Treatment device and method for non-destructive disassembling the waste circuit board

A technology for waste circuit boards and processing equipment, which is applied in welding equipment, metal processing equipment, and solid waste removal. To solve problems such as ground sealing, to achieve the effect of light weight, fast disassembly and low power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

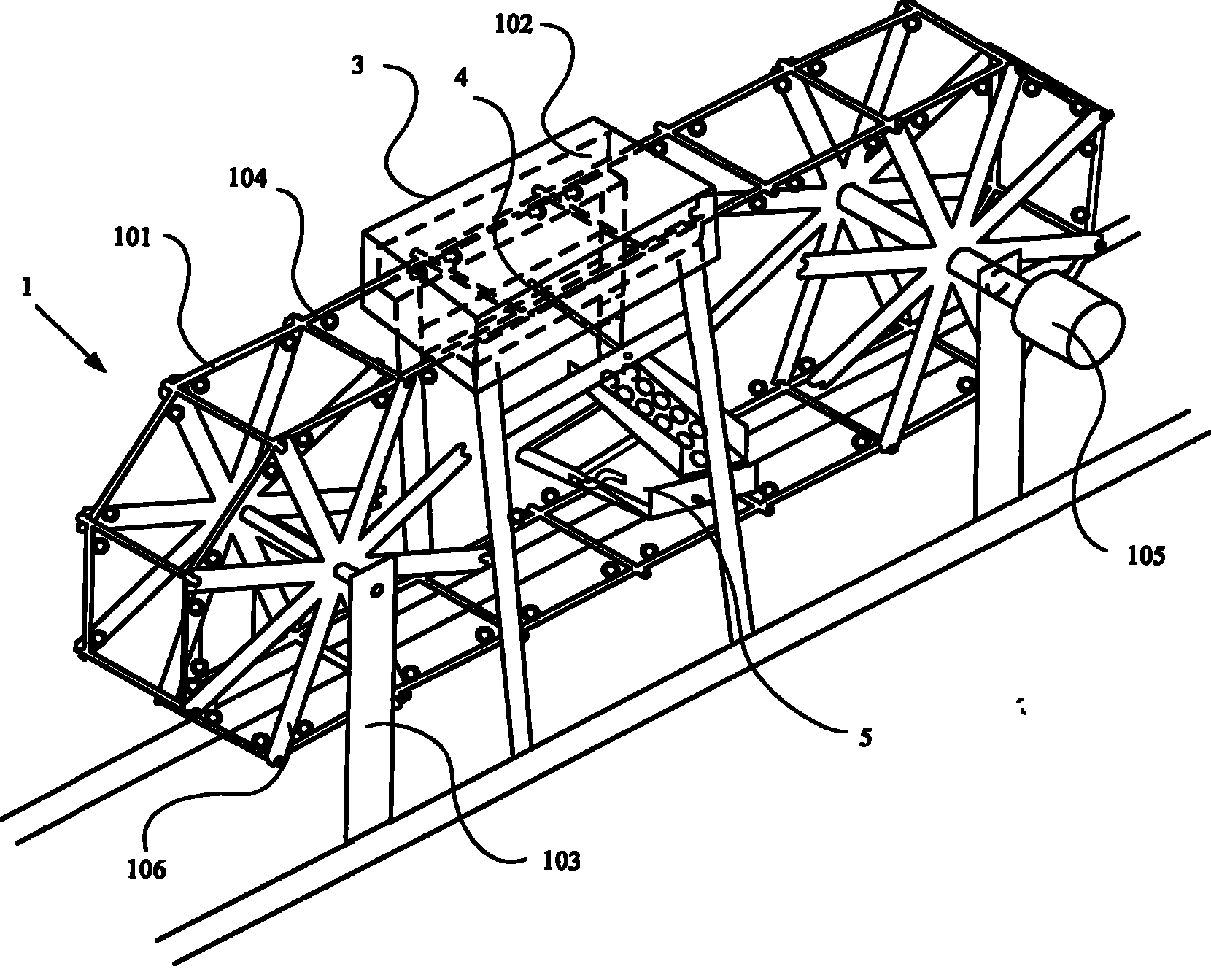

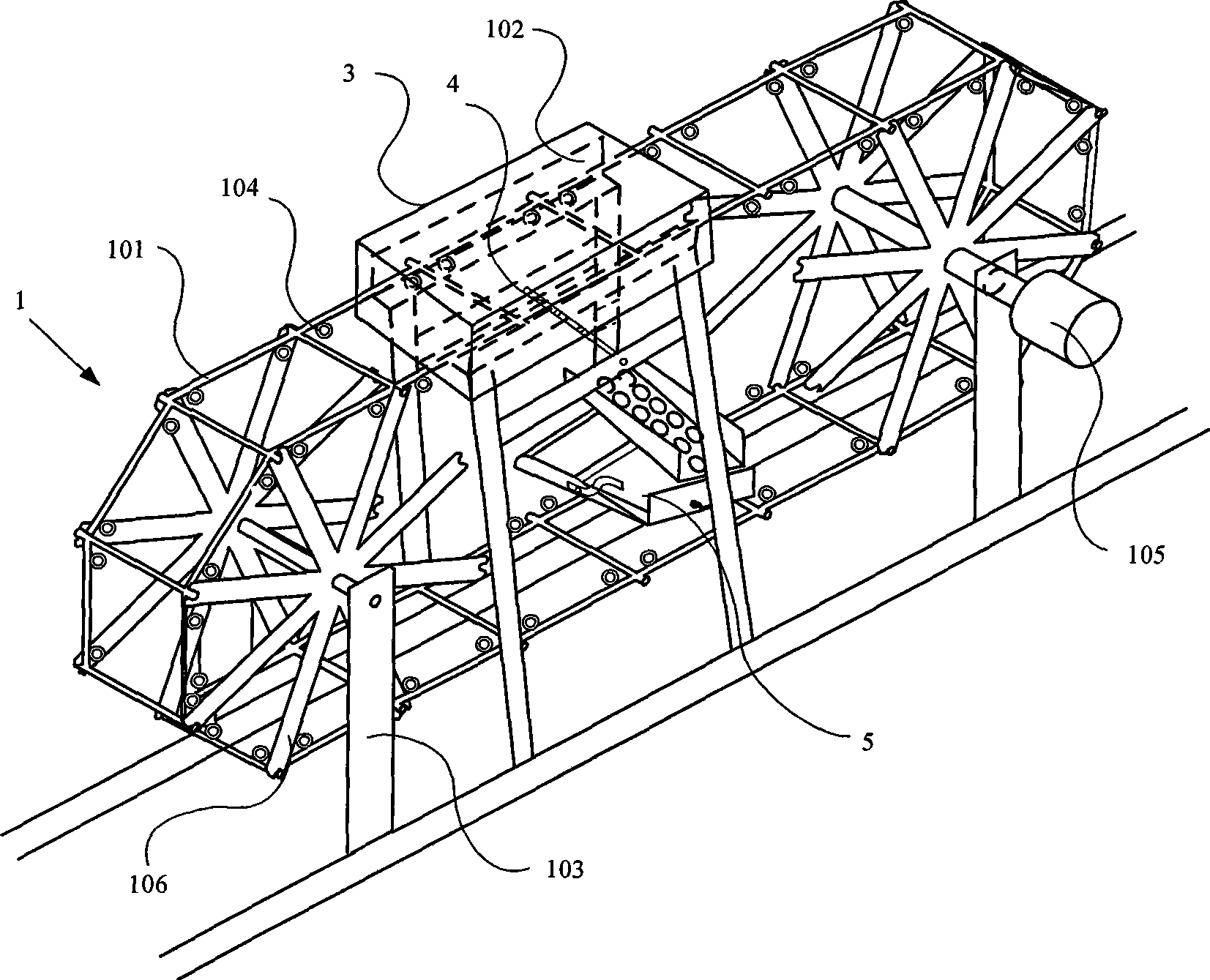

