Heat treatment method of steel belt for packages and steel belt for packages

A heat treatment method and packaging technology, applied in the field of packaging steel strips, can solve the problems of inability to break through the tensile strength of packaging steel strips, small elongation after breaking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A carbon-manganese steel containing the following chemical composition is selected: C: 0.29%, Si: 0.24%, Mn: 1.33%, P: 0.015%, S: 0.007%, and the balance is Fe, and the percentages are weight percentages.

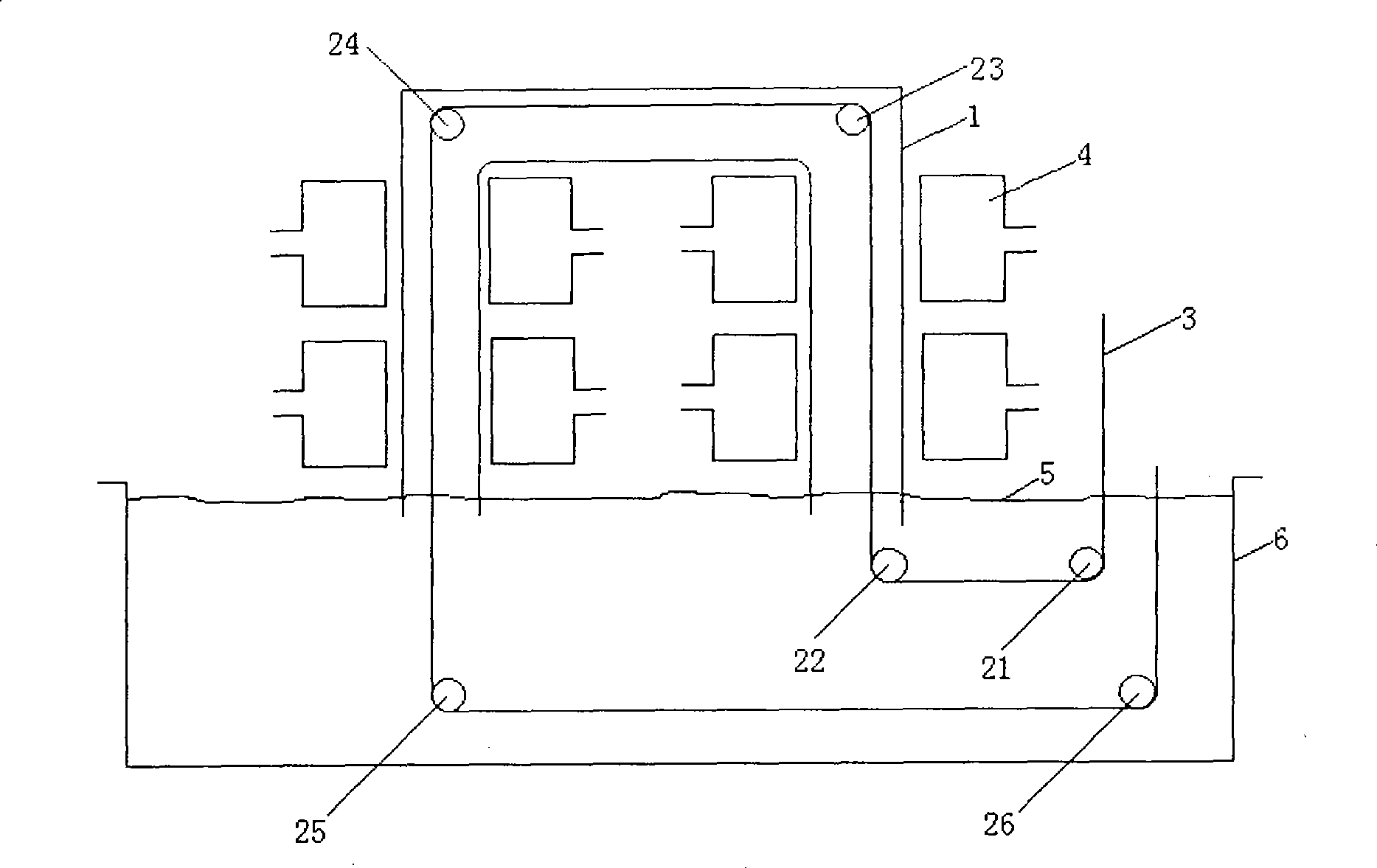

[0046] The above-mentioned carbon-manganese steel hot-rolled plate with a thickness of 2.0mm is selected as a raw material, and is pickled and cold-rolled into a steel strip of 0.9×199mm. The mechanical properties after cold-rolling are: tensile strength is 975MPa, and elongation is 6%. Then enter the equipment for carrying out the heat treatment method of the present invention, and carry out quenching and tempering treatment according to the heat treatment method of the present invention. The steel strip running speed in the whole heat treatment process is 17m / min, and it is heated to 860°C for austenitization. It is about 35.3s, the lead bath isothermal quenching temperature is 362°C, and the isothermal quenching time is about 24.7s. After water cooling at 60°C, it ...

Embodiment 2

[0049] A carbon-manganese steel containing the following chemical composition is selected: C: 0.29%, Si: 0.24%, Mn: 1.33%, P: 0.015%, S: 0.007%, and the balance is Fe, and the percentages are weight percentages.

[0050] The above-mentioned carbon-manganese steel hot-rolled plate with a thickness of 2.0mm is selected as a raw material, and is pickled and cold-rolled into a steel strip of 0.9×199mm. The mechanical properties after cold-rolling are: tensile strength is 975MPa, and elongation is 6%. Then enter the equipment for carrying out the heat treatment method of the present invention, carry out quenching and tempering treatment, the whole heat treatment process steel strip running speed 15m / min, be heated to 860 ℃ and carry out austenitization, holding time 40s, lead bath isothermal quenching temperature is 357 ℃, isothermal quenching time 28s, air cooling after water cooling at 60 ℃, and then the finished product is put into storage according to the traditional slitting an...

Embodiment 3

[0053] A carbon-manganese steel containing the following chemical composition is selected: C: 0.30%, Si: 0.27%, Mn: 1.50%, P: 0.012%, S: 0.009%, the balance is Fe, and the percentages are weight percentages.

[0054] The above-mentioned carbon-manganese steel hot-rolled plate with a thickness of 2.5mm was selected as a raw material, and was pickled and cold-rolled into a steel strip of 0.9×199mm. The mechanical properties after cold-rolling: the tensile strength was 970MPa, and the elongation was 7%. Then enter the equipment for carrying out the heat treatment method of the present invention, and carry out quenching and tempering treatment. The steel strip running speed is 17m / min in the whole heat treatment process, and it is heated to 860°C for austenitization. The holding time is about 35.3s, and the lead bath isothermal quenching temperature The temperature is 362°C, and the austempering time is about 24.7s. After water cooling at 60°C, it is air-cooled, and then the finish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com