Geotechnical filling for use in cold area

A cold area, raw material technology, applied in the field of civil construction materials, can solve problems such as deformation damage, uneven settlement, road damage, etc., to increase integrity and corrosion resistance, reduce thermal conductivity and density, and high shear strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

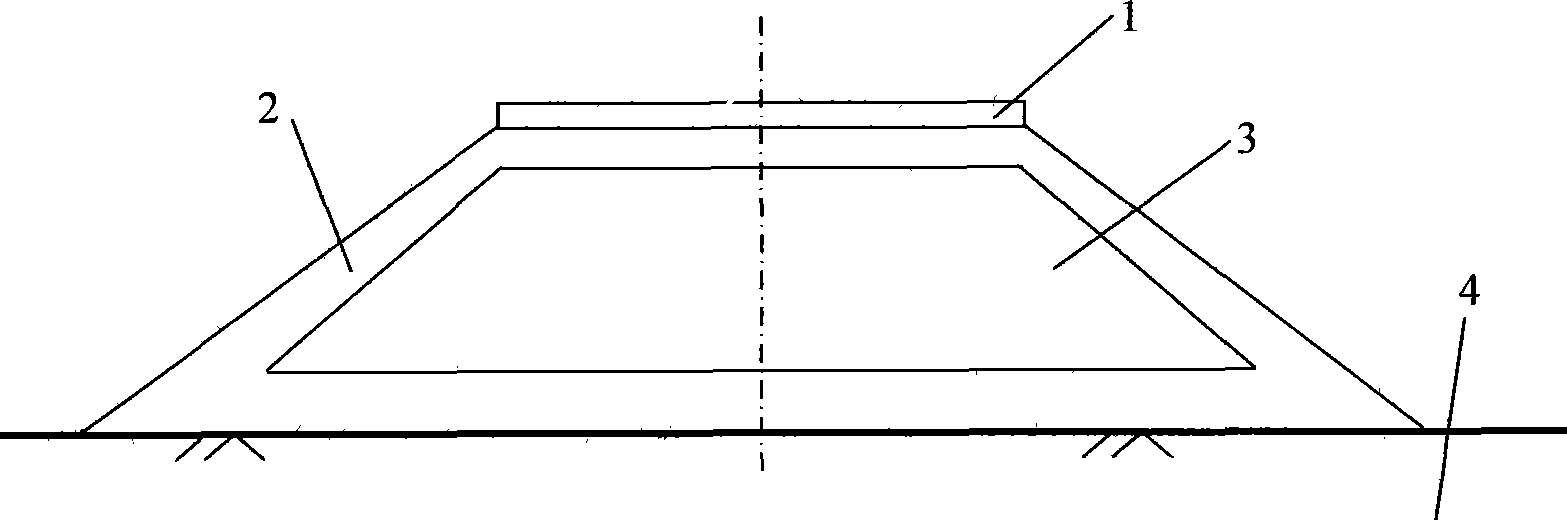

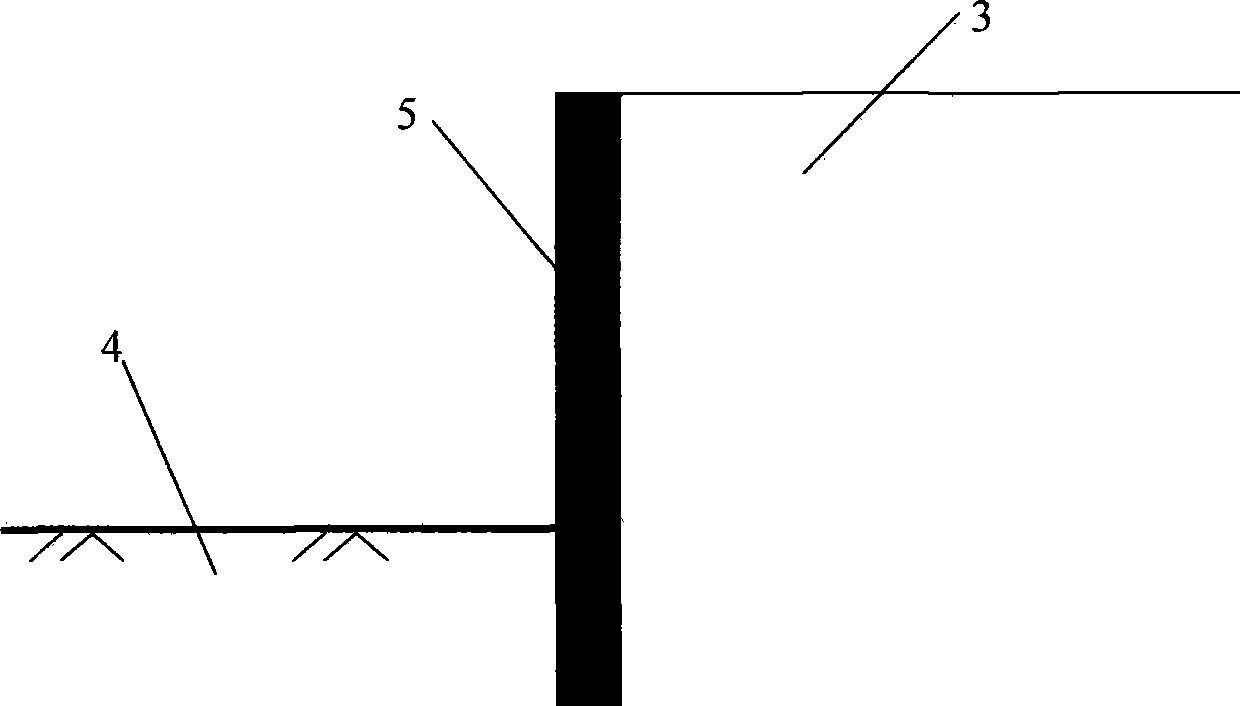

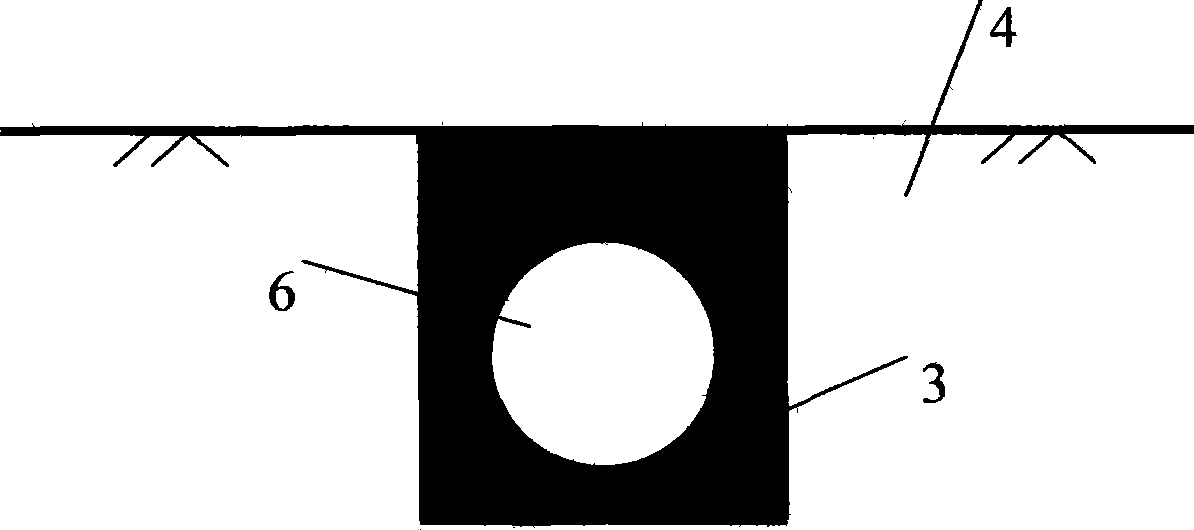

Image

Examples

Embodiment 1

[0038] A kind of geotechnical filler used in cold regions and the mass percentage of its proportion are as follows:

[0039] Waste foundry sand 60%

[0040] Fly Ash 17.8%

[0041] Cement 3.7%

[0042] Polystyrene particles 0.6%

[0043] Water 17.9%.

Embodiment 2

[0045] A kind of geotechnical filler used in cold regions and the mass percentage of its proportion are as follows:

[0046]Waste foundry sand 56.8%

[0047] Fly Ash 17%

[0048] Cement 8.8%

[0049] Polystyrene particles 0.4%

[0050] Water 17%.

Embodiment 3

[0052] A kind of geotechnical filler used in cold regions and the mass percentage of its proportion are as follows:

[0053] Waste foundry sand 56.4%

[0054] Fly Ash 16.9%

[0055] Cement 8.7%

[0056] Polystyrene Granules 1.0%

[0057] Water 17%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com