Gripper carriage, sheet-processing machine comprising gripper carriage and radiation dryer, and method for transporting sheets

A sheet-fed, conveying direction technology, applied in the general parts of printing machinery, printing machines, sending objects, etc., can solve the problems of variation, low resistance to rubbing and/or scratching, and achieve a good and even distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

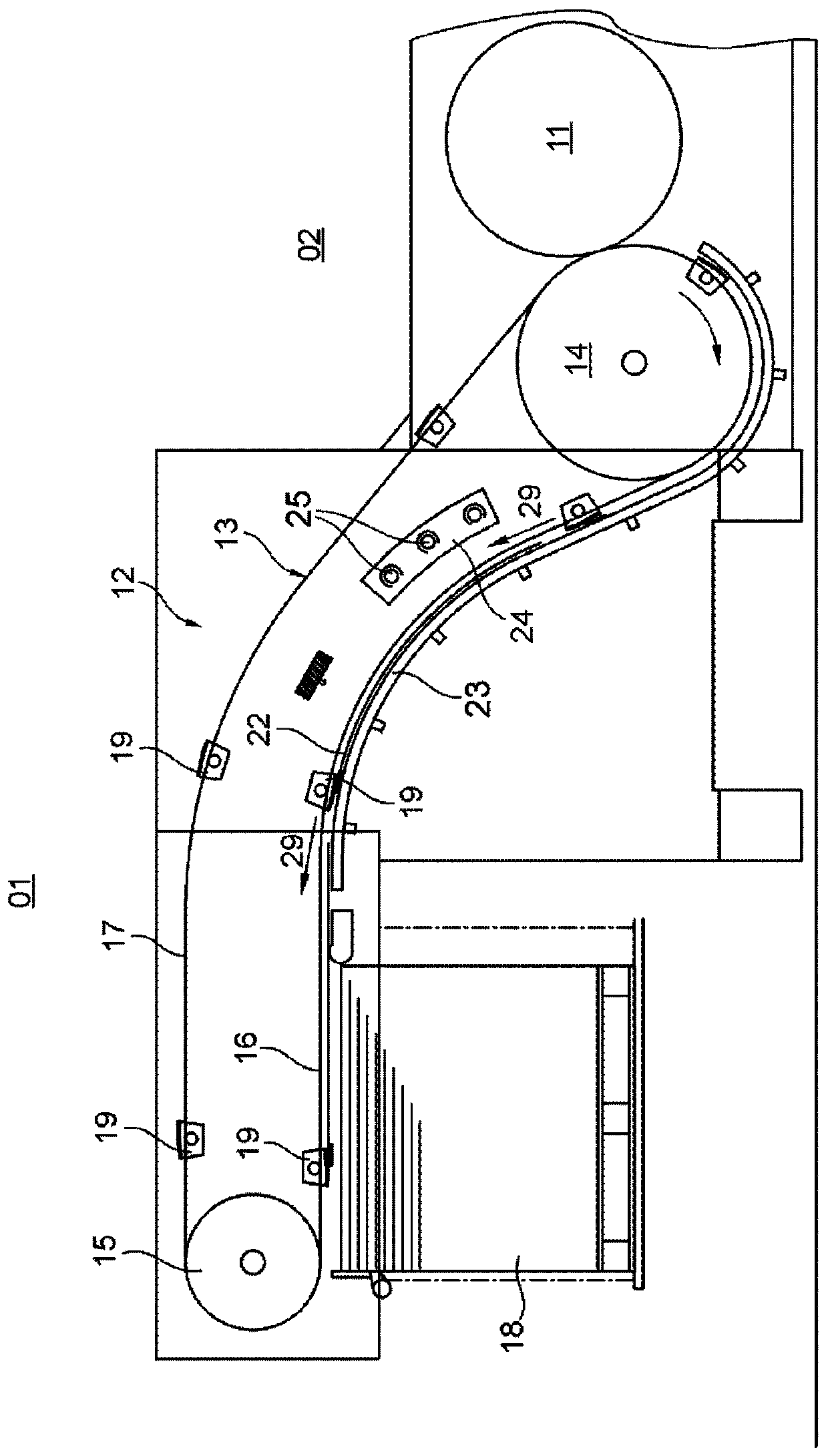

[0033] figure 1 Parts of the output unit 01 and the final printing unit 02 of a machine for processing sheet-fed paper, for example a sheet-fed printing press, are shown in side view, here preferably in an assembly and in-line configuration Form sheet-fed lithographic printing presses. The printing cylinder 11 of the printing unit 02 transfers the sheet 22 to the sheet of the output unit 01 after the last printing ink has been applied to the sheet 22 in contact with a blanket cylinder not shown. Sheet transport system 12. Alternatively, other devices, such as a varnishing device, can also transfer the individual sheets 22 to the output device 01 or the individual sheet transport system 12 . The sheet transport system 12 comprises two closed chains 13 deflected on sprockets 14 , 15 . The chain guides arranged on the side frames of the output device 01 guide the lower and upper return runs 16, 17 of the chain 13 respectively in a curved, first oblique climb from the sprocket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com