Power supply drive device for pulse semiconductor laser test equipment

A technology of power drive and test equipment, which is applied in the direction of optical instrument test, measuring device, machine/structural component test, etc. It can solve the problems of small drive current, easily damaged lasers, damage, etc., and achieves filtering of current spikes and burrs, Easy installation and replacement, adjustable driving current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

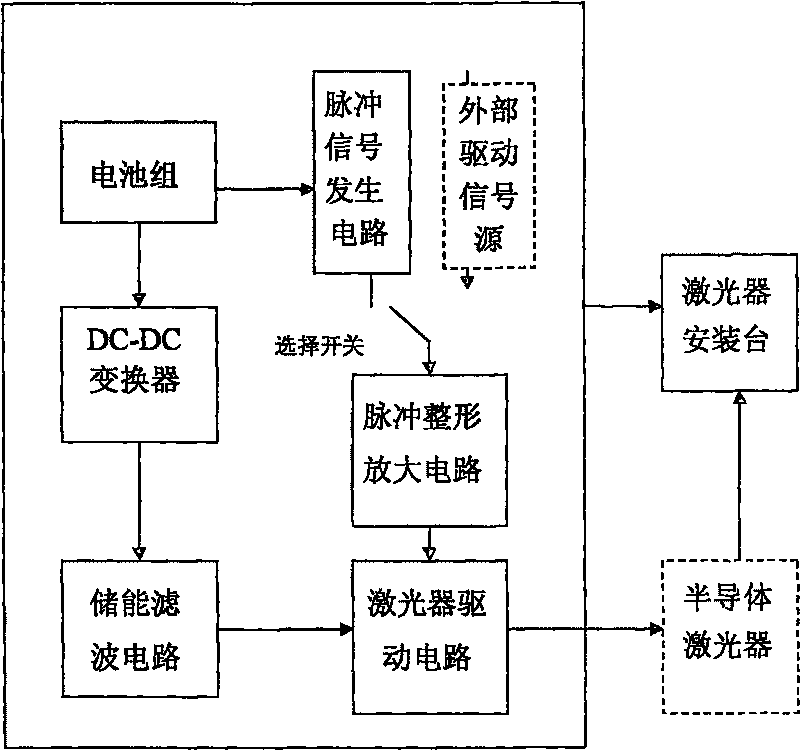

[0020] as figure 1 As shown, the preferred embodiment of the power drive device of the present invention is composed of a drive module and a laser installation assembly. The drive module is welded with a battery pack U1, an adjustable DC-DC converter U2, a pulse signal generating circuit, a signal selection switch, a pulse shaping amplifier circuit U5, a laser drive circuit U6, and an energy storage filter circuit U7.

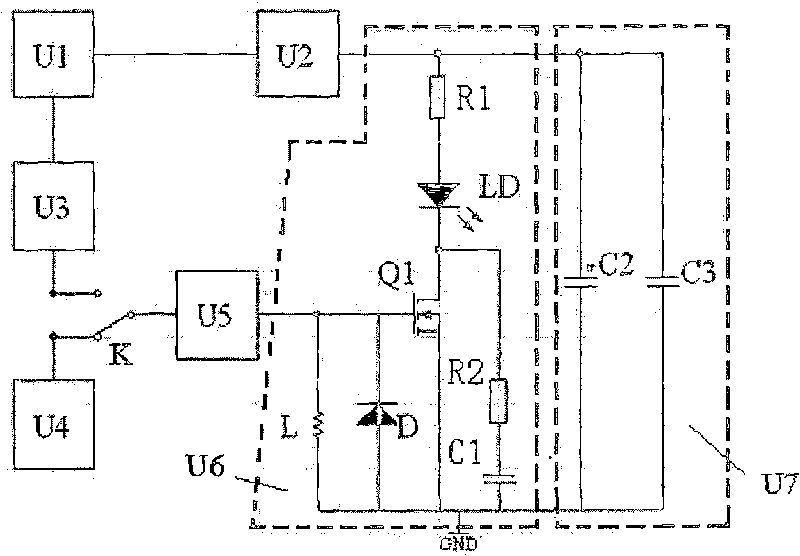

[0021] according to figure 2As shown, the battery pack U1, the adjustable DC-DC converter U2 and the energy storage filter circuit U7 constitute the power supply part of this embodiment, and its function is to provide pulse driving current for the laser LD to be tested. The battery pack U1 adopts four 12V dry batteries connected in parallel, and its function is to supply power for the adjustable DC-DC converter U2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com