Continuous flow cell electric amalgamation chip based on silicon structure on insulator

A silicon-on-insulator, electrofusion technology is applied in the field of biological cell electrofusion devices, which can solve the problems of corrosion resistance, anti-oxidation ability, weak precise control of cells, easy to be corroded, etc., so as to improve the efficiency of cell fusion, The effect of improving biocompatibility and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

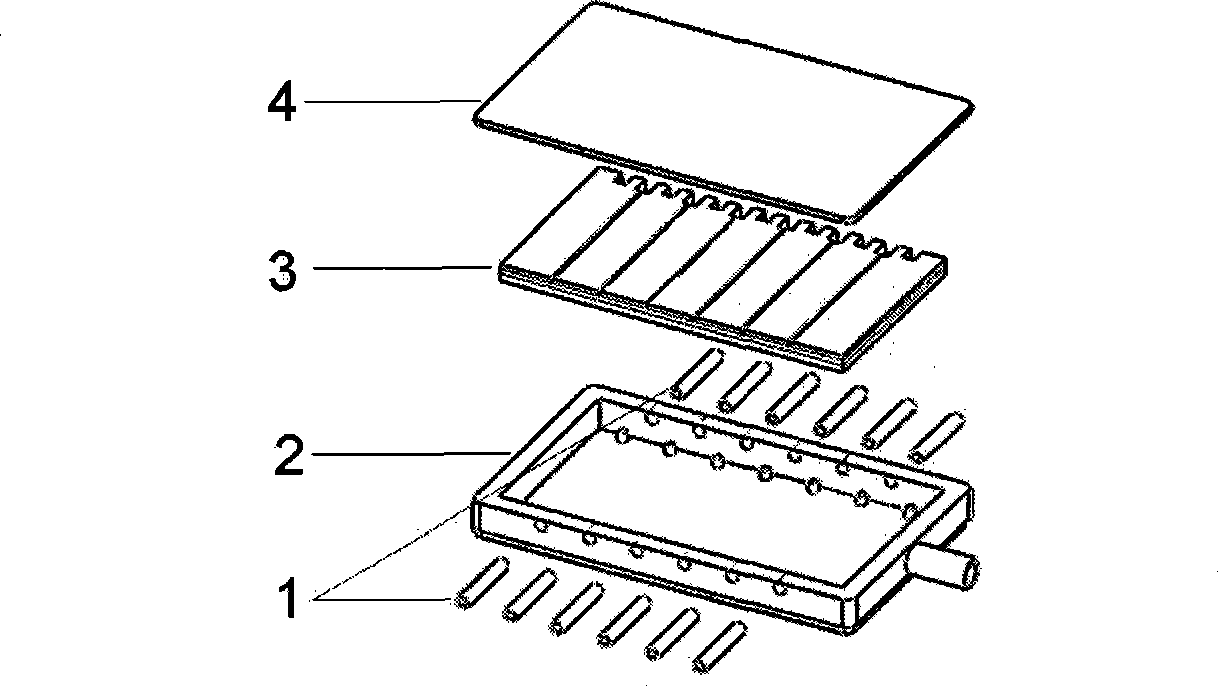

[0036] see figure 1 and figure 2 The cell electrofusion chip consists of a shell 2, a microelectrode array chip 3 fixed in the shell, a sample inlet and outlet conduit 1 connecting the inside and outside of the shell, and a silicon glass sheet 4 packaged on the surface of the shell.

[0037] For the structure of the housing see image 3 , image 3 A is a perspective view of the casing. image 3 B is the top view of the shell, image 3 C is the right side view of the case, image 3 D is the front view of the shell, the center of the shell 2 is an inner cavity 5 for accommodating the chip, the bottom has pins 9 corresponding to the microelectrode array of the chip, and the two side walls have a sample inlet 7 and a sample outlet 8, and in the shell 2. A cylinder 6 is arranged on the outside to facilitate the removal of the whole device.

[0038] For the structure of the microelectrode array chip see Figure 4 A. Figure 4 B and Figure 4 C, the microelectrode array chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com