Method for preparing nano platinum oxidation coating for high temperature alloy

A high-temperature alloy and nano-platinum technology, which is applied in the direction of metal material coating technology, coating, solid-state diffusion coating, etc., can solve the problems that there are no reports on the preparation technology of nano-platinum-aluminum coating, and achieve a simple and convenient preparation method. Effect of improving binding force and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

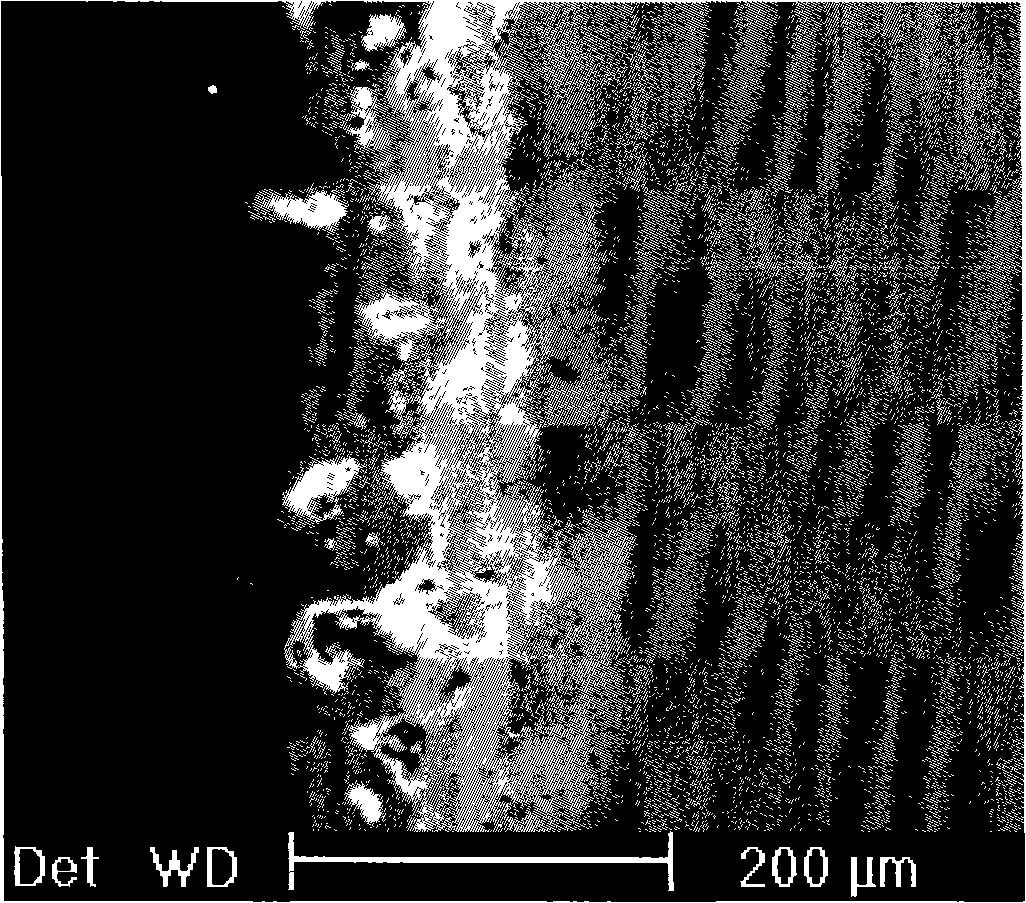

Embodiment 1

[0016] The superalloy is first surface treated, put into hydrochloric acid with a concentration of 1-10M, take it out after about 1-5min, wash it in twice distilled water and dry it. Place the treated high-temperature alloy in a platinum electroplating solution for electroplating. The platinum electroplating solution is composed of 5-40g / L chloroplatinic acid, 50-600g / L hydrochloric acid and an appropriate amount of additives (0.5-5g / L). The temperature is 50-100°C, and the pH value is 2.5-5.8. Subsequently, the obtained sample is subjected to powder embedding aluminizing treatment. The infiltrating agent is composed of aluminum powder, alumina powder and ammonium chloride. The composition of the aluminizing agent is 1-12% aluminum by weight percentage, 75-84% Aluminum oxide powder and 4-24% ammonium chloride are mixed evenly. Embed the sample in a container filled with infiltration agent, then place the aluminized container in a high-temperature resistance furnace, pass in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com