Carbon fiber reinforced plastic pipe and preparation process thereof

A preparation process, a technology of plastic pipes, applied in the field of plastic pipes, can solve the problems of troublesome operation and maintenance of industrial equipment, insufficient toughness and changes in toughness, and difficult processing of pipes, etc., to achieve shortened plasticization time, easy deep drawing, and remarkable durability The effect of aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

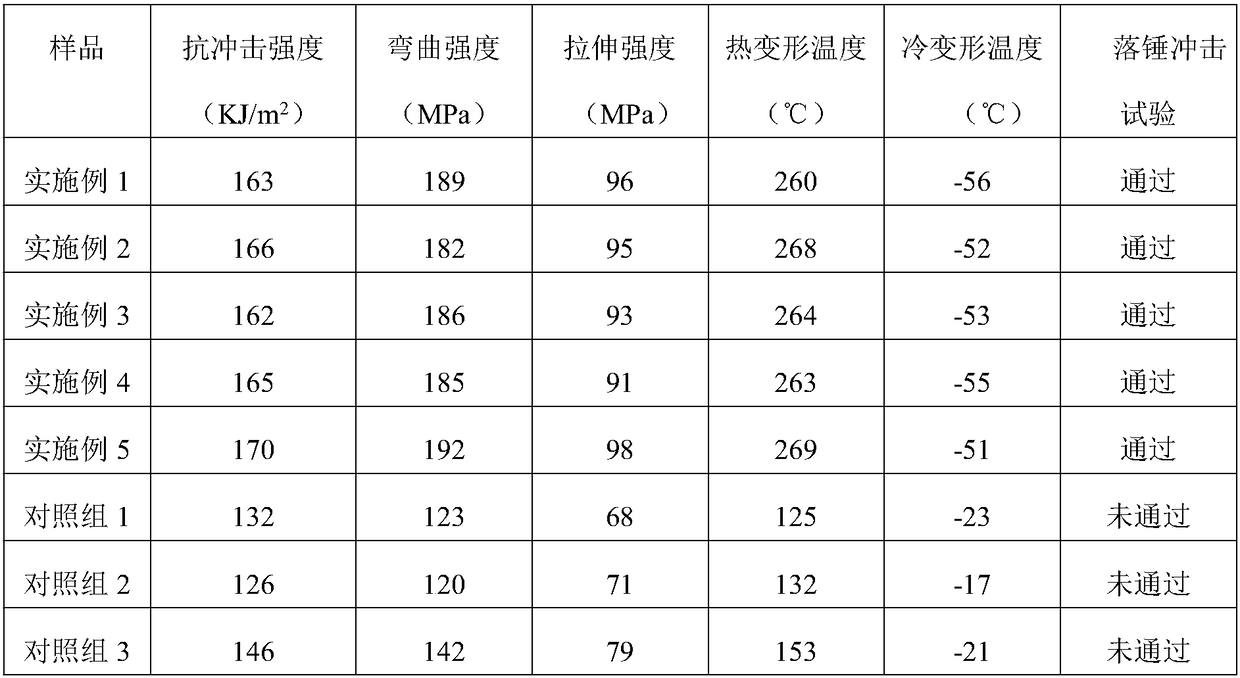

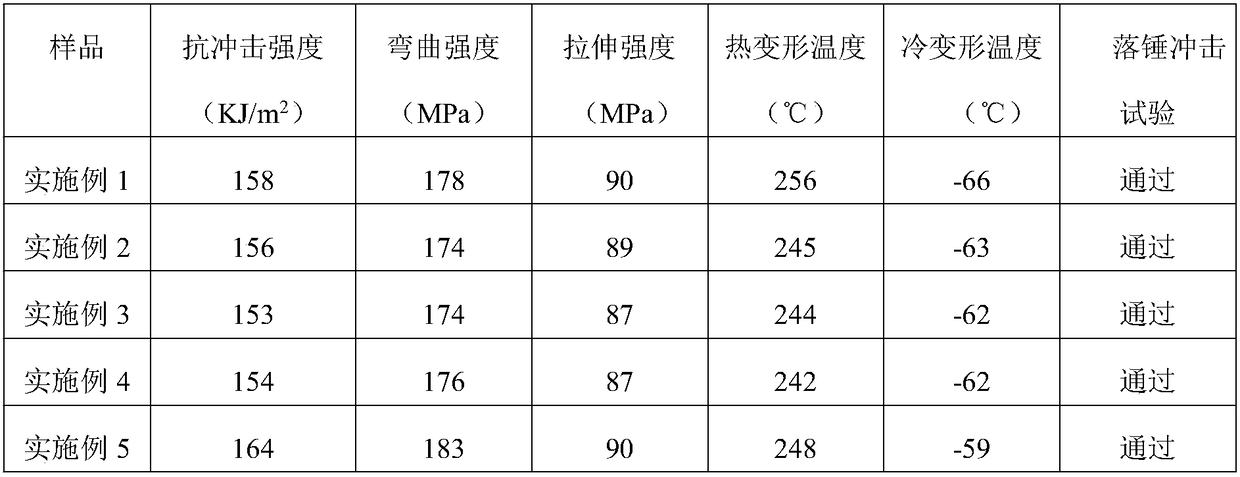

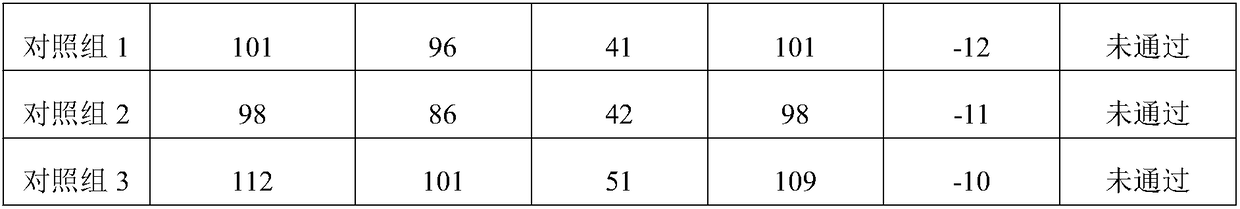

Examples

Embodiment 1

[0026] Prepare a carbon fiber reinforced plastic pipe, comprising the following steps:

[0027] 1) Weigh 100 parts of polyethylene resin according to the required parts by weight, 4 parts of chopped carbon fiber with a length of 6mm, 8 parts of impact modifier MBS auxiliary agent, 0.1 part of hyperbranched polyamide, 4 parts of graphene, zinc oxide 4 parts; the impact modifier is MBS, and the auxiliary agent is a terpolymer of methyl methacrylate (M), butadiene (B) and styrene (S).

[0028] 2) Put the graphene and hyperbranched polyamide weighed in step 1) into a mixer and mix them evenly, and control the temperature at 90±5°C with a stirring speed of 1500r / min and a stirring time of 15 minutes for stirring and mixing, Obtain mixture I;

[0029] 3) Add the mixture prepared in step 2) and the polyethylene resin, chopped carbon fiber, impact modifier and zinc oxide weighed in step 1) into a mixer and mix them, and control the temperature at 75±5°C With the stirring speed of 80...

Embodiment 2

[0034] Prepare a carbon fiber reinforced plastic pipe, comprising the following steps:

