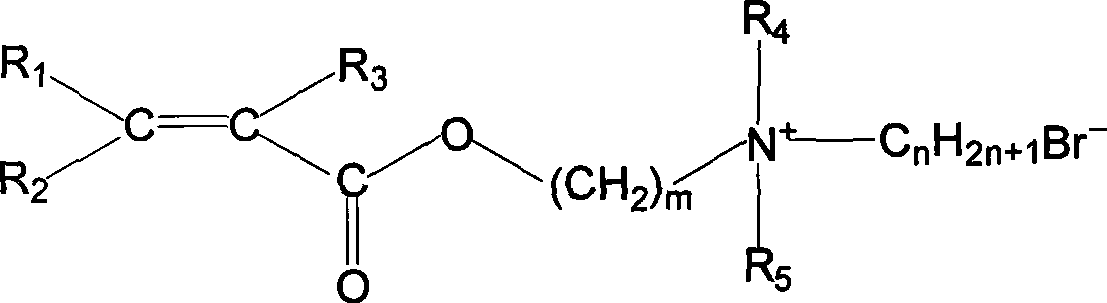

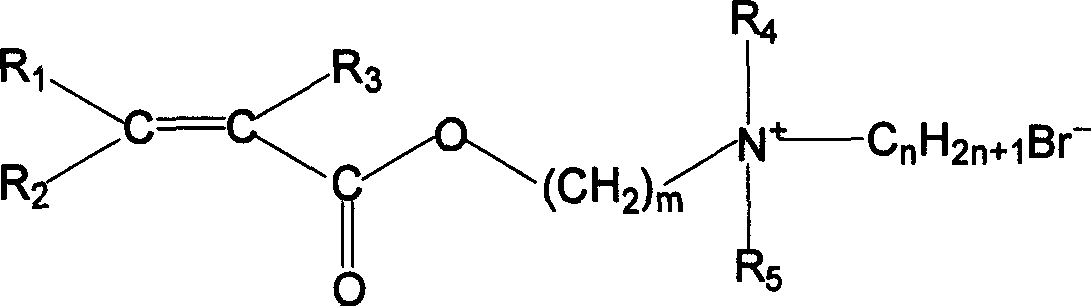

Method for preparing non-ionic hydrophobic association polymerization water-soluble polymer from reverse micro emulsion

A water-soluble polymer and hydrophobic association technology, which is applied in the field of non-ionic hydrophobic association water-soluble polymers and their synthesis, can solve the problems of product molecular chain damage, performance degradation, asymmetric distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the reaction vessel, add 80g of white oil and 40g of surfactant, control the HLB value of the surfactant mixture between 9.2, control the temperature at 40°C, stir at 800rpm, and stir for 1.5h; mix acrylamide according to the amount (Monomer A), dodecyl dimethyl (acryloxyethyl) ammonium bromide (monomer B) is formulated into an aqueous solution, the solution concentration is between 55 wt% (the molar ratio of A and B is 99:1 ). Then, under the condition of stirring again, the aqueous monomer solution was slowly added dropwise, and the stirring was continued for 5 hours, and the temperature of the solution was controlled between 40°C. Continue to stir, control the stirring speed between 300rpm, pass high-purity nitrogen for 30 minutes, add 0.15g of water-soluble free radical initiator V50, and continue to pass nitrogen for 5 hours to obtain a transparent polymer microlatex with bluish light.

Embodiment 2

[0023] In the reaction vessel, add 80g of white oil and 40g of surfactant, control the HLB value of the surfactant mixture between 9.2, control the temperature at 40°C, stir at 800rpm, and stir for 1.5h; mix acrylamide according to the amount (Monomer A), dodecyl dimethyl (acryloxyethyl) ammonium bromide (monomer B) is formulated into an aqueous solution, the solution concentration is between 55 wt% (the molar ratio of A and B is 99:1 ). Then, under the condition of stirring again, the aqueous monomer solution was slowly added dropwise, and the stirring was continued for 5 hours, and the temperature of the solution was controlled between 40°C. Continue to stir, control the stirring speed between 300rpm, pass high-purity nitrogen for 30 minutes, add 0.70 g of water-soluble free radical initiator V50, and continue to pass nitrogen for 5 hours to obtain transparent polymer microlatex with bluish light.

Embodiment 3

[0025] In the reaction vessel, add 80g of white oil and 40g of surfactant, control the HLB value of the surfactant mixture between 9.2, control the temperature at 40°C, stir at 800rpm, and stir for 1.5h; mix acrylamide according to the amount (Monomer A), dodecyl dimethyl (acryloxyethyl) ammonium bromide (monomer B) is formulated into an aqueous solution, the solution concentration is between 55 wt% (the molar ratio of A and B is 99:1 ). Then, under the condition of stirring again, the aqueous monomer solution was slowly added dropwise, and the stirring was continued for 5 hours, and the temperature of the solution was controlled between 40°C. Continue to stir, control the stirring speed between 300rpm, pass high-purity nitrogen for 30 minutes, add 0.50 g of water-soluble free radical initiator V50, and continue to pass nitrogen for 5 hours to obtain a transparent polymer microlatex with bluish light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com