Apparatus for recycling the disposed slurry produced in the manufacturing process of the silicon wafer

A manufacturing process and recycling technology, applied in the direction of manufacturing tools, stone processing equipment, metal processing equipment, etc., can solve the problems of complex slurry recycling equipment, achieve excellent recycling efficiency, simple operation principle, and minimize process time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

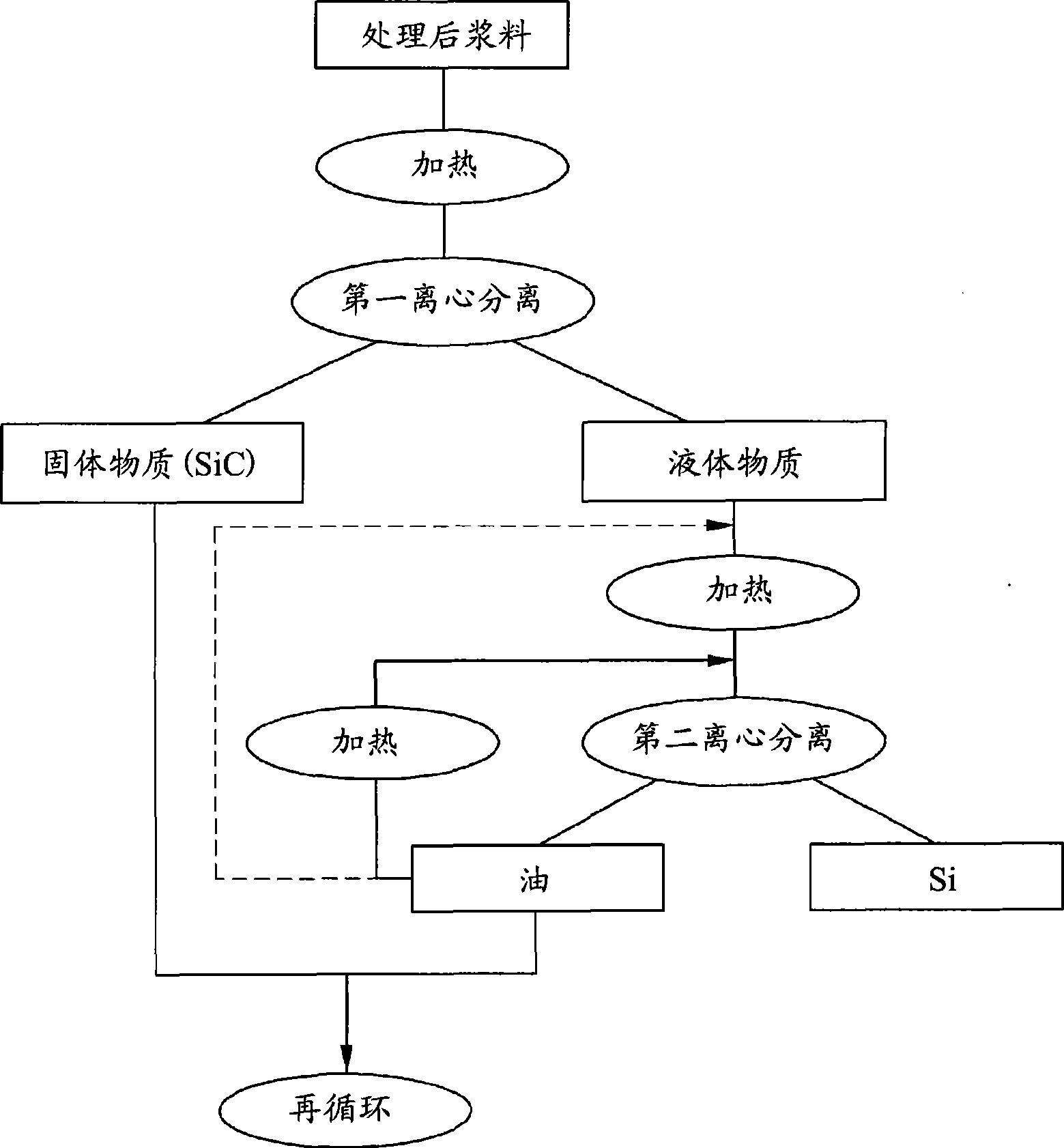

[0042] figure 1 is a schematic diagram of a process for separating and recycling abrasives, sawdust, and cutting oil from a used slurry according to an exemplary embodiment of the present invention.

[0043] In order to recycle the used slurry by separating and recovering abrasive and cutting oil from the used slurry, two centrifugation steps are performed.

