High density lithium iron phosphate and method for synthesizing

A technology of lithium iron phosphate and its synthesis method, which is applied in phosphorus compounds, chemical instruments and methods, and electrode manufacturing, and can solve problems such as slow mass transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

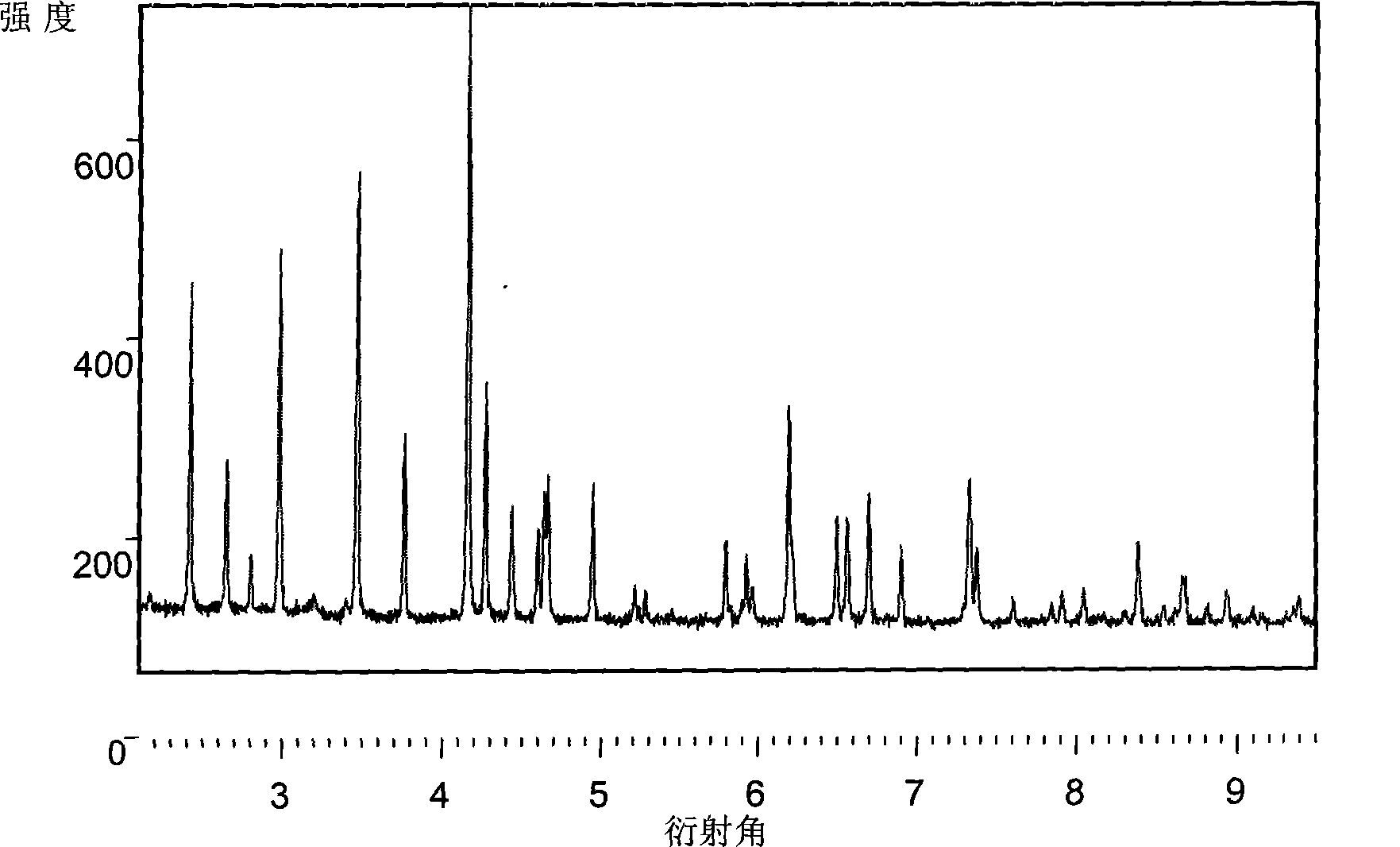

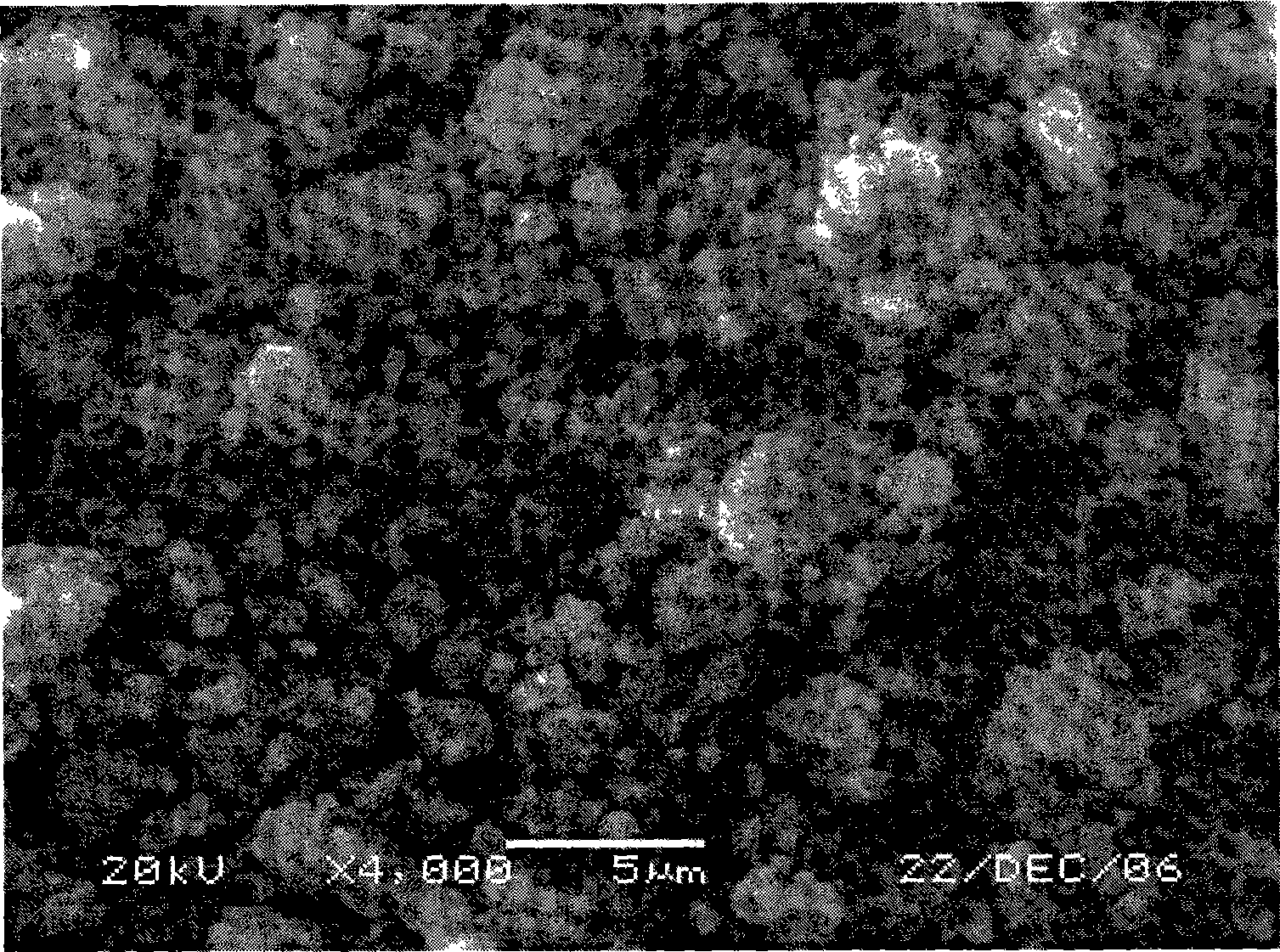

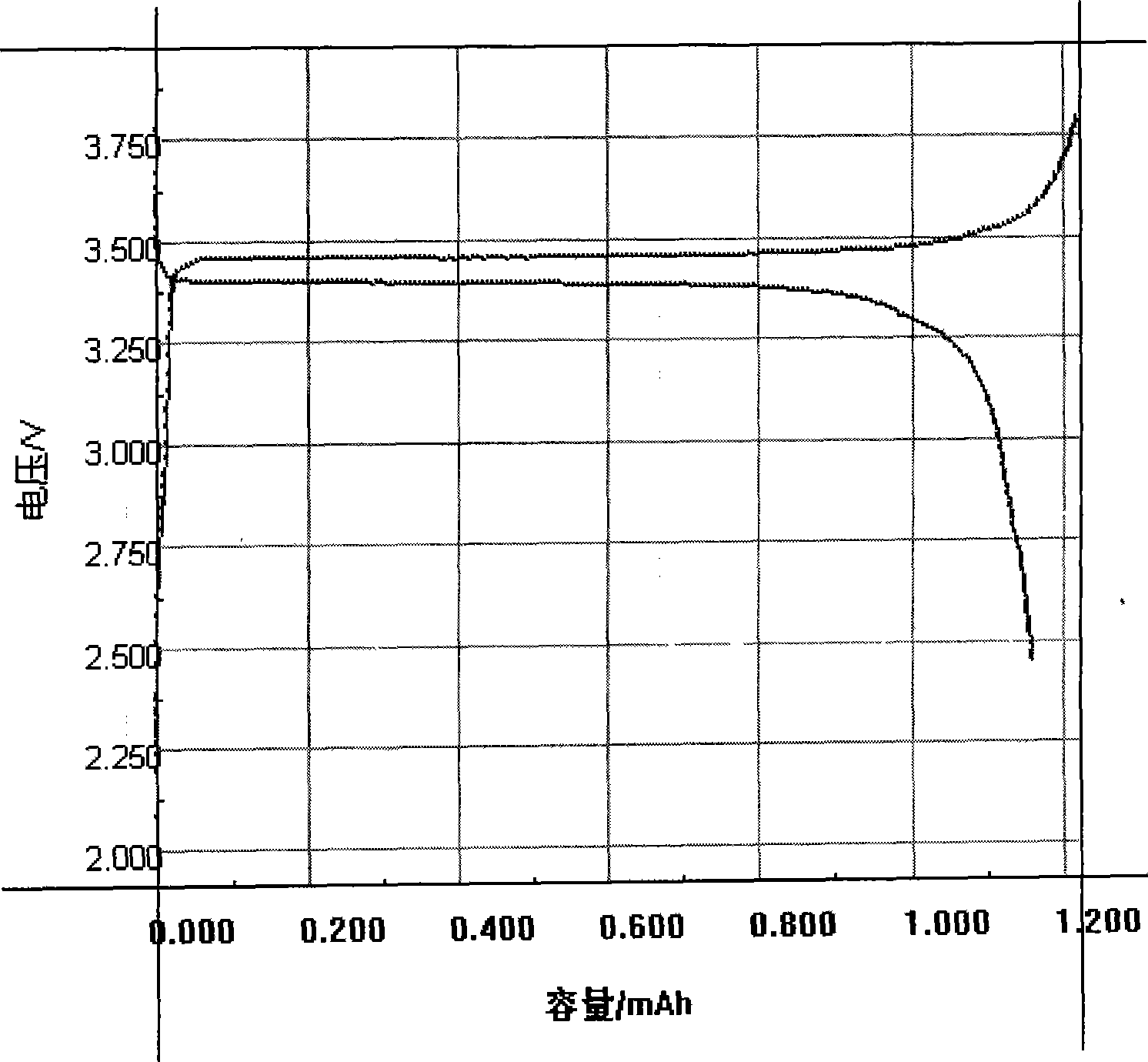

Embodiment 1

[0025] Weigh Li 2 CO 3 34.7g, NH 4 h 2 PO 4 111.6g, FeC 2 o 4 2H 2 O 180g, Li 2 PO 3 F3.3g, sucrose 19g, after these five kinds of raw materials are mixed evenly by dry method, slowly add in the beaker that 350ml water is housed under stirring state, wait for CO 2 After basically escaping, move it into a 3L ball mill jar for ball milling for 3 hours. Put the slurry mixed by ball milling into a tray, dry it in an oven at 110°C, and ball mill the dry material for 3 hours. The obtained powder is punched by a granulator into 10mm granular, put the granular material into the crucible, heat up to 750°C at 5°C / min in the atmosphere protection furnace, keep