Uses of allyloxy hydroxide sodium dimercaptosulphanate in PVC processing aid

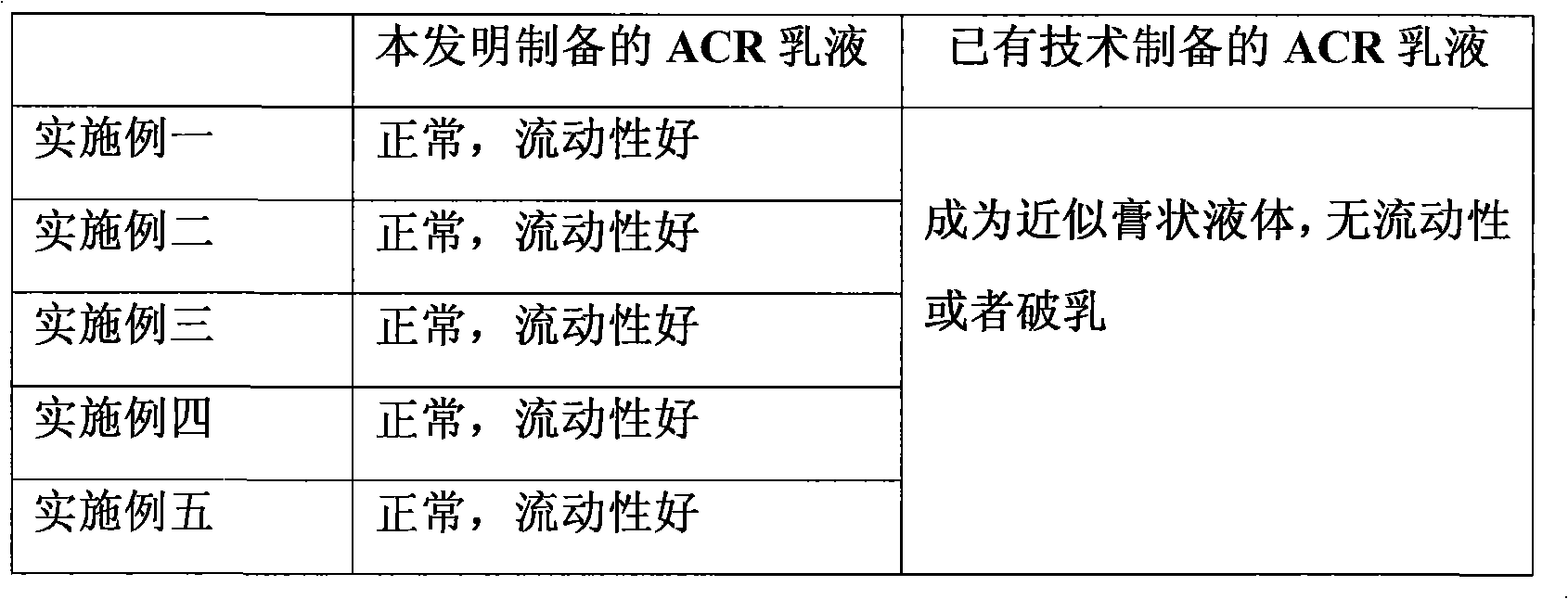

The technology of sodium allyloxy hydroxypropanesulfonate and processing aid is applied in the application field of reactive emulsifier in PVC processing aid, which can solve the problem of affecting the wall-sticking performance of PVC and aggravating the processing aid ACR in spray tower. Severity of sticking towers, reduced spray drying rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Add 800kg of soft water, 1.1kg of one-stage emulsifier sodium allyloxy hydroxypropyl sulfonate, one-stage monomer (220kg of ethyl acrylate, 220kg of methyl methacrylate and 660kg of butyl acrylate) in the reactor, close the reactor, and heat up , nitrogen protection, when the temperature rises to 75°C, add an initiator (potassium persulfate or ammonium persulfate 8.8kg) to initiate the reaction. After the reaction starts, the temperature rises, and the cooling water is turned on to control the reaction temperature below 88°C. After completion of the reaction, when the temperature dropped to 75° C., 1.1 kg of the second-stage emulsifier allyloxy hydroxypropyl sulfonate, two-stage monomers (220 kg of ethyl acrylate, 220 kg of methyl methacrylate and 660 kg of butyl acrylate) were added, Start the second stage reaction. After the reaction starts, the temperature rises, and the cooling water is turned on to control the reaction temperature not to exceed 85° C. After the rea...

Embodiment 2

[0012] Add 800kg of soft water, 3.3kg of one-stage emulsifier sodium allyloxy hydroxypropyl sulfonate, one-stage monomer (220kg of ethyl acrylate, 220kg of methyl methacrylate and 660kg of butyl acrylate) in the reactor, close the reactor, and heat up , nitrogen protection, when the temperature rises to 75°C, add an initiator (potassium persulfate or ammonium persulfate 10kg) to initiate the reaction. After the reaction starts, the temperature rises, and the cooling water is turned on to control the reaction temperature below 88°C. After completion, when the temperature drops to 75°C, add 3.3 kg of the second-stage emulsifier allyloxy hydroxypropyl sulfonate, and the second-stage monomer (220 kg of ethyl acrylate, 220 kg of methyl methacrylate and 660 kg of butyl acrylate), and start Second stage reaction. After the reaction starts, the temperature rises, and the cooling water is turned on to control the reaction temperature not to exceed 85° C. After the reaction is completed...

Embodiment 3

[0014] Add 800kg of soft water, 5.5kg of one-stage emulsifier sodium allyloxy hydroxypropyl sulfonate, one-stage monomer (220kg of ethyl acrylate, 220kg of methyl methacrylate and 660kg of butyl acrylate) in the reactor, close the reactor, and heat up , nitrogen protection, when the temperature rises to 75°C, add an initiator (potassium persulfate or ammonium persulfate 18kg) to initiate the reaction. After the reaction starts, the temperature rises, and the cooling water is turned on to control the reaction temperature below 88°C. After completion, when the temperature drops to 75°C, add 5.5 kg of the second-stage emulsifier allyloxy hydroxypropyl sulfonate, the second-stage monomer (220 kg of ethyl acrylate, 220 kg of methyl methacrylate and 660 kg of butyl acrylate), and start Second stage reaction. After the reaction starts, the temperature rises, and the cooling water is turned on to control the reaction temperature not to exceed 85° C. After the reaction is completed, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com