Composite coating for high-temperature container for metal melting and method for making same

A high-temperature container and metal smelting technology, which is applied in the direction of metal material coating process, metal layered products, chemical instruments and methods, etc., can solve the problems of uneven thickness of silicon carbide layer and reduce the strength of the container, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

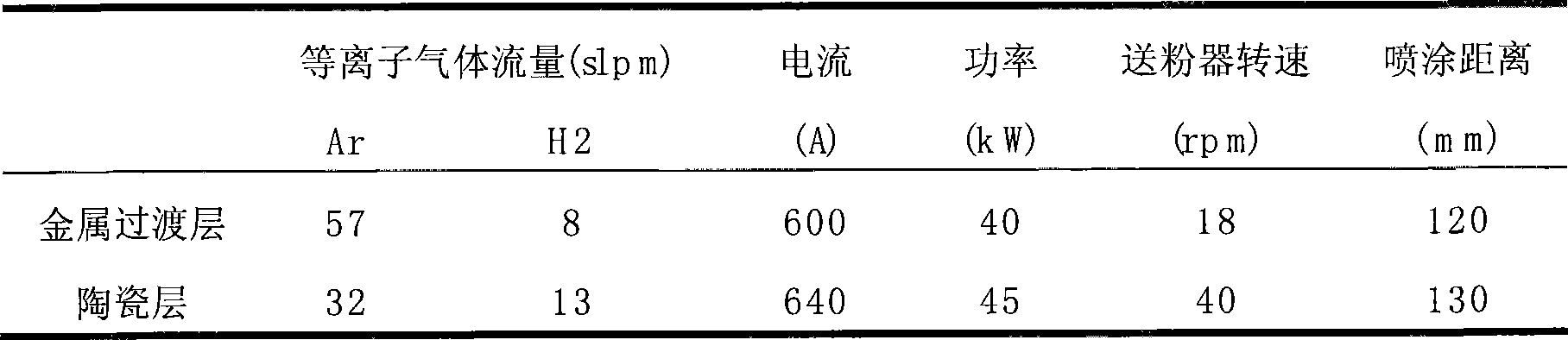

[0034] A single-layer 10μm-thick tungsten coating and a single-layer 0.25mm-thick yttrium oxide coating were prepared on the surface of a Φ300mm×Φ284mm×300mm graphite component with a wall thickness of 10mm. After 10 hours of use at 1400°C, the coating is intact, such as figure 1 shown. The spraying process parameters are shown in Table 1.

Embodiment 2

[0036] Prepare two layers of 10μm thick tungsten coating and a single layer of 0.25mm thick yttrium oxide coating on the surface of the stainless steel substrate, and use 20MW / m 2 After 400-600 times of irradiation, the coating is intact without cracking or peeling off. The spraying process parameters are shown in Table 2.

Embodiment 3

[0038] A single layer of 10 μm thick tungsten coating, a single layer of 10 μm thick molybdenum coating and two layers of 0.15 mm calcium zirconate coating were prepared on the surface of the stainless steel substrate, and no cracking and peeling occurred. The spraying process parameters are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com