[0044] A first centrifugal separation step is performed to separate the used slurry into a solid substance mainly containing an abrasive made of SiC and a first liquid substance mainly containing cutting oil. Then, a second centrifugation step is performed at high speed to remove finely divided Si sawdust from the first liquid substance, thereby recirculating the cutting oil, which has a density similar to fresh oil, eg, 0.89 g / cc.

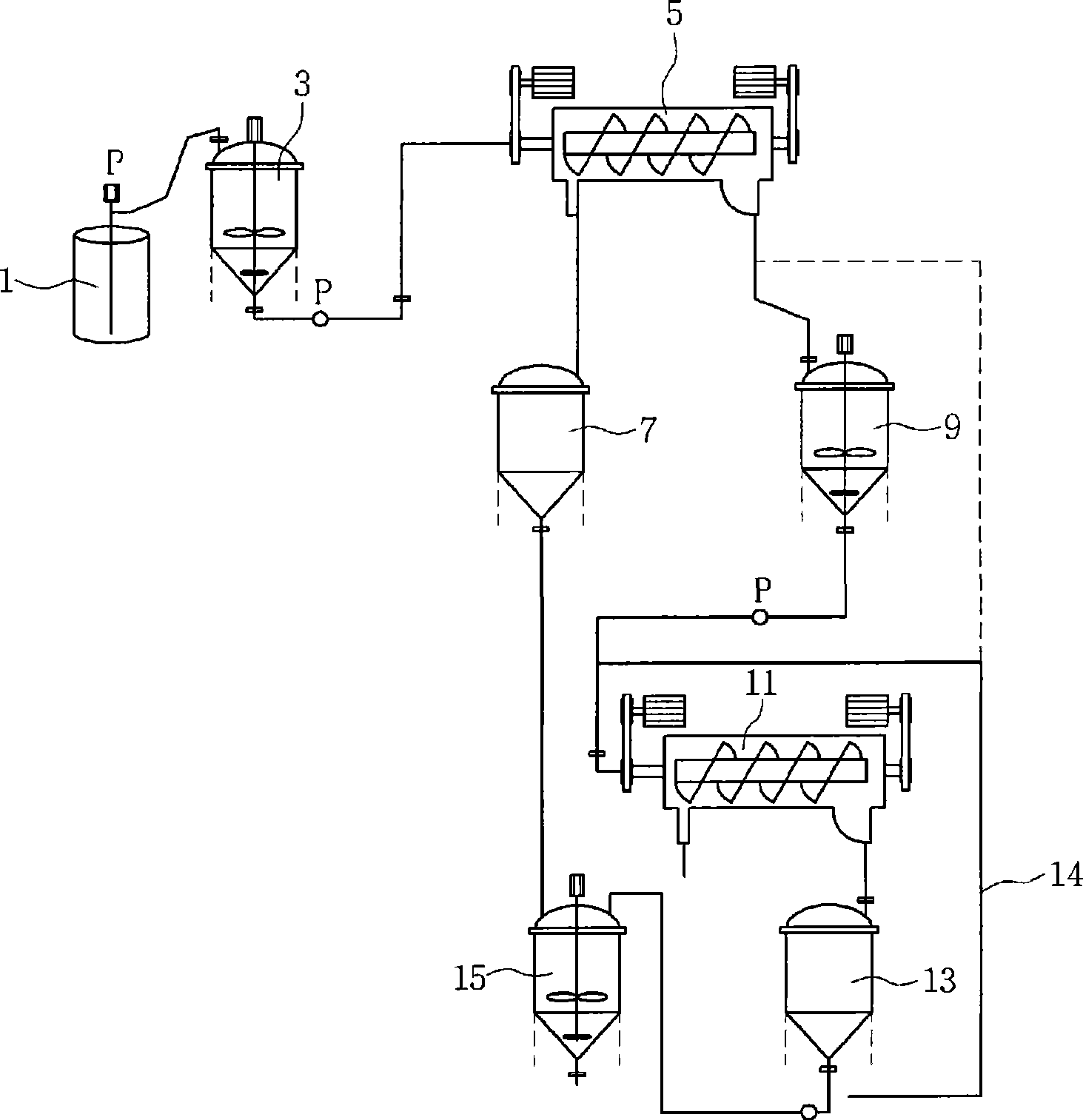

[0045] figure 2 for execution figure 1 A sketch of the equipment for recycling used slurry for the process shown.

[0046] The used slurry that has flowed into the tank car or drum 1 is fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com