A method for dismantling and recycling a square power battery cover plate

A power battery and recycling method technology, applied in battery recycling, recycling technology, waste collector recycling, etc., can solve problems such as cumbersome operation, separation of parts of different materials, and no universally used method for square power battery cover plates. Achieve the effect of low cost investment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

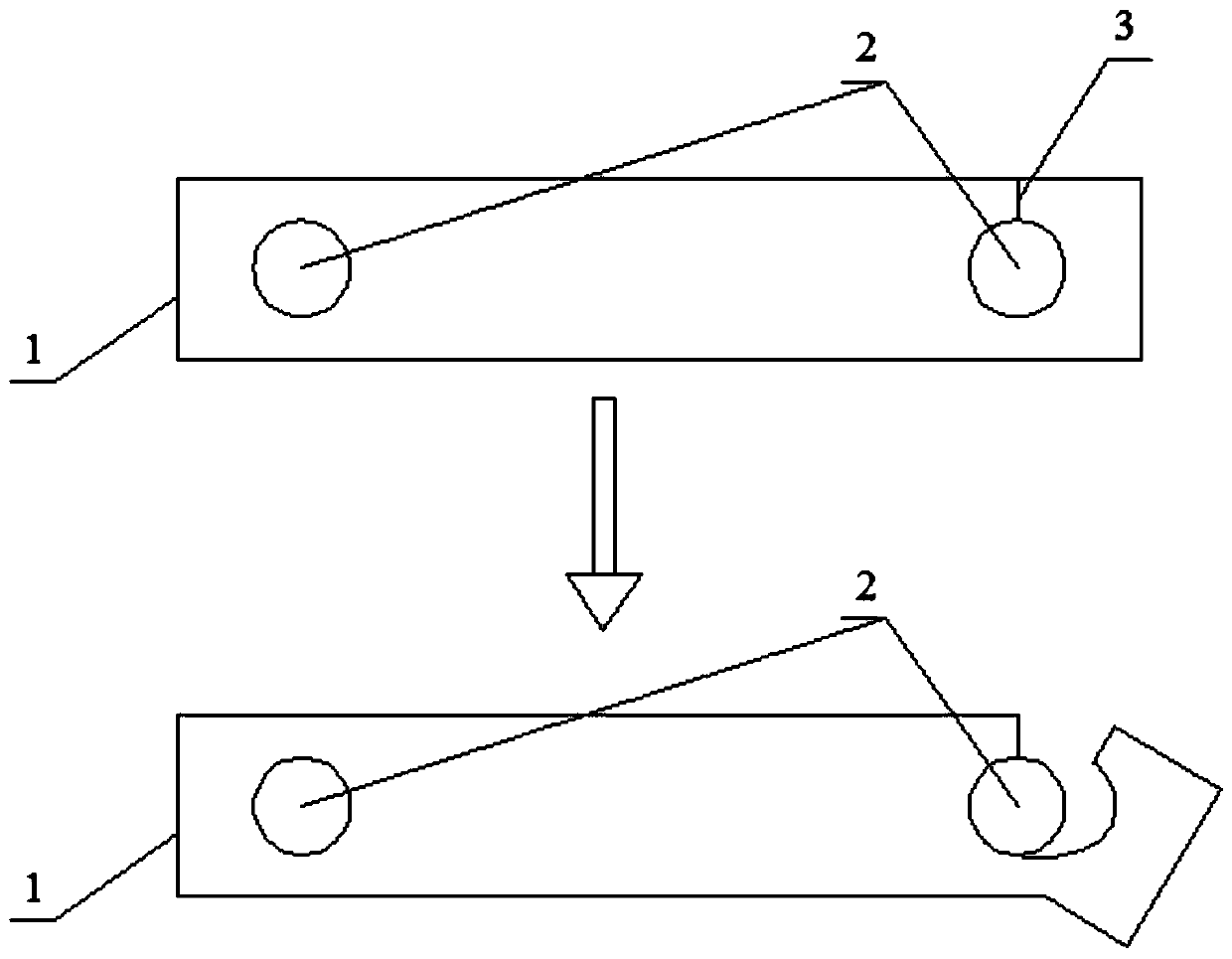

[0021] Such as figure 1 As shown in the figure, a method for dismantling and recycling the cover plate of a square power battery first uses a cutting tool to cut a slit on the cover plate on the outer periphery of the pole along the radial direction of the pole, the outer end of the incision extends to the outer edge of the cover plate, and the inner end of the incision Extend to the inner edge of the cover plate in contact with the pole; then use the clamp to clamp the cover plate, so that the cover plate rotates in the direction away from the cutout, and the cutout is opened accordingly. When it falls down, the plastic bracket under the cover is separated at the same time, which realizes the disassembly and recycling of the pole, the cover and the plastic bracket. Wherein, the battery cover is a cover disassembled from the battery, and the cutting tool is an impact knife.

Embodiment 2

[0023] Such as figure 1 As shown in the figure, a method for dismantling and recycling the cover plate of a square power battery first uses a cutting tool to cut a slit on the cover plate on the outer periphery of the pole along the radial direction of the pole, the outer end of the incision extends to the outer edge of the cover plate, and the inner end of the incision Extend to the inner edge of the cover plate in contact with the pole; then use the clamp to clamp the cover plate, so that the cover plate rotates in the direction away from the cutout, and the cutout is opened accordingly. When it falls down, the plastic bracket under the cover is separated at the same time, which realizes the disassembly and recycling of the pole, the cover and the plastic bracket. Wherein, the battery cover is a waste cover, and the cutting tool is an impact knife.

Embodiment 3

[0025] Such as figure 1 As shown in the figure, a method for dismantling and recycling the cover plate of a square power battery first uses a cutting tool to cut a slit on the cover plate on the outer periphery of the pole along the radial direction of the pole, the outer end of the incision extends to the outer edge of the cover plate, and the inner end of the incision Extend to the inner edge of the cover plate in contact with the pole; then use the clamp to clamp the cover plate, so that the cover plate rotates in the direction away from the cutout, and the cutout is opened accordingly. When it falls down, the plastic bracket under the cover is separated at the same time, which realizes the disassembly and recycling of the pole, the cover and the plastic bracket. Wherein, the battery cover is a waste cover, and the cutting tool is an impact knife.

[0026] The cover board should be dedusted and degreased before cutting. The specific operation is: soak the cover board in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com