Super-macromolecule polyethylene rope and preparation technology thereof

A technology of ultra-high molecular weight and preparation technology, applied in the field of ultra-high molecular weight polyethylene rope and its preparation technology, can solve the problems that ordinary chemical fiber cables do not have corrosion resistance, fatigue resistance, anti-ultraviolet and cable insulation, etc., and achieve light weight and structure Reasonable, good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

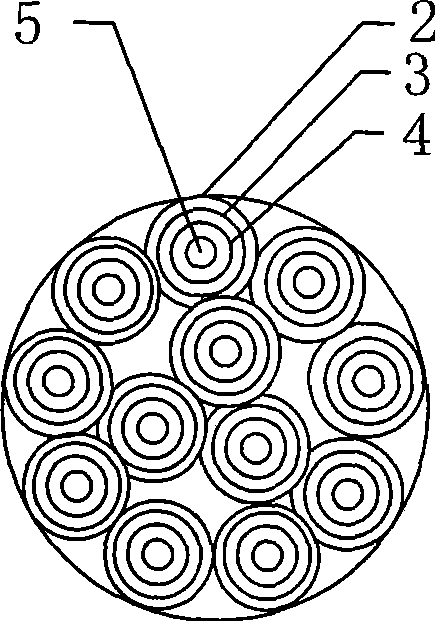

[0017] Such as Figure 1-2 As shown, a kind of ultra-high molecular weight polyethylene rope includes twelve strands 1 braided into one, wherein six strands 1 are left twisted strands, and six strands 1 are right twisted strands; said rope strands 1 include twisted strands The outer layer 2, the middle layer 3, the inner layer 4, and the core layer 5 are twisted lines formed together; the twisted lines are ultra-high molecular weight polyethylene fiber twisted lines, and the twisted lines are twisted according to the diameter of the rope.

[0018] The ultra-high molecular weight polyethylene rope preparation process of the present invention comprises the following steps:

[0019] 1) Selection of raw materials: The selected raw materials are ultra-high molecular weight polyethylene fibers (Futai fibers), the deviation of fiber density shall not be greater than 2.5%, the breaking strength shall be greater than 30cn / dtex, and the surface of the fibers shall be smooth and clean. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com