Method for decomposing sodium phenolate using low CO2-content exhaust gas

A low content, waste gas technology, applied in the direction of chemical instruments and methods, preparation of organic compounds, alkali metal compounds, etc., can solve the problems of large sulfuric acid consumption, poor operating conditions, serious equipment corrosion, etc., to reduce CO2 emissions, no Bring environmental pollution and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

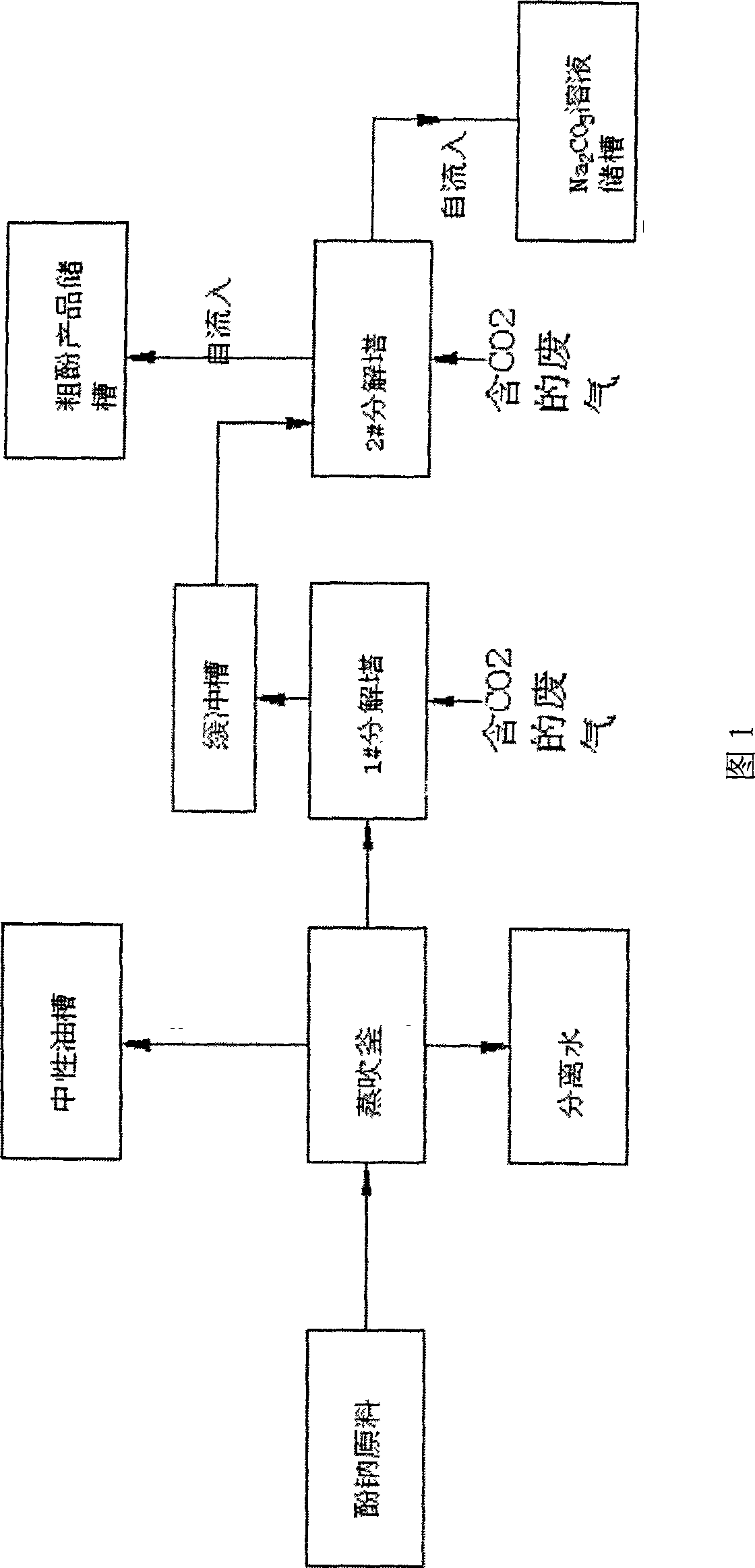

Image

Examples

Embodiment 1

[0012] Utilize low CO 2 Exhaust gas (CO 2 waste gas with a content of less than 12%) is cooled by a direct cooling cooling tower (existing equipment) to a water vapor dew point temperature of 40-60°C, water vapor and sundries in the waste gas are removed, and the waste gas is pumped to the decomposition tower by a fan. The flow rate of the waste gas is 3000m 3 / h; Sodium phenate is heated to 60°C with steam and then enters the decomposition tower with low content of CO 2 Exhaust gas contact, through the function of decomposition tower internals, realizes heat transfer and mass transfer, and decomposes sodium phenate into crude phenol and soda ash. The internal part of the decomposition tower is high-efficiency packing—real material of metal Bowen board, and a collector ring is installed in the decomposition tower to make the gas and liquid fully contact. The decomposition tower used is about 1 / 3 higher than the ordinary decomposition tower, and the crude phenol and soda ash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com