Preparation method of noble metal modified titanium dioxide photocatalyst

A technology of titanium dioxide and photocatalyst, which is applied in the field of preparation of photocatalyst and can solve the problems of limiting the application of titanium dioxide and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

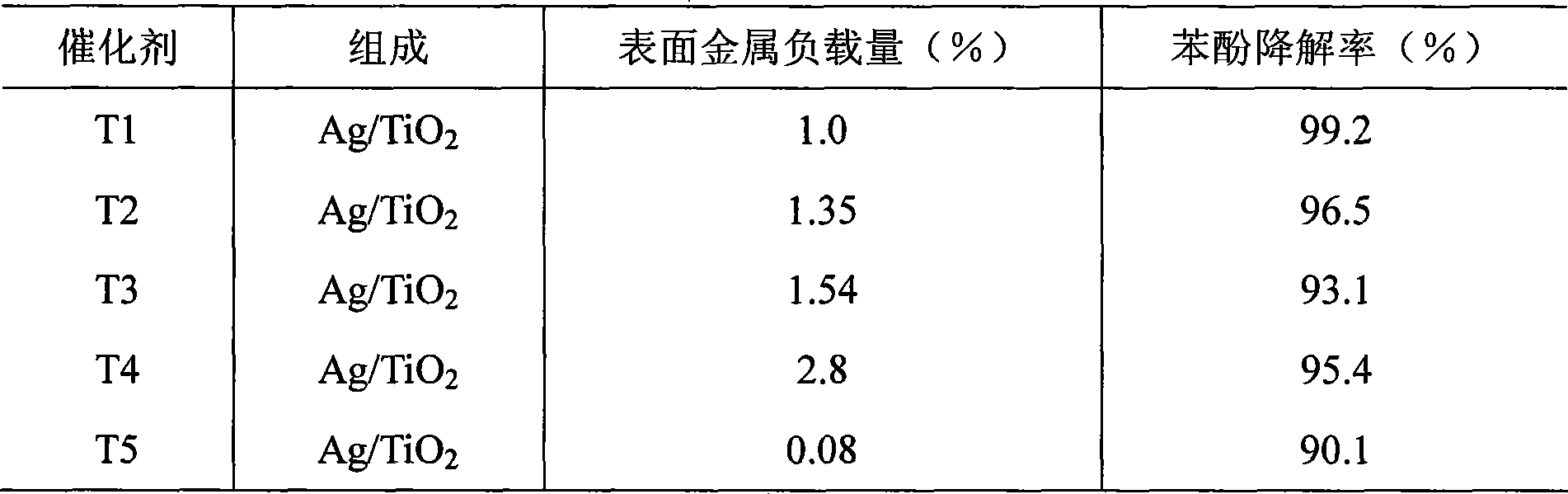

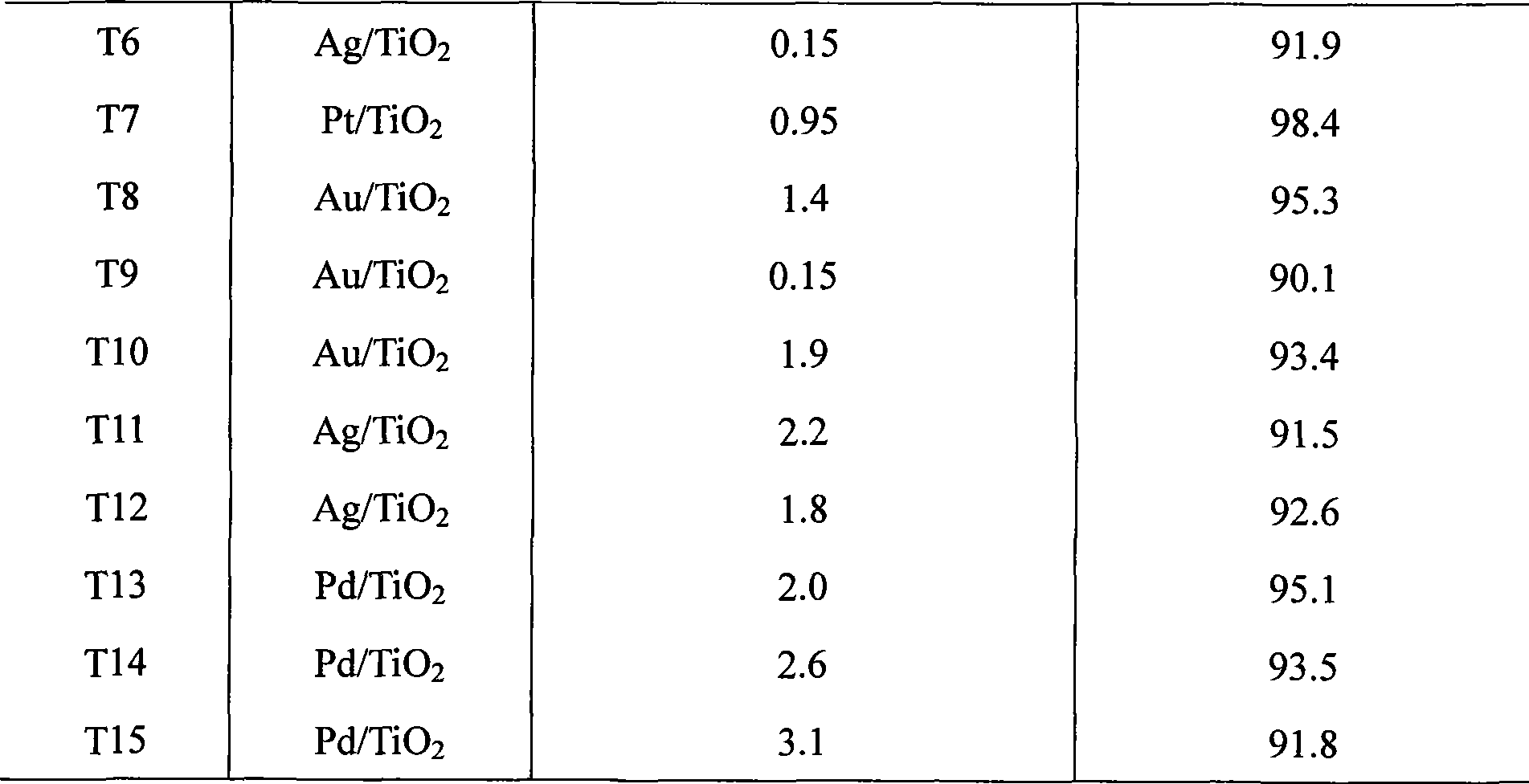

Embodiment 1

[0022] Prepare 800ml of a mixed solution containing silver nitrate 0.02g / L and phenol 0.02g / L, adjust the pH value to 4 with NaOH solution and nitric acid solution, and then mix with 0.6g anatase TiO 2 Mix (the particle size is about 300 nanometers), fully shake in the ultrasonic machine for 30 minutes, pour it into the photocatalytic reactor, and turn on the 20W ultraviolet lamp at 25°C to carry out the photocatalytic reaction for 2 hours, filter and separate the catalyst, and wash with distilled water for 3 Once, dry in an oven at 100°C for 6h to obtain a supported Ag / TiO with a silver content of 1.0wt%. 2 Catalyst, denoted as T1.

Embodiment 2

