylisopropanolamine;

[0048] The weight consumption of p-toluenesulfonic acid is 25% of diisopropylisopropanolamine;

[0049] The weight consumption of toluene is 650% of diisopropylisopropanolamine;

[0050] (3) 20 g of the product obtained in step (2) was reacted with 1 g of b...

Embodiment 2

[0061] (1) React a mixture of 125.5g (1.24mol) of diisopropylamine and 100g of water with 68.3g (1.37mol) of propylene oxide to obtain diisopropylisopropanolamine. The reaction temperature is 80°C and the reaction time is 2.5 Hour;

[0062] (2) with octylphenol polyoxyethylene polyoxypropylene ether, adipic acid, the diisopropyl isopropanolamine of step (1), catalyzer p-toluenesulfonic acid and water entrained agent toluene, in inert atmosphere, 110 ℃ for 3 hours, then distill off the toluene to obtain linear polyester;

[0063] The weight consumption of octylphenol polyoxyethylene polyoxypropylene ether is 550% of diisopropylisopropanolamine;

[0064] The weight consumption of adipic acid is 160% of diisopropylisopropanolamine;

[0065] The weight consumption of p-toluenesulfonic acid is 25% of diisopropylisopropanolamine;

[0066] The weight consumption of toluene is 850% of diisopropylisopropanolamine;

[0067] (3) 18 g of the product obtained in step (2) was reacted wi...

Embodiment 3

[0078] (1) react a mixture of 157.0 g (1.0 mol) of decylamine and 150 g of water with 128 g (2.2 mol) of propylene oxide to obtain decyl isopropanolamine, the reaction temperature is 80° C., and the reaction time is 2 hours;

[0079] (2) Propylene glycol polyoxyethylene polyoxypropylene ether, adipic acid, decanyl isopropanolamine in step (1), catalyst p-toluenesulfonic acid, and water-entraining agent toluene are reacted at 110° C. for 3 h in an inert atmosphere, Then distill out toluene to obtain linear polyester;

[0080] The weight consumption of propylene glycol polyoxyethylene polyoxypropylene ether is 600% of decanyl isopropanolamine;

[0081] The weight consumption of adipic acid is 180% of decyl isopropanolamine;

[0082] The weight consumption of p-toluenesulfonic acid is 28% of decyl isopropanolamine;

[0083] The weight consumption of toluene is 750% of decyl isopropanolamine;

[0084] (3) 20 g of the product obtained in step (2) was reacted with 1 g of benzyl c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com