Device and method for manufacturing solar grade polysilicon

A solar-grade and device-manufacturing technology, which is applied in the field of manufacturing solar-grade polysilicon devices and solar-grade polysilicon devices, can solve the problems of numerous process steps, low production efficiency, expensive equipment, and the like, so as to reduce energy consumption and increase Improved surface area and purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

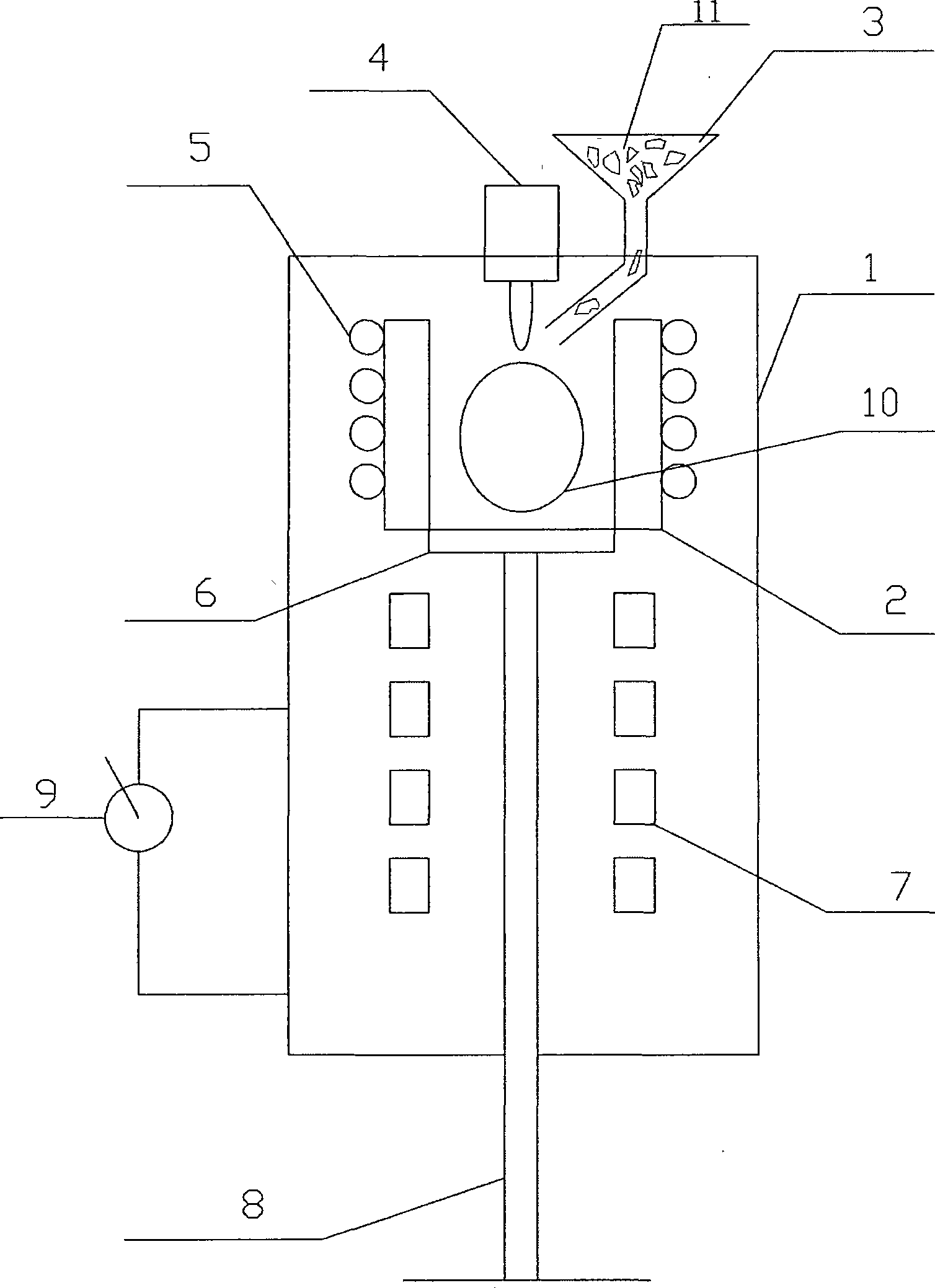

[0026] Adjust the directional solidification mechanism 8 to raise the water-cooled chassis 6 to the bottom of the suspension melting crucible 2, and add 3 kg of industrial silicon material 11 into the suspension melting crucible 2. Turn on the vacuum system 9 to evacuate the vacuum chamber 1 to 10 -2 Pa. Turn on the induction plasma generator 4 and the induction coil 5, adjust the power of the induction plasma generator 4 to 60 kilowatts, and adjust the power of the induction coil 5 to 150 kilowatts. First, the silicon material is gradually melted into a silicon liquid under the high temperature of the plasma, and then the induced magnetic field generates an induced current in the silicon liquid. After the industrial silicon material is completely melted and suspended, water vapor (flow rate: 50 psig) is introduced. Add silicon material into the crucible at a rate of 100 g / min until the total melting amount reaches 10 kg. Then upwardly lift the water-cooled chassis 6 until ...

Embodiment 2

[0028] Adjust the directional solidification mechanism 8 to raise the water-cooled chassis 6 to the bottom of the suspension melting crucible 2, and add 2 kg of industrial silicon material 11 into the suspension melting crucible 2. Turn on the vacuum system 9 to evacuate the vacuum chamber 1 to 10 -2 Pa. Turn on the induction plasma generator 4 and the induction coil 5, adjust the power of the induction plasma generator 4 to 50 kilowatts, and adjust the power of the induction coil 5 to 120 kilowatts. First, the silicon material is gradually melted into a silicon liquid under the high temperature of the plasma, and then the induced magnetic field generates an induced current in the silicon liquid. After the industrial silicon material is completely melted and completely suspended, liquid water (flow rate: 10ml / min) is introduced. Add silicon material into the crucible at a rate of 100 g / min until the total melting amount reaches 10 kg. Then then upwardly lift the water-coole...

Embodiment 3

[0030] Adjust the directional solidification mechanism 8 to lift the water-cooled chassis 6 to the bottom of the suspension melting crucible 2, and add 5 kg of industrial silicon material 11 into the suspension melting crucible 2. Turn on the vacuum system 9 to evacuate the vacuum chamber 1 to 10 -2 Pa. Turn on the induction plasma generator 4 and the induction coil 5, adjust the power of the induction plasma generator 4 to 80 kilowatts, and adjust the power of the induction coil 5 to 170 kilowatts. First, the silicon material is gradually melted into a silicon liquid under the high temperature of the plasma, and then the induced magnetic field generates an induced current in the silicon liquid. After the industrial silicon material is completely melted and completely suspended, HCl gas (flow rate: 50 psig) is introduced. Add silicon material into the crucible at a rate of 150 g / min until the total melting amount reaches 10 kg. Then then upwardly lift the water-cooled chass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com