Water ultraviolet light curing epoxy acrylic ester grafted polyurethane and preparation method thereof

An epoxy acrylate, ultraviolet light technology, applied in epoxy resin coatings, coatings and other directions, can solve the problems of slow curing speed, limited application range, low hardness of paint film, etc., achieve fast curing speed, avoid volume shrinkage, High quality coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

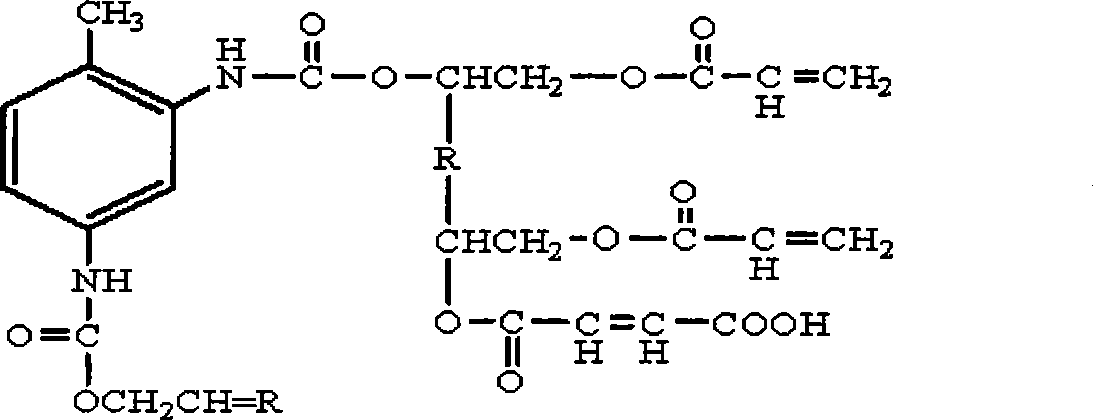

[0029] Example 1: A waterborne UV-curable epoxy acrylate grafted polyurethane prepared by the following method steps:

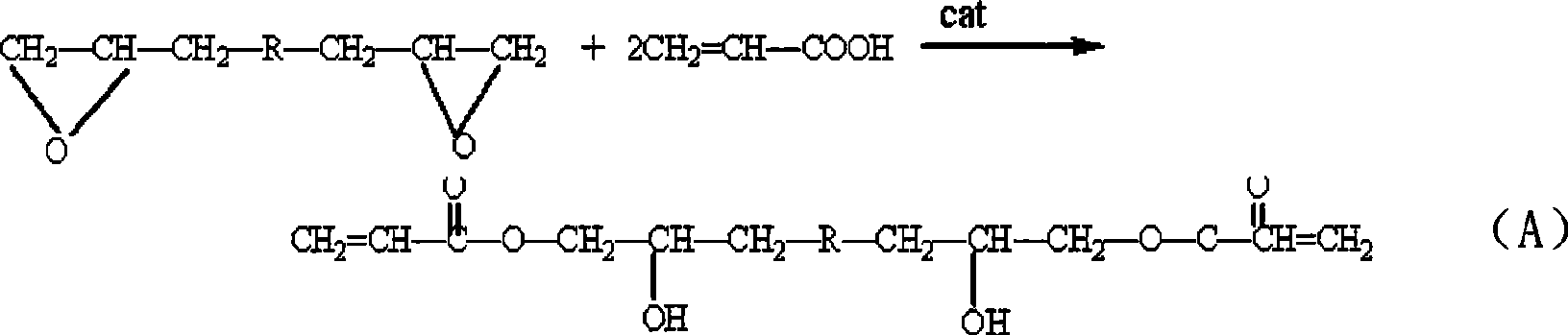

[0030] Step 1: Synthesis of epoxy acrylate resin: Add a certain amount of epoxy resin, polymerization inhibitor and catalyst into a three-necked flask equipped with a stirrer, condenser, and thermometer. The equivalent ratio of epoxy group to carboxyl group is 1:1. Add acrylic acid in the proportions, heat and stir. The temperature is raised to 90℃ within 0.5~1h, and after reaction for 2h, the temperature is rapidly raised to 110~120℃ for constant temperature reaction, and the acid value is sampled at regular intervals. When the acid value is less than or equal to 5mgKOH / g, the reaction is stopped. FT-IR (KBr) test: 913,1244 (epoxy group) disappeared; 1723 (C=O); 1611 (C=C); 3500 (OH) cm -1 ;

[0031] Step 2: Semi-addition of toluene 2, 4-diisocyanate (TDI) and unsaturated compound containing primary hydroxyl group:

[0032] Add a certain quality of toluene 2, 4-...

Embodiment 2

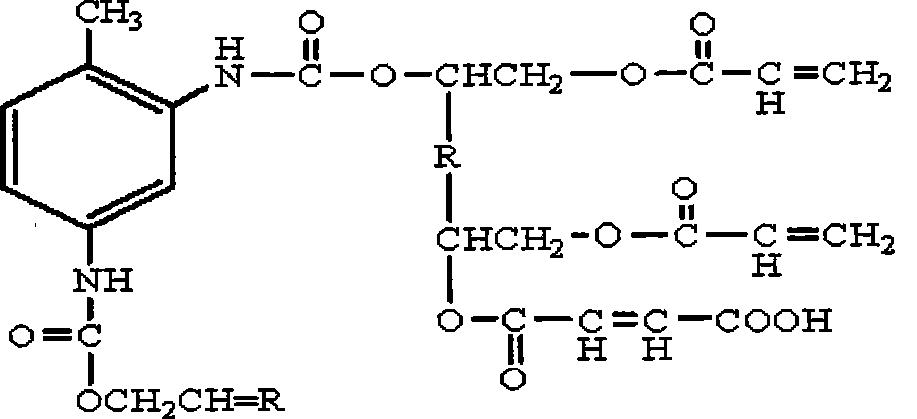

[0036] Example 2: A waterborne UV-curable epoxy acrylate grafted polyurethane is prepared by the following method steps:

[0037] Step 1: Synthesis of epoxy acrylate resin: Add a certain quality of epoxy resin, polymerization inhibitor and catalyst into a three-necked flask equipped with a stirrer, condenser, and thermometer. The equivalent ratio of epoxy group to carboxyl group is 1:1. Add acrylic acid in the proportions, heat and stir. The temperature is raised to 90℃ within 0.5~1h, and after reaction for 2h, the temperature is rapidly raised to 110~120℃ for constant temperature reaction, and the acid value is sampled at regular intervals. When the acid value is less than or equal to 5mgKOH / g, the reaction is stopped. FT-IR (KBr) test: 913,1244 (epoxy group) disappeared; 1723 (C=O); 1611 (C=C); 3500 (OH) cm -1 ;

[0038] Step 2: Semi-addition of toluene 2, 4-diisocyanate (TDI) and unsaturated compound containing primary hydroxyl group:

[0039] Add a certain quality of toluene 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com