3,3'-dichlorobenzidine hydrochloride waste water reclaiming method and apparatus thereof

A technology of dichlorobenzidine hydrochloride and treatment method, which is applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. High economic value, low treatment cost, and the effect of eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

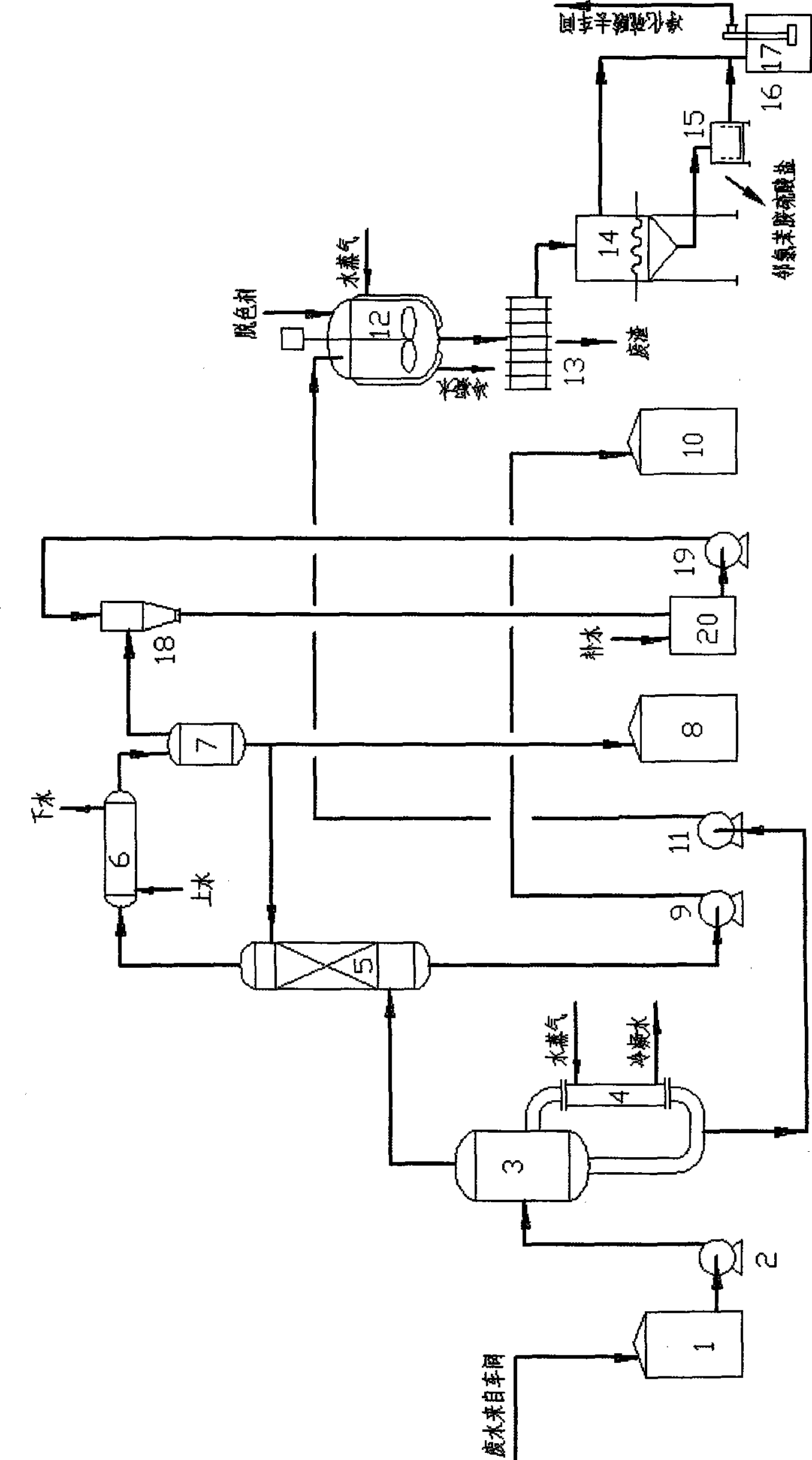

Image

Examples

Embodiment 1

[0051] 500mL of 3,3'-dichlorobenzidine hydrochloride production mother liquor wastewater containing 8% (mass fraction) of hydrochloric acid, 24% (mass fraction) of sulfuric acid and about 1.5% (mass fraction) of organic matter was added in a three-necked flask of 1000mL , evacuate to 0.09MPa, heat the electric heating mantle to boiling, and condense the evaporated HCl and water with a condenser tube. When the sulfuric acid was concentrated to about 50% (mass fraction), the temperature was about 69°C, and the heating was stopped. At this time, the condensate contained about 14% (mass fraction) of hydrochloric acid average concentration. If the condensate is received in sections, hydrochloric acid with a concentration of 17% (mass fraction) can be obtained. Add 9 g of activated carbon into the three-necked flask, and decolorize it by slight boiling for 1 h. Filtrate while hot to remove activated carbon to obtain almost colorless sulfuric acid concentrate. The filtrate was plac...

Embodiment 2

[0053] Use a pump to add 3,3'-dichlorobenzidine hydrochloride production mother liquor wastewater containing 8% (mass fraction) of hydrochloric acid, 24% (mass fraction) of sulfuric acid and about 1.5% (mass fraction) of organic matter to the external heating natural circulation In the evaporator, vacuumize to 0.09MPa, heat to boiling with saturated water vapor, and continuously add waste water to keep the liquid level in the evaporator constant. The steamed HCl and water enter the bottom of the rectification tower with packing, adjust the reflux ratio to 1.2, and obtain hydrochloric acid with an average content of about 20% (mass fraction) at the bottom of the tower, and the water vapor at the top of the tower enters the condensation tube to condense, and the condensate hydrochloric acid The average content is about 4% (mass fraction). When the sulfuric acid concentration reaches about 50% (mass fraction), stop heating, pump the concentrated waste water into the decolorization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com