Method for fast choosing technological condition for preparing nanometer medicine-loading fibre felt by electro spinning

A technology of process conditions and nano-drug loading, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of high cost, complicated processing, inconvenience, etc., and achieve short time consumption, simple operation, and controlled release performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Preparation of drug-loaded fiber mats using different solvents to prepare PAN spinning solutions by electrospinning

[0025] The drug-loaded fiber spinning solution was prepared according to the following steps: 10g of acyclovir was dissolved in 1000mL of dimethylacetamide (DMAc) in a water bath at 60°C; then 90g of polyacrylonitrile (PAN) fine powder was added Wherein, it was swelled for 24 hours under stirring at 250 rpm and a water bath at 60° C.; cooled to room temperature to prepare for spinning.

[0026] Prepare the spinning stock solution of acyclovir of dimethyl sulfoxide (DMSO) and dimethylformamide (DMF) in the same steps and ratio.

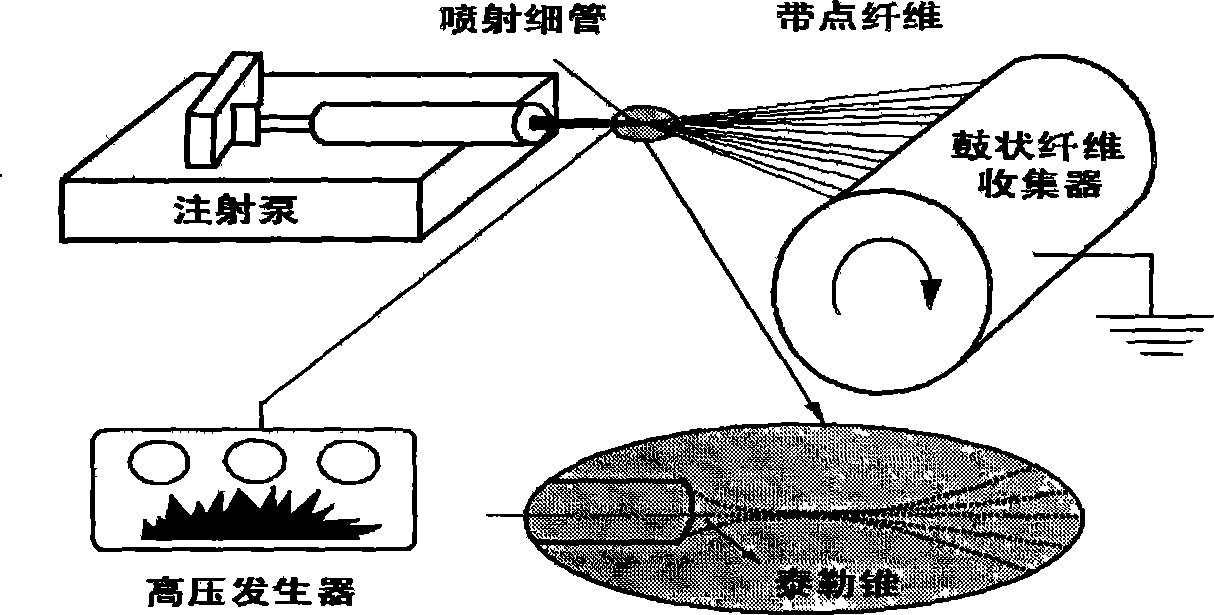

[0027] Pour the prepared solution into the solution reservoir (5mL syringe), use the flattened No. 6 injection needle as the capillary for spraying thin stream, connect the positive electrode of the high-voltage power supply, and connect the negative electrode to the aluminum foil fiber receiving plate with the glass s...

