Preparation for semi-conductor ferrous disilicide thin-film material

A technology of iron disilicide and thin film materials, which is applied in the field of preparation of β-FeSi2 thin films, and can solve the problems of impractical solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

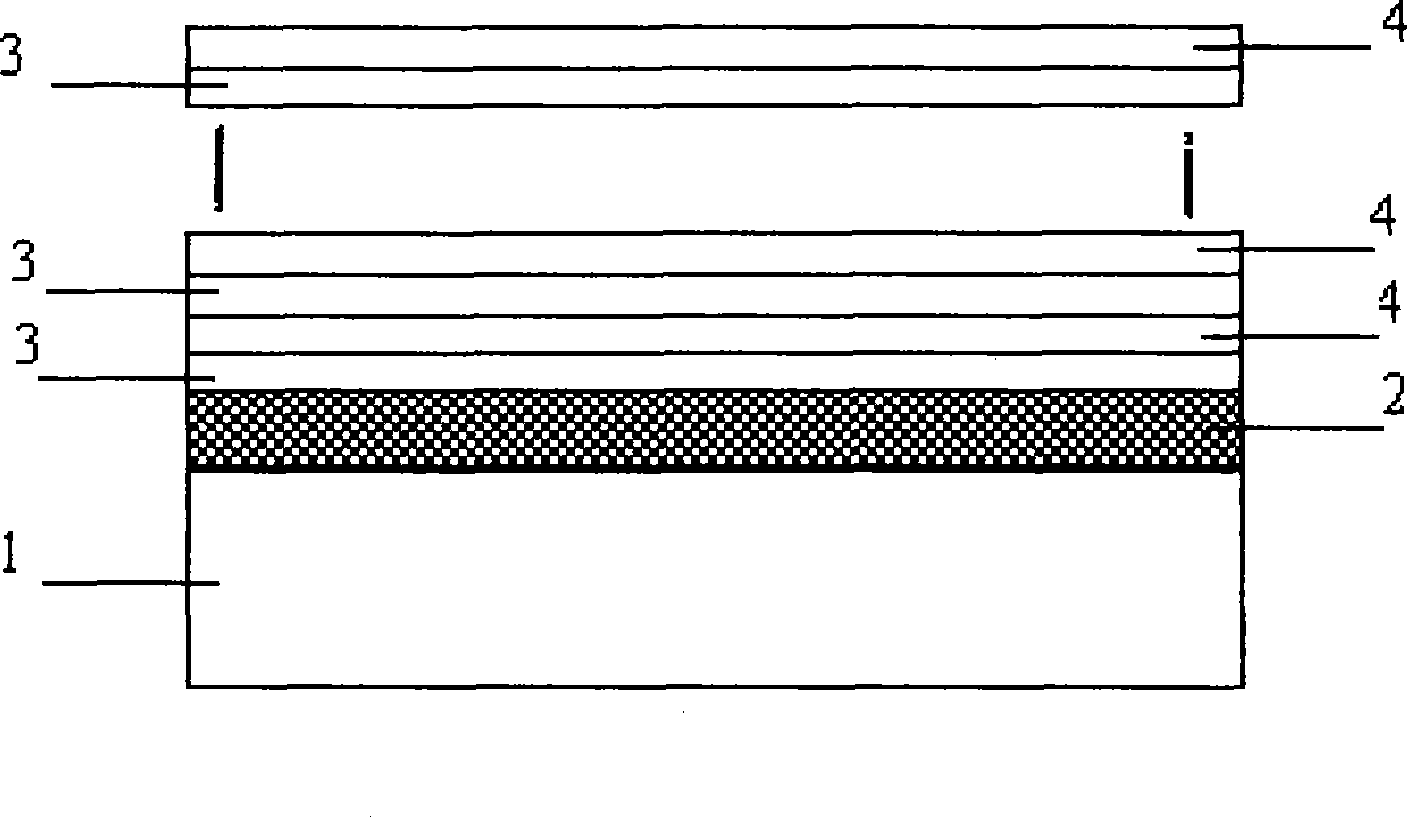

Image

Examples

no. 1 example

[0013] First Example: Using Surface Polished Al 2 o 3 The ceramic sheet is used as the substrate. After cleaning by the standard RCA process, it is placed in the magnetron sputtering chamber. The background vacuum is better than 5×10 -5 Pa, the vacuum of the deposition chamber is 0.1 Pa, and the purity of the Fe target and the Si target are 99.99% and 99.9999%, respectively. First deposit a layer of 25nm amorphous silicon film at room temperature, and then deposit 60 cycles of [Si3.3nm / Fe 1nm] multilayer film at room temperature. After annealing at 900°C for 2 hours in Ar gas atmosphere, the β-FeSi with preferred orientation of (202) was obtained 2 The thin film has a direct bandgap of 0.88eV; a resistivity of about 100Ω·cm, and weak n-type conductivity; and a photoconductive effect greater than 30% when irradiated by a 60W light source.

no. 2 example

[0014] The second embodiment: In the first embodiment, the conventional thermal annealing is changed to rapid thermal annealing, and the specific condition is to anneal at 1000°C for 15 seconds in an Ar gas atmosphere to obtain β-FeSi with a preferred orientation of (202) 2 The thin film has a direct bandgap of 0.87eV; a resistivity of about 120Ω·cm, and weak n-type conduction; when irradiated by a 60W light source, the photoconductive effect is about 35%.

no. 3 example

[0015] The third embodiment: In the first embodiment, the multilayer film structure is changed to [Si 3.3nm / Fe 1.6nm], and after annealing at 900°C for 2 hours in an Ar gas atmosphere, the β of the (202) preferred orientation is obtained. -FeSi 2 The thin film has a direct bandgap of about 0.88eV; a resistivity of about 0.3Ω·cm, and is p-type conductive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com