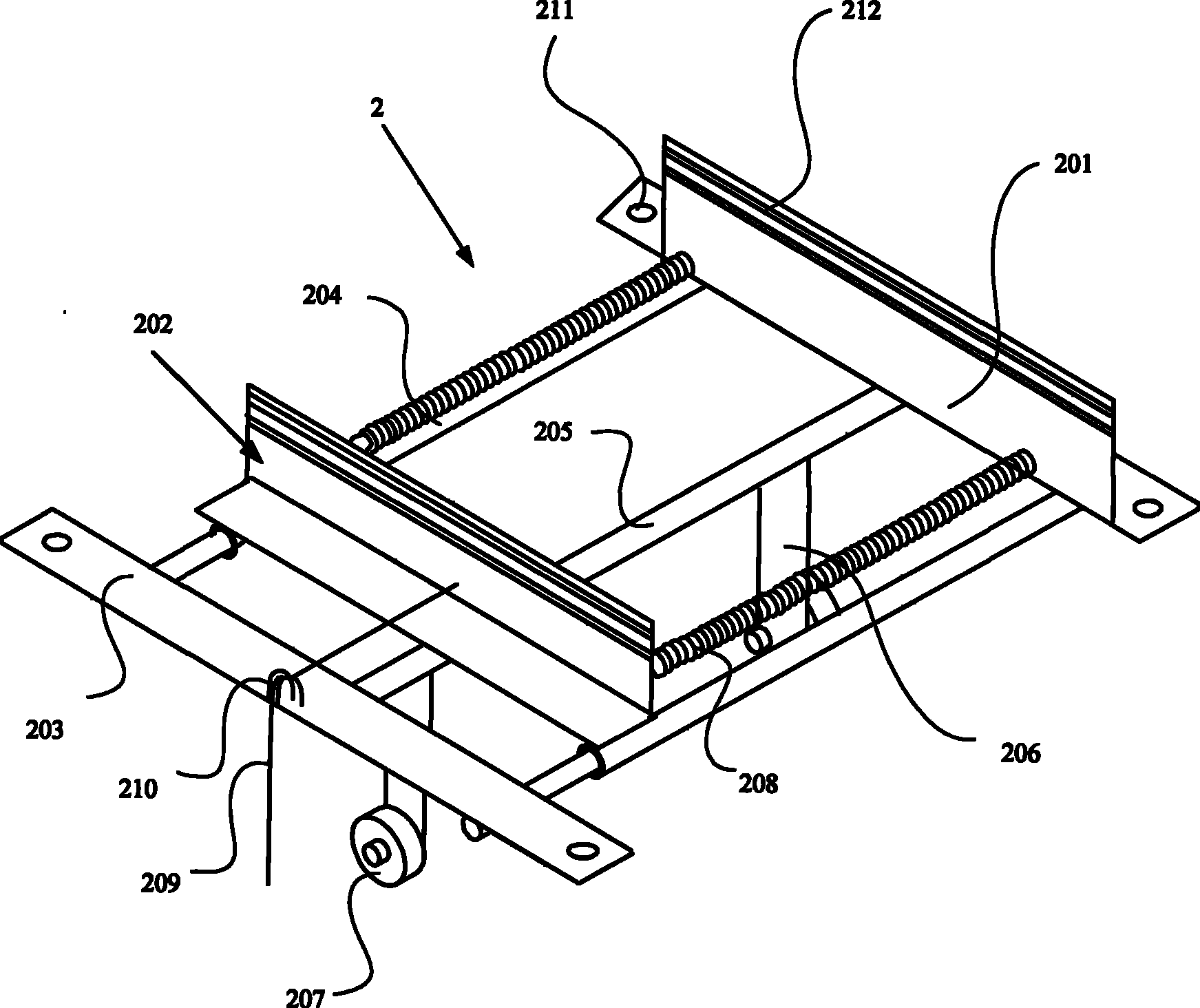

[0033] The invention provides a non-destructive disassembly processing equipment for waste circuit boards, which mainly consists of six parts: a conveying unit 1, a card loading and unloading unit 2, a heating and heat preservation unit 3, a vibration unit 4, a recovery unit 5, and a smoke removal unit.

[0034] As shown in Figure 1, conveying unit 1 comprises transmission chain 101, transmission wheel 106 and transmission motor 105, is meshing connection between transmission wheel 106 and transmission chain 101, and transmission wheel 106 is fixed on the ground by sprocket support seat 103, simultaneously One of the transmission wheels 106 is connected with a transmission motor 105, and the transmission motor 105 is used to drive the transmission wheel 106 to rotate, and then drives the transmission chain 101 to drive thereupon. A roller 104 is arranged belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com