Embodiment 2

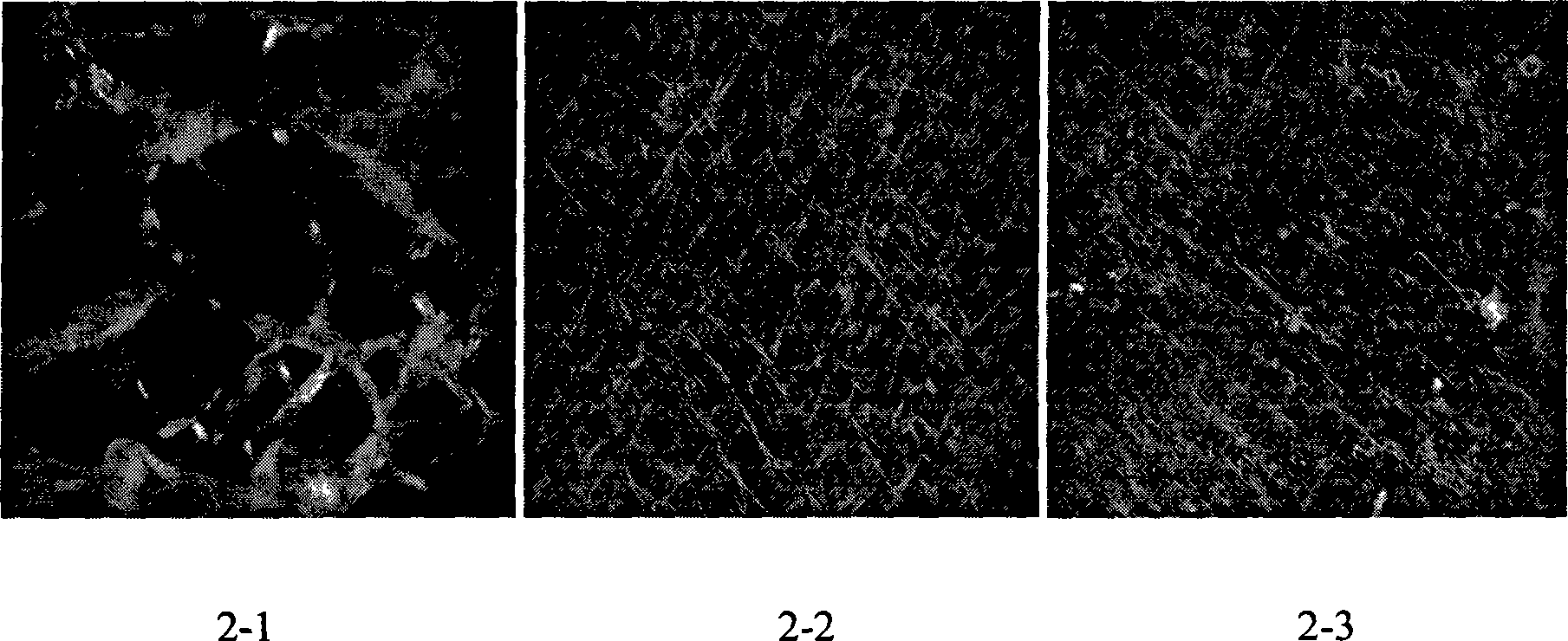

[0028] Embodiment 2: Observation of PAN drug-loaded fiber mat under different solvents by polarizing microscope

[0029] Carefully remove the downloaded glass slide, cover it with a cover glass, and fix it under a polarizing microscope. The polarizer and the analyzer are orthogonally interleaved, and observed under high magnification (objective lens 63 times × shooting magnification 16 times), and use Recorded by Canon digital cameras. The result is as figure 2 As shown, the spinning dope prepared by DMSO has a high volatilization point, which leads to serious adhesion phenomenon. Due to the low solubility of the drug in DMF and fast volatilization, although the diameter of the spun fiber is small, some crystals are separated out. , It is easy to cause the initial burst release effect of drug release, so it is better to use DMAc in the preparation of PAN drug-loaded fibers of acyclovir. Wherein, when DMAc solvent is used, the diameter range of the PAN drug-loaded fiber of a...