[0024] Prepare 800ml of a mixed solution containing silver nitrate 0.02g / L and acetic acid 0.005g / L, adjust the pH value to 2 with NaOH solution and acetic acid solution, and then mix with 0.4g mixed crystal TiO 2 (the particle size is about 500 nanometers) mixed, and fully shaken in the ultrasonic machine for 60 minutes, poured into the photocatalytic reactor, at 30 ° C, turn on the 20W ultraviolet lamp to carry out the photocatalytic reaction for 4 hours, filter and separate the catalyst, wash with distilled water for 3 Once, dry at 80°C for 10h in an oven to obtain a supported Ag / TiO with a silver content of 1.35wt%. 2 Catalyst, denoted as T2.

Embodiment 3

[0026] Prepare 800ml of mixed solution whose silver nitrate concentration is 1g / L and ethanol concentration is 0.5g / L, adjust the pH value to 8 with ammonia solution and nitric acid solution, and then mix with 2g anatase TiO 2 (The particle size is about 100 nanometers) mixed, and fully shaken in the ultrasonic machine for 10 minutes, poured into the photocatalytic reactor, at 20 °C, turn on the 125W UV lamp to carry out the photocatalytic reaction for 2 hours, filter and separate the catalyst, distilled water Washed 3 times and dried in an oven at 100°C for 2h to obtain a supported Ag / TiO with a silver content of 1.54wt%. 2 Catalyst, denoted as T3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com