[0035] 1) Weigh 200 parts of polyethylene resin according to the required parts by weight, 12 parts of chopped carbon fiber with a length of 2mm, 50 parts of impact modifier ABS auxiliary agent, 12 parts of hyperbranched polyamide, 20 parts of graphene, zinc oxide 15 parts; ABS auxiliary agent is acrylonitrile-styrene-butadiene copolymer.

[0036] 2) Put the graphene and hyperbranched polyamide weighed in step 1) into a mixer and mix them evenly, and control the temperature to be 1800r / min at a stirring speed of 1800r / min under the condition of controlling the temperature at 90±5°C, and stir and mix them evenly for 20min, Obtain mixture I;

[0037] 3) Add the mixture prepared in step 2) and the polyethylene resin, chopped carbon fiber, impact modifier and zinc oxide weighed in step 1) into a mixer and mix them, and control the temperature at 75±5°C After the stirring speed is 1000r / min a...

Embodiment 3

[0042] Prepare a carbon fiber reinforced plastic pipe, comprising the following steps:

[0043] 1) Weigh 120 parts of polyethylene resin according to the required parts by weight, 5 parts of chopped carbon fiber with a length of 4 mm, 10 parts of impact modifier MBS auxiliary agent, 0.2 part of hyperbranched polyamide, 6 parts of graphene, zinc oxide 6 parts; MBS additive is a terpolymer of methyl methacrylate (M), butadiene (B) and styrene (S).

[0044] 2) Put the graphene and hyperbranched polyamide weighed in step 1) into a mixer and mix them evenly, and control the temperature at 90±5°C with a stirring speed of 1600r / min and a stirring time of 16min for stirring and mixing, Obtain mixture I;

[0045] 3) Add the mixture prepared in step 2) and the polyethylene resin, chopped carbon fiber, impact modifier and zinc oxide weighed in step 1) into a mixer and mix them, and control the temperature at 75±5°C After the stirring speed is 900r / min and the stirring time is 12min, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com