Miniature passive bidirectional vacuum valve

A vacuum valve and miniature technology, applied in packaging, valve details, valve device and other directions under vacuum/special atmosphere, it can solve the problems of poor sealing performance of the valve itself, and achieve the effect of easy cleaning, simple decomposition and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

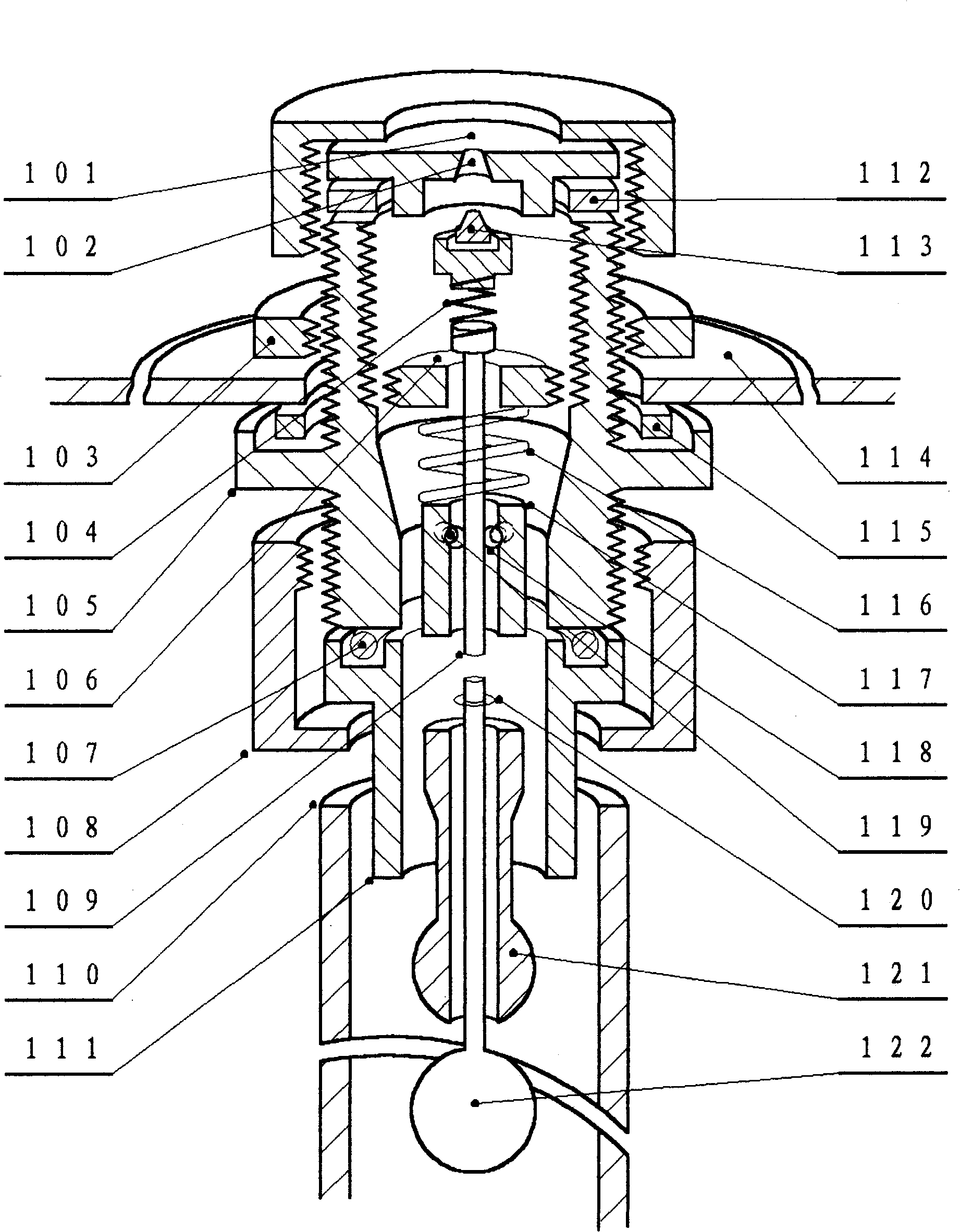

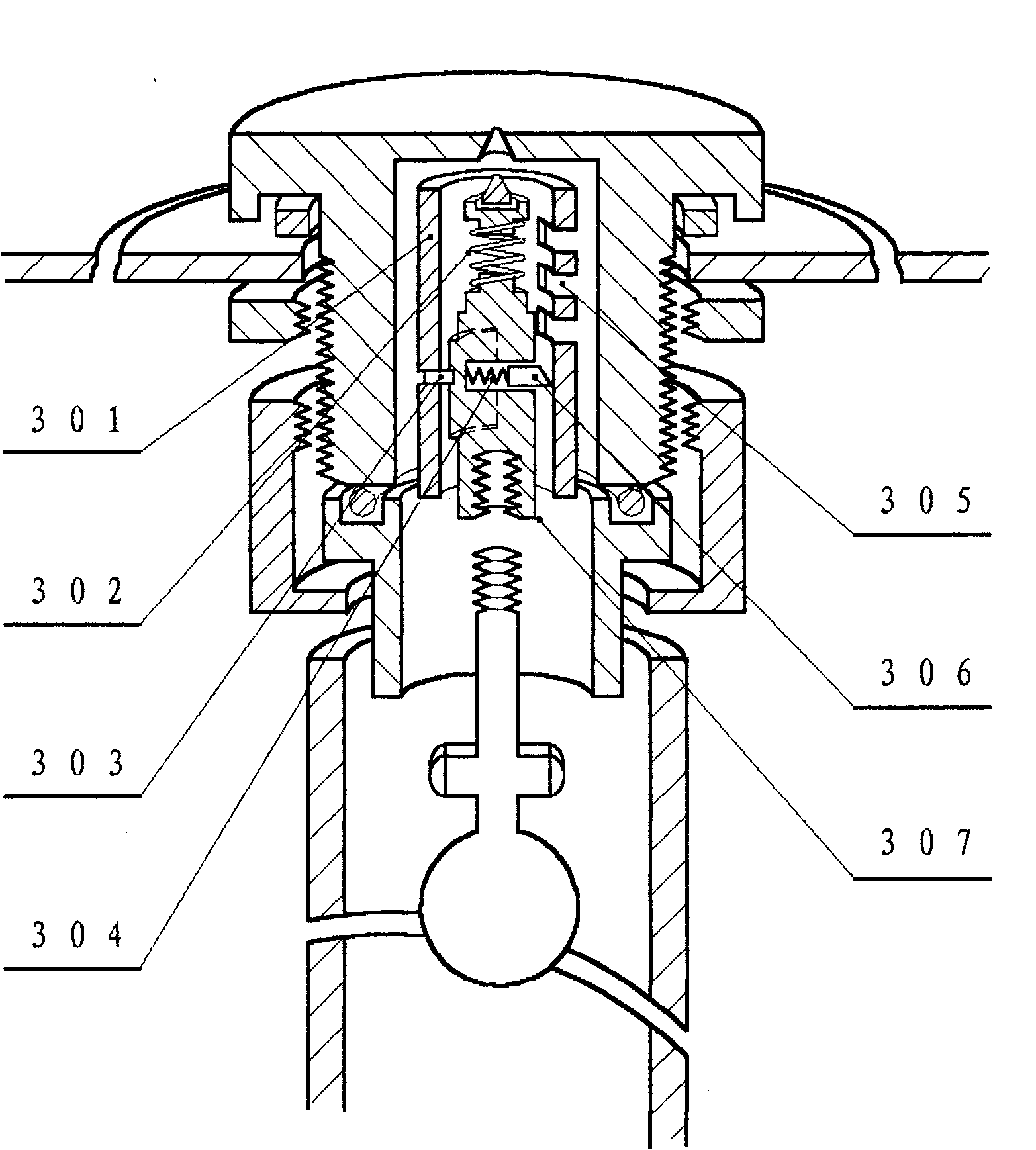

[0027] The structure of the present invention will be further described below in conjunction with the accompanying drawings. Such as Figures 1 to 4 As shown, the valve removes the exposed handle, which fundamentally eliminates the problem of air leakage in the handle shaft bypass. It is characterized by small size, no power supply, and when the valve is opened, the gas between the airtight container and the atmosphere is bidirectional, which has no impact or loss on the limited vacuum degree of the vacuum pump. Due to the long-lasting sealing and no bypass leakage during vacuum pumping, it is called a miniature passive two-way vacuum valve.

[0028] It mainly consists of a valve body, a piston (113), a two-way locking mechanism and a key. Piston (113), two-way locking mechanism and key are connected sequentially inside the valve body. Piston (113) is elastic, made of silica gel or oil-resistant and temperature-resistant rubber.

[0029] The piston rod can be single or com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com