Method for preparing polyester/nano calcium carbonate mixture

A nano-calcium carbonate and mixed material technology is applied in the field of polymer material preparation, which can solve the problems of dust pollution, easy re-agglomeration of nanoparticles, and small particle size of nano-calcium carbonate, so as to avoid energy consumption and avoid melting and granulation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

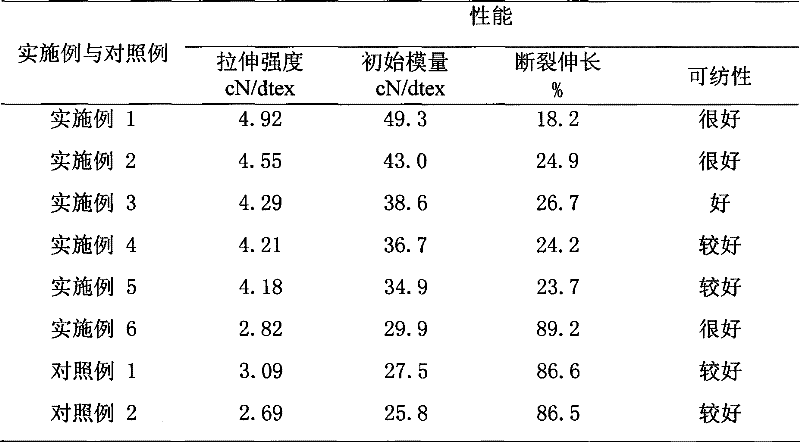

[0021] Add 3.6 kg of nano-calcium carbonate, 0.072 kg of titanate coupling agent, and 0.17 kg of composite antioxidant B225 into a high-speed mixer to neutralize 102 kg of polyethylene terephthalate slices. The speed of the high-speed mixer is 2400 rpm, the heating power is 2KW, and the temperature of the system reaches 145°C after 20 minutes. All additives are evenly coated on the polyethylene terephthalate particles, and the heating and mixing are stopped. The mixture was spun into fibers with a screw spinning machine, and the properties of the fibers are shown in Table 1.

Embodiment 2

[0023] 4.5 kg of nano-calcium carbonate, 0.09 kg of titanate coupling agent, 0.52 kg of composite antioxidant B225, and 100 kg of polyethylene terephthalate were sliced. The speed of high-speed mixing is 2400 rpm, and the heating power is 2KW. After 20 minutes, the temperature of the system reaches 145°C. All additives are evenly coated on the polyethylene terephthalate particles, and the heating and mixing are stopped. The mixture was spun into fibers with a screw spinning machine, and the properties of the fibers are shown in Table 1.

Embodiment 3

[0025] 6 kg of nano-calcium carbonate, 0.12 kg of titanate coupling agent, 0.76 kg of composite antioxidant B225, and 95 kg of polyethylene terephthalate were sliced. The speed of high-speed mixing is 2400 rpm, and the heating power is 2KW. After 20 minutes, the temperature of the system reaches 145°C. All additives are evenly coated on the polyethylene terephthalate particles, and the heating and mixing are stopped. The mixture was spun into fibers with a screw spinning machine, and the properties of the fibers are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com