Preparation method of pH-sensitive type hydrogel

A technology of sensitive hydrogel and gelatin, applied in the field of preparation of pH-sensitive hydrogel, can solve the problems of too fast gel formation of sodium alginate, difficult shape control, uneven texture of hydrogel, etc. Time, good shape, uniform and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

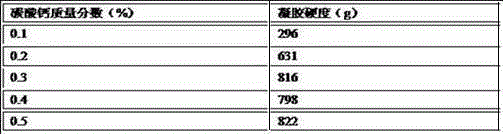

[0020] Calcium carbonate addition test—the mass fraction of calcium carbonate affects the hardness of pH-sensitive hydrogels. The dissolution temperature was 60°C, the ultrasonic power was 400W, the mass fraction of gluconolactone was 0.6%, and the gelation temperature was 4°C.

[0021] Table 1 Effect of calcium carbonate mass fraction on pH-sensitive hydrogel hardness

[0022]

[0023] It can be seen from Table 1 that when the mass fraction of calcium carbonate is lower than 0.3%, the hardness of the pH-sensitive hydrogel increases with the increase of the mass fraction of calcium carbonate. When the mass fraction of calcium carbonate is higher than 0.3%, the gel hardness does not change much. This shows that a certain mass fraction of calcium carbonate is beneficial to increase the hardness of the pH-sensitive hydrogel.

Embodiment 2

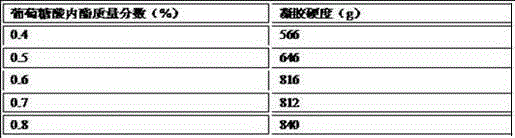

[0025] Gluconolactone addition test—the mass fraction of gluconolactone affects the release rate of calcium ions, thereby affecting the hardness of the pH-sensitive hydrogel. The dissolution temperature is 60°C, the ultrasonic power is 400W, the mass fraction of calcium carbonate is 0.3%, and the gelling temperature is 4°C.

[0026] Table 2 Effect of mass fraction of gluconolactone on hardness of pH-sensitive hydrogel

[0027]

[0028] It can be seen from Table 2 that when the mass fraction of gluconolactone is lower than 0.6%, the hardness of the pH-sensitive hydrogel increases with the increase of the mass fraction of calcium carbonate. When the mass fraction of gluconolactone was higher than 0.6%, the hardness of the gel did not change much. This shows that a certain mass fraction of gluconolactone is beneficial to increase the hardness of the pH-sensitive hydrogel.

Embodiment 3

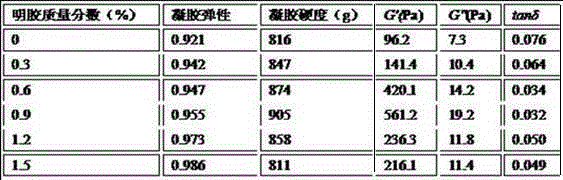

[0030] Gelatin addition test—the mass fraction of gelatin affects the elasticity and hardness of pH-sensitive hydrogels. The structural stability of the pH-sensitive hydrogel was evaluated by measuring the storage modulus (G'), loss modulus (G"), and loss factor (tanδ). The dissolution temperature was 60°C, the ultrasonic power was 400W, and carbonic acid The amount of calcium added was 0.3%, the mass fraction of gluconolactone was 0.6%, the gelation temperature was 4°C, and the oscillation frequency was 0.1Hz.

[0031] Table 3 Effect of gelatin mass fraction on the elasticity and hardness of pH-sensitive hydrogels

[0032]

[0033] It can be seen from Table 3 that with the increase of the gelatin mass fraction, the gel elasticity shows an upward trend, and the gel hardness, G', G", and tanδ first increase and then decrease. When the gelatin content is 0.9%, the gel elasticity reaches 0.955 , the gel hardness reached 905g, G' and G" reached the maximum value respectively, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com