the temperature for 6h, stop heating, and naturally cool to room temperature, the protection gas used in the roasting process is N 2 , the calcined material is crushed to 150 mesh by ball milling to obtain lithium iron phosphate product, the tap density of this product is 1.45g / cm 3 . Lithium iron phosphate product, ac...

Embodiment 2

[0027] Weigh LiOH·H 2 O 41.2g, NH 4 h 2 PO 4 112.7g, FeC 2 o 4 2H 2 O 180g, Na 2 PO 3 F2.9g, glucose 16.5g, ethanol 400ml, put the above materials into a 3L ball mill jar, and ball mill and mix for 2h. Put the mixed slurry into a tray, dry it in an oven at 80°C, and then ball mill the dry material for 4 hours. The obtained powder is punched into 10mm granular, put the granular material into the crucible, under N 2 In the atmosphere protection furnace, the temperature was raised to 680°C at 5°C / min, and the temperature was kept constant for 8 hours. The heating was stopped, and it was naturally cooled to room temperature. The roasted product was ground to 150 mesh by ball milling to obtain lithium iron phosphate product. The tap density of this product was 1.38g / cm 3 . The assembly and testing method of the simulated battery is the same as in Example 1, and the measured specific capacity is 135mAh / g.

Embodiment 3

[0029] Weigh LiC 2 h 3 o 2 2H 2 O 91.8g, (NH 4 ) 2 HPO 4 125.4g, FeCO 3 116g, Na 2 PO 3 F7.1g, glucose 16.5g, ethanol 400ml, put the above materials into a 3L ball mill jar, and ball mill and mix for 2h. Put the mixed slurry into a tray, dry it in an oven at 80°C, and then ball mill the dry material for 4 hours. The obtained powder is punched into 10mm granular, put the granular material into the crucible, under N 2 In the atmosphere protection furnace, the temperature was raised to 680°C at a rate of 5°C / min, and the temperature was kept constant for 8 hours. The heating was stopped, and it was naturally cooled to room temperature. The roasted product was ground to 150 mesh by ball milling to obtain lithium iron phosphate product. The tap density of this product was 1.42g / cm 3 . The assembly and testing methods of the simulated battery are the same as in Example 1, and the measured specific capacity is 140mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com