Rotary tubular photo-catalytic reactor and its water treating method

A photocatalytic reactor and rotating drum technology, applied in the direction of light water/sewage treatment, etc., can solve problems such as affecting the processing capacity of the reactor, and achieve the effects of small footprint, low energy consumption, and fast update speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 5L of 4BS direct dye with an initial concentration of 5mg / L to the first drum type photocatalytic reactor, and after 7 hours of reaction, the decolorization rate of 4BS dye reaches 63.98%.

Embodiment 2

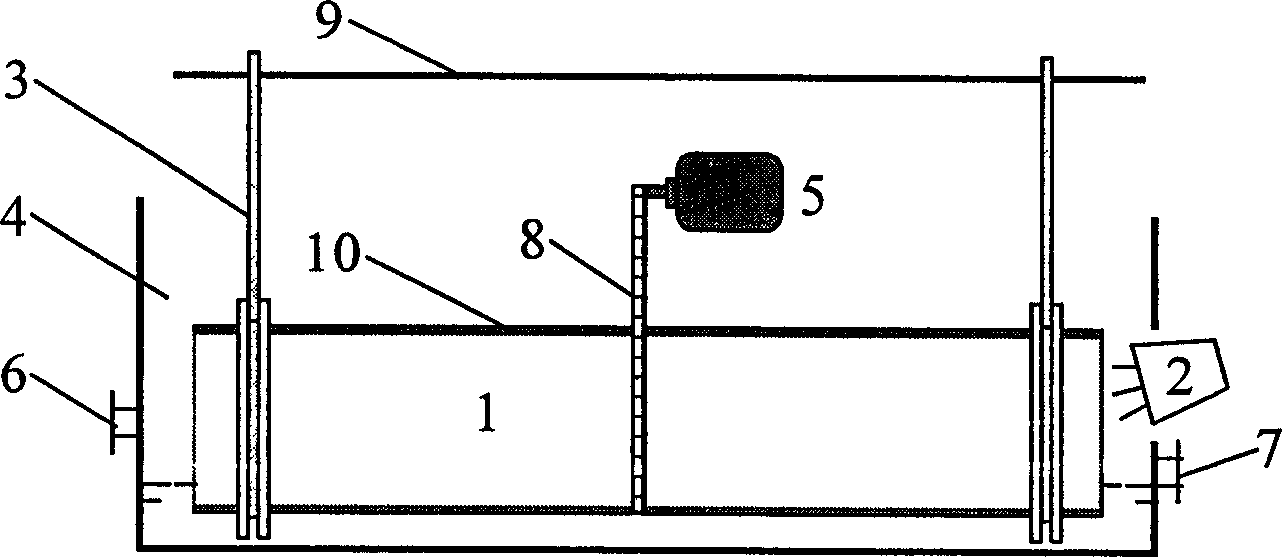

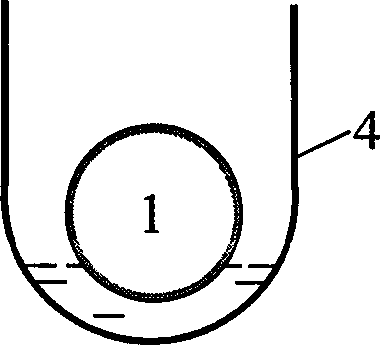

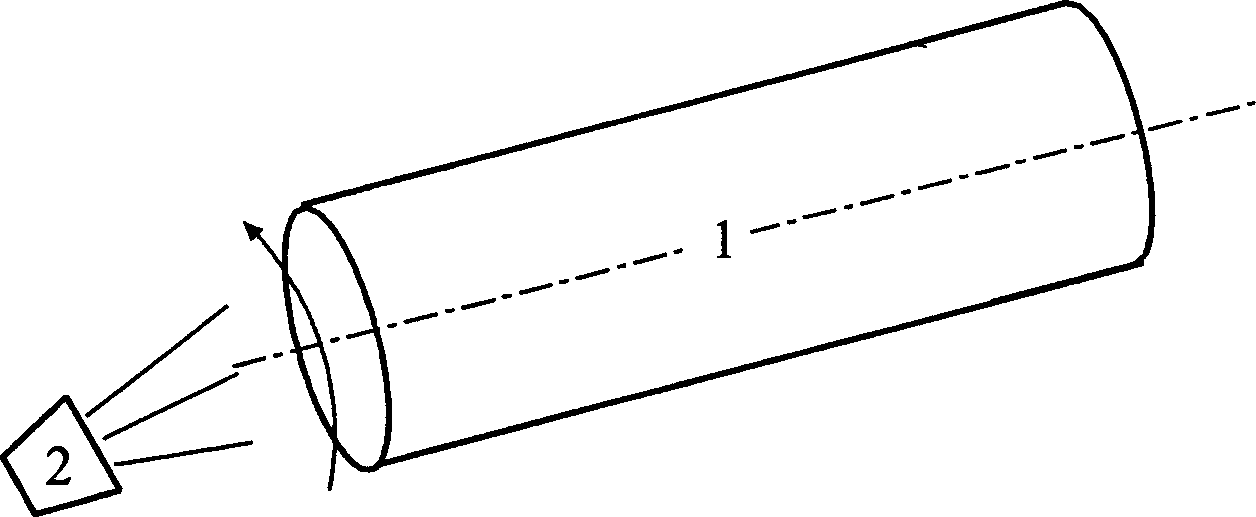

[0034] A method for treating water, comprising the steps of: (1) adding TiO containing TiO in the second drum type photocatalytic reactor 2 The waste water of catalyst fine powder, described rotary drum type photocatalytic reactor, comprises water tank 17, ultraviolet lamp 12, rotating drum 11, is provided with water inlet 14 and water outlet 15 on the water tank 17, and one end of rotating drum 11 passes central axis and The support frame 16 is connected, and the other end of the drum 11 is connected with the speed regulating motor 18 through the central shaft and the support frame 16. Parallel, a reflector 13 is arranged above the ultraviolet lamp 12; (2) 1 / 3~1 / 2 of the vertical height of the drum 11 is immersed in the waste water, and the speed regulating motor 18 is started, and the speed regulating motor drives the reactor drum 11 rotates to form a layer of liquid film with adjustable thickness on the outer surface of the drum; (3) turn on the ultraviolet lamp 12 to allow...

Embodiment 3

[0036] The steps of the method adopted are the same as in Example 2, and the dosage ratio of the catalyst in the waste water is: 1.2g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com