Embodiment 3

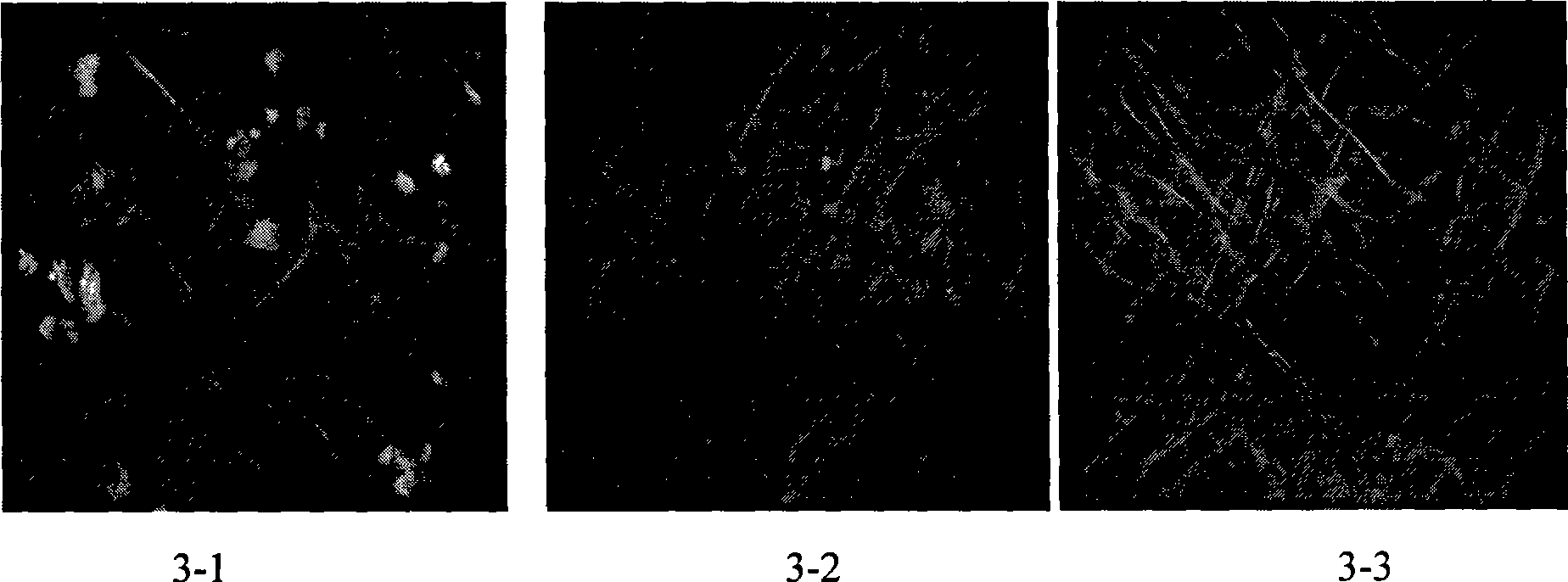

[0030] Example 3: Preparation of Eudragit III drug-loaded fibers with different ibuprofen concentrations by electrospinning and polarized light observation

[0031] Dissolve 5, 10, and 20 g of ibuprofen in 500 mL of methanol at room temperature, respectively; then add 100 g of Eudragit III into it, swell for 2 hours under stirring at 250 rpm, and then ultrasonically degas.

[0032] Pour the prepared solution into the solution reservoir (5mL syringe), use the flattened No. 6 injection needle as the capillary for spraying thin stream, connect the positive electrode of the high-voltage power supply, and connect the negative electrode to the aluminum foil fiber receiving plate with the glass slide, and the solution The ejection volume was controlled by a micro-syringe pump, and electrospinning was carried out for 10 minutes under the following conditions: the flow rate was 1.0 mL h -1 , the distance between the receiving plate and the spinneret is 15cm, the voltage is 15kV, the am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com